Mounting System Single Pile System VGPBE2

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Cost competitive: all components are in standard sizes & mass produced

Free weilding: all components connected with fasteners

Easy installation: simplified structure, could be pre-assembled

Hot-dip galvanized: high corrosion resistent

Adaptable for all kinds of soil condition

Recyclable & zero pollution

Long service life

Advantages

1)Quick installation: with high degree of pre-installed rate, the system could be easily installed by using galvanized carbon steel rails for PV Stent, and specially designed connection parts of the PV bracket, which could reduce installation time and cost greatly.

2)Offer unmatched durability: with all structural components comprised of high class stainless steel and anodized aluminum alloy, it is designed for 25 years service life and backed by 15 years warranty.

3)Stand up to extreme weather: The SuninTek solar mount is designed to stand up to the extreme weather complied with the AS/NZ 1170 and other international structure load standard by the skilled engineer. The main support components also have been tested to guarantee its structure and load-carrying capacity.

4)Provide broad installation flexibility: These systems accommodate most commercially available framed solar panels , and they can scale easily from small to large, multi-megawatt installations.

5)Diversified Application: The PV mounting system produced can be adopted by various types of PV cells panels which you can find in the market. It can serve for both mini solar power system and huge plant with megawatt capability.

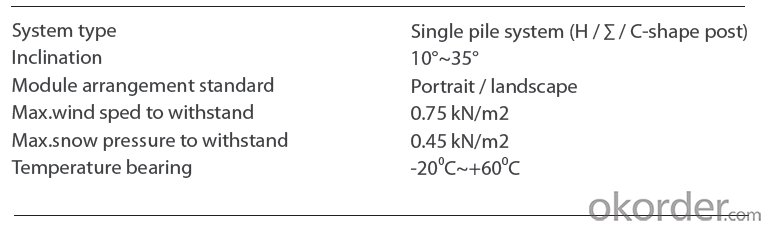

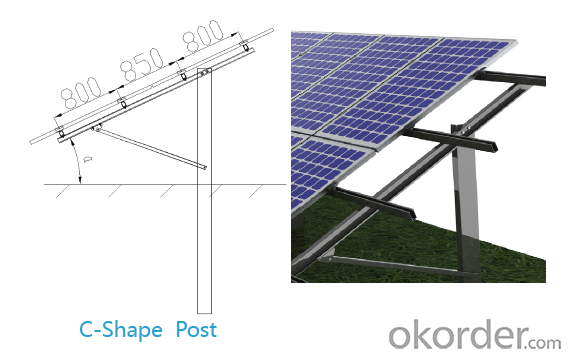

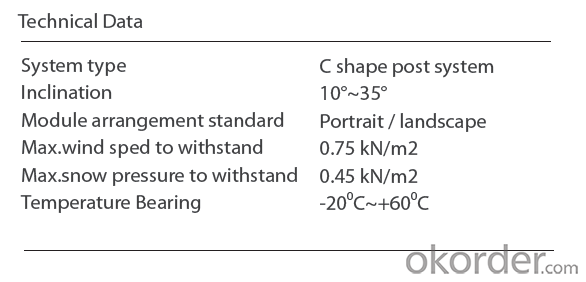

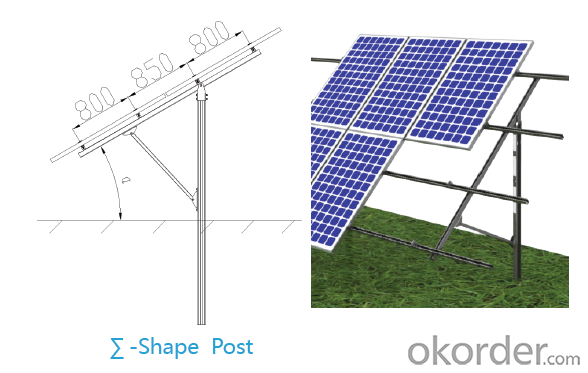

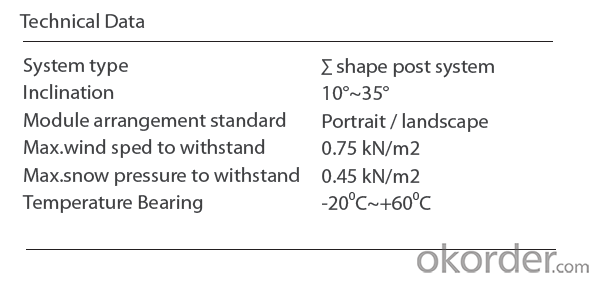

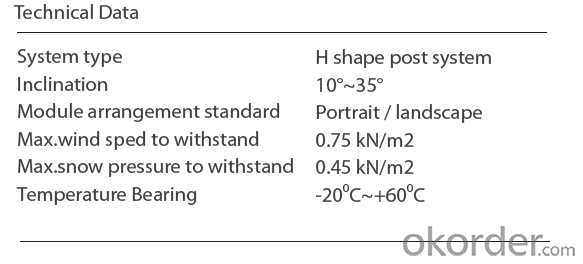

Technical Data

FAQ

I..Will you focus on the safety of the goods during transportation?

Yes, Safety of the cargo is the primary element that we would consider on transportation.

II..How would guarantee the quality will meet the requirements of your clients?

Before shipment, we will have inspection for each batch of goods.

III..What certificates do you have?

IEC,UL,TUV,CSA,etc.

IV..Can you do OEM according to clients’ requirements?

Yes, we have our own brand while we can provide OEM service.

- Q:Are there any specific requirements for installing a solar mounting system on a green roof?

- Yes, there are specific requirements for installing a solar mounting system on a green roof. Firstly, the green roof should be able to support the additional weight of the solar panels and their mounting system. The structural integrity of the roof must be assessed by a professional engineer to ensure it can handle the load. Additionally, the green roof should have a suitable slope and orientation to maximize solar exposure. Proper waterproofing and drainage systems are crucial to prevent water leakage and damage to the roof. It is essential to consult with experts in both green roof and solar panel installation to ensure compliance with building codes and regulations.

- Q:Can solar mounting systems be installed on green roofs?

- Yes, solar mounting systems can be installed on green roofs. Green roofs are designed to support the weight of vegetation and provide insulation, and with proper planning and engineering, solar panels can be safely installed on top of them. This allows for the dual benefits of utilizing renewable energy while maximizing the use of available space.

- Q:Can a solar mounting system be installed on a rooftop with a corrugated metal roof?

- Yes, a solar mounting system can be installed on a rooftop with a corrugated metal roof. The corrugated metal roof provides a sturdy and durable surface for the solar panels to be securely mounted, ensuring proper installation and efficient generation of solar energy.

- Q:Are there any specific installation regulations for solar mounting systems?

- Yes, there are specific installation regulations for solar mounting systems. These regulations vary by country and sometimes even by region within a country. They typically include guidelines for structural design, wind and snow loads, electrical wiring, grounding, and fire safety. It is important to adhere to these regulations to ensure the safe and efficient installation of solar mounting systems.

- Q:Can a solar mounting system be installed on a desert or arid region?

- Yes, a solar mounting system can be installed on a desert or arid region. In fact, deserts are often considered ideal locations for solar installations due to their high solar irradiance and vast open spaces. However, it is important to consider factors such as extreme temperatures, sandstorms, and dust accumulation, which may require specialized design and maintenance of the mounting system to ensure optimal performance and durability.

- Q:Can a solar mounting system be installed on a casino or gaming facility?

- Yes, a solar mounting system can be installed on a casino or gaming facility. The installation of solar panels on such facilities can help reduce their carbon footprint, lower energy costs, and showcase their commitment to sustainability.

- Q:Can a solar mounting system be installed on a rooftop with a torch-down roof?

- Yes, a solar mounting system can be installed on a rooftop with a torch-down roof. However, it is important to hire a professional installer who is experienced in working with torch-down roofs to ensure proper installation and prevent any damage to the roof.

- Q:Can a solar mounting system be used in areas with limited access to net metering programs?

- Yes, a solar mounting system can still be used in areas with limited access to net metering programs. Net metering allows homeowners to earn credits for excess energy they produce and feed back into the grid. However, even without net metering, a solar mounting system can still provide benefits such as reducing reliance on the grid, lowering electricity bills, and potentially earning incentives or tax credits from local or state governments. Additionally, excess energy can be stored in battery storage systems for use during periods of low sunlight or high energy demand.

- Q:Can a solar mounting system be used on commercial buildings?

- Yes, a solar mounting system can be used on commercial buildings. In fact, solar panels are commonly installed on commercial buildings to harness solar energy and reduce electricity costs. The mounting system ensures secure and efficient installation of the panels on the building's rooftop or façade.

- Q:Can a solar mounting system be installed in a high-wind or hurricane-prone area?

- Yes, a solar mounting system can be installed in a high-wind or hurricane-prone area. However, it is crucial to ensure that the mounting system is designed and engineered to withstand the specific wind loads and conditions of the area. Additionally, proper installation techniques, including the use of reinforced anchors and secure attachments, are essential for the stability and safety of the system in such environments.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mounting System Single Pile System VGPBE2

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords