Multifunctinal interior ceramic wall tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

- Option:

- 300*600mm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

ceramic wall tiles for bathroom & kitchen for Dubai market

Advantage:

1. All ceramic wall tile are PREMIUM AAA Grade. We established an independent dept to inspect all goods before shipment.

2. OEM service: We can make your brand on the package or even on the tiles. Also, you can customize your own designs with us.

3. Special dimensions are available according to request.

4. More than ten years experience and very professional team in exporting to ensure your order more smooth.

5. On time delivery, in general 15~20 days.

6. Best service: customer can follow their order situation any time, no matter on product line, warehouse or shipment.

7. Own designer team ensure the designs are newest and adjust for pure and right color.

Package Details :

8 pcs/carton

1080 cartons/1*20 GP/with pallet

27 Ton/ 1*20 GP

Product effect:

Company information:

Our company founded in 2004,is a professional manufacturer of all types of ceramic tiles and porcelain tiles,covering an area of 180,000 square meters.Currently we have over 1000 staff,including 72 research & development talents with years'experience in this field.

With international advanced machines imported from Italy and Spain, we can provide tiles with superior quality standard. Our company obtained the ISO9001 Quality Management System Certificate,thereby ensuring that we can supply clients with a significant quality guarantee.

Moreover,we greatly pay attention to constant technical innovation.Over the past few years,we have developed a wide range of wall tiles and floor tiles.These products are available in 300*600mm,400*800mm,300*900mm,600*600mm ,800*800mmm ...

Factory show:

FAQ:

1. What is your MOQ?

MOQ: one design one container .

Decoration design: one design 1x20’GP, also can mix color in one container.

2. What is the MOQ to use customer design carton?

MOQ: 5x20'GP. if less than this qty will charge for carton design draft fee.

We have own designers to meet your requirements.

3. What is special of your tiles?

More glossy, more shine, more 170g glaze , special technology of tile body more stable.

4. How you assure the quality?

We inspect the quality during incoming material, production process, packing and loading.

5. Where is you market ?

Our main markets are North America , South America , Asia and Middle East .

6. Do you attend oversea fairs ?

Yes, we attend the fair in Dubai, Vietnam , Algeria , Korea ,Brazil and Frankfurt etc .

7. Can you make OEM ?

Yes ,we can .

8. Where is you famous customers ?

Our customers are including The Homedepot, OBI,...

9. What price you can offer?

EXW, FOB, CFR/CIF, ect

10. Do you have quality control team and designers?

Yes, we have 10 QC and 8 designers to guarantee quality and meet your colors and styles need

11. What payment you accept?

Normally By TT, L/C also acceptable.

- Q:I purchased engineered wood flooring, following manuf. requests, but it started to separate within a month. I pulled it all apart and GLUED it back down, removing the moisture foam barrier stuff. Now EVEN after glueing the flooring to the subfloor- it is still separating in places, not as many, but Dang! lol

- The reason is simple ! it is not seasoned well. hence it is shrinking. Go back to the supplier and demand rectification of the defects.

- Q:Recently, the home of the house to be renovated, people say that the floor is very important, but they do not want to use what floor, want to listen to the views of everyone

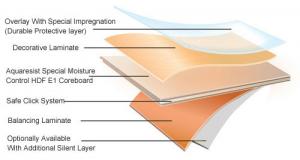

- To strengthen the floor -- a bad, no regrets. Laminate flooring is the cheapest, although its high-end products are also very expensive, said that if your unit price of 100, you can only choose her (or?) The. The floor color is rich and beautiful, who can find their love color patterns, health or do her, just as a tile, but I think the environmental protection almost, maybe I will never forget the scene not to buy a computer desk in the furniture factory to see, in addition to the floor surface is a layer of wear-resistant layer, the bottom surface is moistureproof layer, the middle is density board, density board is made of wood dregs, which has also used rubber, rubber paving, and as we all know, is the most environmentally friendly glue, and if the time is long, the surface of the layer of wear resistant layer without the floor is rubbish, hundred-percent, I have seen no wear-resisting layer, really miserable, with the apple of Sodom is not too much to describe

- Q:How to choose wood flooring

- The standard of solid wood flooring is GB/T15306-2001. Since the implementation of the standard since May 1, 2002, the original 94 standard was replaced. The new national standard has made the important revision and the supplement to the old national standard. The main content is to modify some of the size and content of the supplement, the application of the specification of the tree species and the requirements of the paint plate. At the same time, the impact toughness and abrasion resistance of the wood are eliminated.

- Q:For example: Panlong eye, disk beans.

- Classification of composite flooringCurrently on the market there are two main types of composite floors: one is a solid wood composite floor; the other is to strengthen the composite floor. These two types of composite floor has its own different characteristics, in the use and maintenance requirements are also different.

- Q:What is the difference between solid wood flooring and floor tiles

- The 5 major advantages of ceramic tile: easy to clean, simple maintenance, not easy to hide, no air pollutants; long service life, generally can use for 10 - 20 years; fire, waterproof, anti-corrosion performance is good; environmental protection. Details: if you want to place enough, then choose the floor tiles. In any building materials market, there are a variety of sizes, various colors and various patterns of floor tiles for sale. With a piece of floor tiles can spell out their vision of family life. And take care of the special floor tiles, sweep, wipe a very clean. Floor tiles do not have to worry about being wet or hard to scratch.

- Q:What is the Chinese style solid wood floor

- The highest price, wood flooring material is relatively high-end jade sandalwood, balsam, teak, rosewood and other materials, this is mainly because they have their own different from other attributes, jade sandalwood, it is even able to sink in the water, the texture is very strong; balsam, has a very unique fragrance. In fact, the jade sandalwood, balsam is material is due to its unique advantages as an additional attribute wooden floor to make it worth to rise, if it only considers the wood floor service life and durability, longan, OKAN is a very good choice.

- Q:My home shop paint free non planed wood floors, less than a month into the deformation flake, a place also raised, there was no moisture-proof pad. What is the reason for this, what is the way to fix it? Thank you

- Material problemSolid wood floor is very afraid of water is a normal thing, it is easy to cause swelling due to water absorption, deformation. Its moisture resistance is not strong, and the stability is poor under the moist environment. Therefore, the solid wood floor can not meet the water

- Q:Home decoration, intended to shop wood flooring three storey building materials city to see the floor, found a lot of solid wood flooring seller told me that the wood floor can be used wet mop, without wax today, not arching, good care and so on, this is really, the price is about 300. To 400 yuan or so, my question is always heard wood floors not wait on price...On the other hand, the solid wood flooring businesses have told me that when the floor is not playing keel, you can shop like a composite floor shop a moisture-proof pad directly after the shop, so good?

- It is said that the solid wood floor is not good, but the price is expensive, but the environmental protection aspect is very low, only then decided to have to use the three layer solid wood compound floor, this is right.

- Q:What is the difference between composite wood flooring and laminate flooring?

- Laminate flooring in the market a lot of names, according to national standards, its official name should be impregnated paper veneer laminate flooring1, excellent physical and mechanical propertiesThe first is the composite laminate flooring has high wear resistance, surface abrasion resistance is 10-30 times of ordinary paint wooden floor. The second is the product of the internal bond strength, surface bonding strength and impact toughness and other mechanical properties are better. According to the test, the surface resistance of composite reinforced wood floor is less than 1011, with good antistatic the performance, can be used as a room floor. In addition, composite wood floors have good resistance to corrosion, anti ultraviolet light pollution, cigarette burning resistance and other properties.2, there is a larger size and good dimensional stabilityTrends for large size floors and wood floors, with the size of the increase, the possibility of deformation is also increased. The composite wood floors with a high standard of material and reasonable processing method, has good dimensional stability, the floor size changes little indoor temperature and humidity caused. Low temperature radiant floor heating system architecture start with the composite wood floor is one of the most suitable floor materials.

- Q:Wood floors are generally what wood? What kind of good?

- (a) according to grade points, you can refer to the following classification:The conventional solid wood flooring wood market price interval: Maple, birch (market price of about 170-370 yuan / square meters); white Shuanmu (160-330 yuan / square meters), elm (220-360 yuan / square meters);High-grade wood: oak (220-420 yuan / square meters); jatoba (230-350 yuan / square meters), teak (270-420 yuan / square meters), Balsam (220-330 yuan / square meters)High-grade wood species: Black Walnut (300-500 yuan / square meters), Asian Pear (300-450 yuan / square meters), and ebony, rosewood, rosewood, rosewood and other valuable timber wood flooring is made, the market price at least 500 yuan / square meters above;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Multifunctinal interior ceramic wall tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

- Option:

- 300*600mm

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords