Multi-Ply EP/NNN/CC Coal Mine Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Multi-Ply EP/NNN/CC Coal Mine Conveyor Belt

Description of Rubber Conveyor Belt

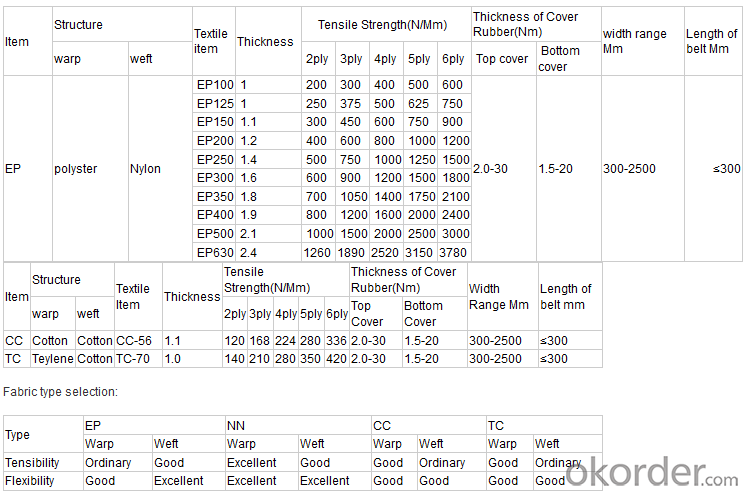

The polyester conveying belt is also called EP conveying belt. Its framework material is the polyester canvas interwoven with meridian terylene and latitudinal polyamide fiber. It is characterized with excellent endurance, good water-resistance, no lowering of strength in humidity, mildewproof, and high load of initial models. It is applicable to convey materials in medium and long distance, with high-load, and at high speed.

EP Conveyor Belt is also known as Polyester Conveyor Belt. These EP conveyor belts & Heavy Duty Conveyor Belt are compatible with long distance conveying with high load, high speed conveying, good flexing capacity, trough able, heat resistant, low lad elongation and speed & impact.

Polyester Belting is mainly used in conveying powdery and granular materials etc.EP conveyor belts keep high intensity in humidity condition, which is helpful for transferring the washy material or working on wet condition.

USAGE: mining, metallurgical industry and architectural industry, ports etc.

Pictures of Rubber Conveyor Belt

Pls contact me freely if any inquiry or questions,thank you!

- Q:How to distinguish between plastic products and rubber products, toys?

- There are several ways to distinguish between plastic and rubber products:1, color: plastic products, relatively transparent color, relatively strong, and rubber products are relatively poor transparency;2, thickness: plastic product thickness than rubber products thin;3 hardness: general plastic products than rubber products slightly hard;4: texture: plastic products are more smooth or microstrip lines, and rubber products on the surface of some of the same as human skin, texture deeper or more rough;5, taste: plastic taste, the taste of micro strip plastic, and rubber products are micro rubber rubber flavor;6, weight: general plastic products will be slightly lighter than rubber products.

- Q:Is it necessary to use rubber products for steel structure buildings?

- There must be a rubber cushion for the gear of the crane beam, and there is also a rubber cushion between the crane track and the crane beam. Of course, not all deformation joints are rubber, depending on how to choose the design node.

- Q:What adhesive does rubber and wood have better glue?

- Glue is the intermediate between two kinds of materials. It is a kind of fine chemical, which is mainly made of sticky material, physical form, hardening method and classified material. There is a common instant glue (502 common ethyl cyanoacrylate adhesive is a powerful instant), epoxy resin adhesive, anaerobic glue, UV glue (UV curing), hot melt adhesive, pressure-sensitive adhesive, latex etc..

- Q:Why is rubber forest a green desert?

- Long ago, the people have the knowledge of the use of wild rubber. Before Columbo came to the new world, no one outside the Americas knew that there was a species called rubber, and never thought that there would be a magical liquid out of the tree trunk that could change the progress of human civilization one day.

- Q:What's the difference between plastic and rubber?

- 1. the main component of plastic raw material is graphite2.: plastic raw material is made of polymer synthetic resin (polymer) as main ingredients. The infiltration of various auxiliary materials or additives, the pressure at a certain temperature, and has the plasticity and fluidity, can be molded into shape and maintain the same shape of material under certain conditions.

- Q:How are rubber wires processed?

- Rubber wire, mainly refers to the insulating layer and the jacket is made of natural rubber, styrene butadiene rubber, ethylene propylene rubber, in addition to meet the insulation properties and physical mechanical properties, aging resistance, abrasion resistance requirements, some products require oil resistant, flame retardant.

- Q:What are the causes of cracks in vulcanized rubber products?

- The curing temperature is too high, pocket, self adhesive rubber products of poor liquidity

- Q:What is the difference between vulcanized rubber and butyl rubber?

- Nitrile butadiene rubber is prepared by polymerization of butadiene and acrylonitrile by emulsion polymerization. Nitrile rubber is mainly produced by low temperature emulsion polymerization. It has excellent oil resistance, high wear resistance, good heat resistance and strong adhesive force. Its disadvantage is poor resistance to low temperature, poor ozone resistance

- Q:How do soft silicone rubber print?

- Silicone ink, printed with silk screen just fineSoft silica gel, also called soft conductive silica gel, is a kind of heat transfer interface material. It is a sheet material. It can be cut arbitrarily according to the size and shape of the heating power. It has good thermal conductivity and insulation characteristics

- Q:What does rubber mean?

- High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Multi-Ply EP/NNN/CC Coal Mine Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords