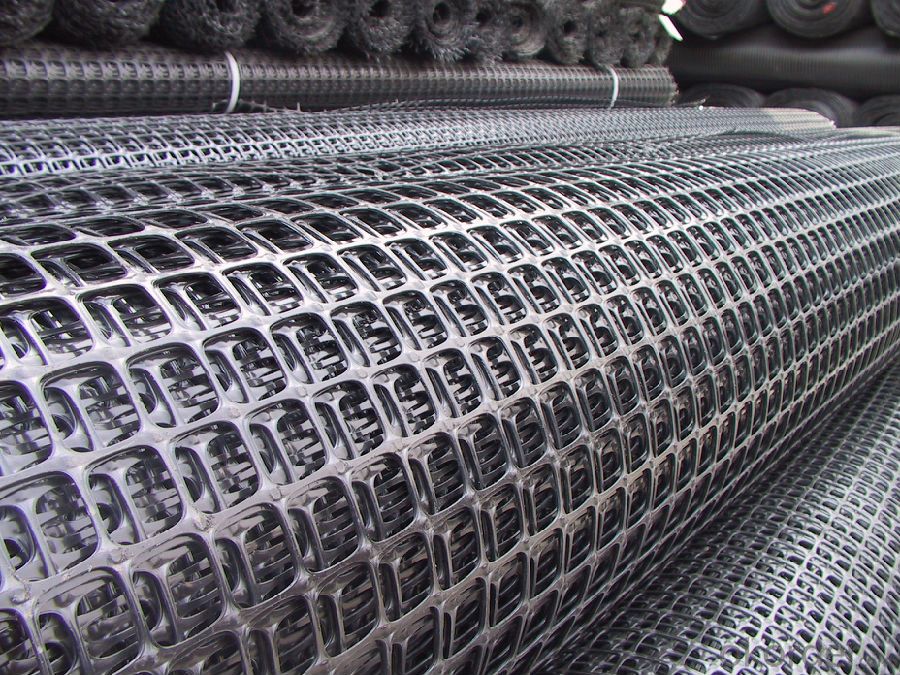

Multiaxial High strength steel-plastic Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

Product Features

1. The intensity is high, the distort is small

2. The wriggle is small

3. Anti-corrosive, the life is long, the geogrid take the plastic material as a protector, auxiliary enables it by each kind of assistant to have the antiaging, the oxidation susceptibility again, but acid proof, alkali, salt and so on adverse circumstance corrosion. Therefore, the steel models the earthwork grill to be possible to meet each kind of permanent work 100 year above use need, and the performance is superior, the size stability is good.

4. The construction is convenient, the cycle is quickly short, the cost is low: The steel plastic complex geogrid to lay down, joining, the localization to be easy, to be smooth, avoids overlapping crossover, but reduced the project cycle effectively, saved the building cost of projects 10%-50%.

Applications

Plastic geogrids can be used to enhancement of permanent bearable toft including roads and railways embankment, slopes, tunnel, airfields, parks, docks, and ground which cargo lays on and their main usage are as follows:

1. Enhance the bearing capacity of road foundation and extend the duration of roads

2. Prevent road surface from collapse, crack and being dirty

3. Be convenient for construction, time saving and cut down the cost of maintenance

4. Prevent tunnel from crack occurring

5. Further solidity slopes to proof water and soil from losses

6. Reduce the surface thickness of the ground

7. Consolidate the net for growing grass on the slopes so as to stabilization surrounding virescence

8. Be used for artificial top net of mines instead of metal ones.

Packaging & Delivery

| Packaging Details: | Rolls |

| Delivery Detail: | 20 Days |

Detiled Data

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

F&Q

1 How about the delivery time? Lead time since receipt of 30% T/T deposit payment: 3 weeks.2 What kind of payments does jenor support? T/T 3

What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4

How to deal with the sample charge?

Accordeing to our company policy, the samples are free, we only charge the freight fee.

And we will return the freight fee If you set the order .

5

Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6

Can you tell me your main customers?

That's our customers' privacy, we should protect their information.

At the same time, please rest assured that your information is also safe here.

- Q:Can geogrids be used in soil reinforcement for oil and gas pipeline projects?

- Yes, geogrids can be used in soil reinforcement for oil and gas pipeline projects. Geogrids are often employed in this context to provide stabilization and reinforcement to the soil, improving its load-bearing capacity and preventing soil erosion. This helps ensure the integrity and longevity of the pipeline system, making geogrids a valuable solution for soil reinforcement in oil and gas pipeline projects.

- Q:Can geogrids be used in pond liners?

- Yes, geogrids can be used in pond liners. Geogrids are often used as a reinforcement material in the construction of pond liners to enhance their stability, prevent soil erosion, and increase their overall strength and durability.

- Q:Do geogrids provide reinforcement to geosynthetic asphalt liners in landfill covers?

- Yes, geogrids do provide reinforcement to geosynthetic asphalt liners in landfill covers.

- Q:How do geogrids enhance the performance of geosynthetic clay liner erosion control blankets?

- Geogrids enhance the performance of geosynthetic clay liner erosion control blankets by providing additional reinforcement and stability. They help to distribute the load and prevent the geosynthetic clay liner from shifting or sliding, thereby increasing its resistance to erosion.

- Q:How do geogrids help in reducing soil compaction?

- Geogrids help in reducing soil compaction by distributing the load from traffic or construction equipment more evenly across the soil surface. This helps to minimize the concentration of pressure on specific areas, preventing excessive compaction and allowing for better soil structure and drainage.

- Q:What are the benefits of using geogrids in retaining walls?

- The benefits of using geogrids in retaining walls include increased stability, improved load-bearing capacity, reduced soil erosion, and longevity of the structure. Geogrids reinforce the soil, preventing it from sliding or collapsing under pressure, making the retaining wall more durable and resilient. Additionally, geogrids distribute the loads evenly, reducing the risk of settlement and enhancing the overall performance of the wall. They also enhance drainage and filtration, minimizing water buildup behind the wall and preventing soil erosion. Overall, geogrids help to ensure the longevity and effectiveness of retaining walls.

- Q:Geogrid GSZ 100 50/PP what does it mean

- The rear PP should be the PP solder grid.

- Q:Are geogrids resistant to microbial attack?

- Yes, geogrids are typically resistant to microbial attack.

- Q:What are the typical applications of geogrids?

- Geogrids are commonly used in civil engineering and construction projects for various applications such as soil stabilization, reinforcement of retaining walls, slope stabilization, pavement reinforcement, and erosion control. These grids provide strength and stability to soils, reducing the chances of soil movement and improving the overall stability and longevity of the structure.

- Q:What are the limitations of geogrids?

- Geogrids have a few limitations. Firstly, they are not suitable for all types of soil and terrain conditions. They are most effective in soils with good particle interlock and cohesion. Secondly, geogrids are not effective in situations where there is high water flow or erosion potential as they do not provide sufficient protection against these forces. Additionally, geogrids may have limited strength in certain applications, such as heavy load-bearing scenarios, and may require additional reinforcement. Lastly, the installation and maintenance of geogrids can be complex and costly, requiring skilled labor and regular inspections to ensure proper functioning.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Multiaxial High strength steel-plastic Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords