Monofilament Bag 100cmx120cm HDPE Material UV treatment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 950000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

About the enterprise group - CNBM Group

China National Building Material Group Corporation (CNBM),is the largest building materials and equipment group in China.

• Established in 1984 with approval from the State Council

• A Central Enterprise under direct supervision of SASAC in 2003

• Over 100,000 employees

• 20 companies under direct management

• Among which 6 were listed companies, including 2 overseas listed.

Material: polyethyelene(HDPE)

Product Name: Date plam bag

1.widely used packing dates

2.durable,fashionable,

3.recyclable

4.environment-friendly products.

Material: polyethyelene(HDPE)

Specifications:

PE date bags

Made by Virgin HDPE

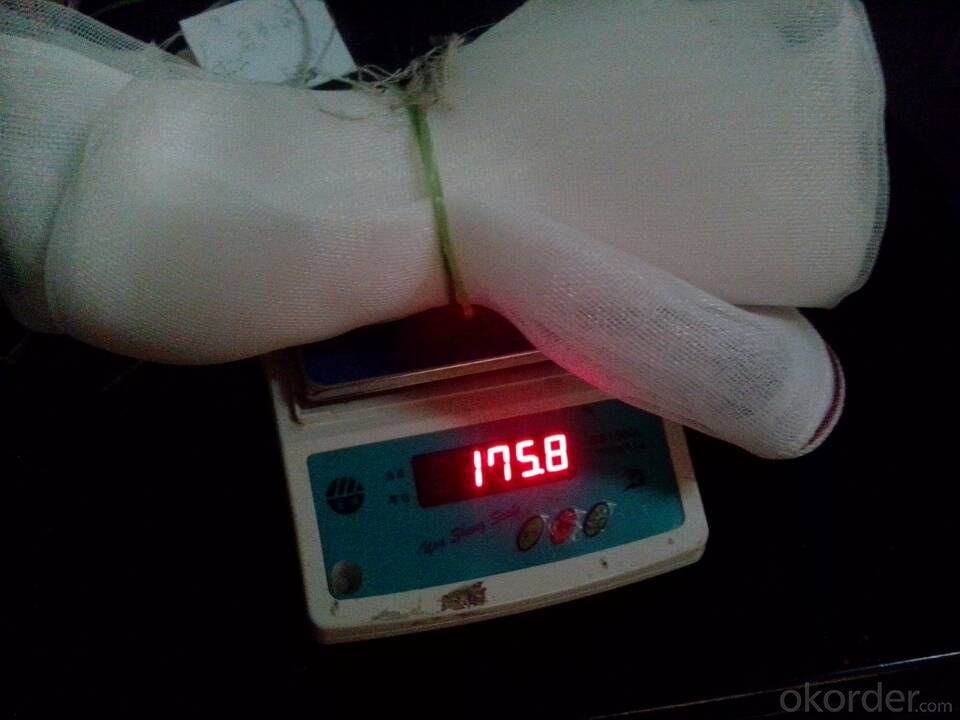

Weight:170g,175g 180g 220g 225g 280g 470g

Size: 120x100cm,100x400cm,90x140cm,90x120cm,105x135cm

Color: Green,Black, White

Packing:500pcs/bale

16tons/40'HQ

Production capacity:2x40'HQ/month

Delivery time: About 15 days/40'HQ

Payment Terms: 30% prepayment before production, 70% against B/L copy.

We would like to provide you PE date bags with good quality ,large quantity and lowest price.

Expect to cooperate with you. If you are interested in our products, please feel free to contact us for more information.

- Q:How many kinds of packing bags are there in the packaged foods?

- PE's softness and mechanical properties are worse than those of PP. It represents shopping bags, plastic wrap, garbage bags and so on.PP is stiffer, anisotropic (with a notch that is easily ripped), has good mechanical properties, and is superior to PE in high-temperature performance, representing bread bags.I wonder if this answer has met your requirement.

- Q:Three layer coextrusion material for packaging bags

- Five layer co extruded films composed of outer layer of multi ester copolymer, high mechanical strength, the second layer is ethylene methacrylate polymer, the third layer is the fourth layer of polyethylene, polyethylene, the inner layer is modified with ethylene propylene polymer. Five layer co extruded films performance of each layer as outer layer: providing excellent heat sealing and protection, good printing performance; the second layer is connected with the outer layer and third layer; third layer: providing vapor barrier and softness; fourth layer: connection layer and the third layer; inner layer: non-toxic, with compatibility infusion product good, excellent heat sealing and buffering external impact.

- Q:What are the requirements of the mark on the cement packing bag?

- The cement packing bags shall clearly indicate the standards of implementation, cement varieties, codes, strength levels, producers' names, production licence marks (QS) and serial numbers, serial numbers, date of packing and net contents. Bags on both sides should be based on the varieties of cement with different color printing name and cement strength grade, Portland cement and ordinary portland cement Portland slag cement by using red, blue gray volcano; Portland cement and Portland fly-ash composite silicate cement by sleep and black or blue..

- Q:Which kind of transparent vacuum packing bag 16 wire and 24 wire?

- Suitable for your product packaging, like food packaging, of course, thin, see the product, electronic or hardware thick, anti puncture, of course, does not necessarily have to be very thick, suitable for good

- Q:How much is the 1 wire in the food packing bag printing industry?

- 1 wire =0.01 mm, refers to the thickness of the bag units!

- Q:What's bread packing? Polyethylene film, waterproof cellophane, etc.

- The utility model has the advantages that can be repeatedly used, easy to get a longer shelf life of bread to marry, and don't need strapping, can take the heat sealing with metal or plastic coated Sizha live bag, bag packaging has knot with polypropylene plastic bags of bread.

- Q:Can food wrap be heated in a microwave oven?

- There are two sides to consider1. sealed pockets are heated in a microwave oven, and the pressure in the bag is too large to explode! There are all the instructions on the microwave (as well as the eggs, and a hole). The microwave food I eat is also packed in plastic bags, but there's always room for gas2. material of packing bagGeneral contact with food bags, requirements are made of polyethylene (non-toxic, burning candles oil smell), general temperature 130 degrees, this pocket no problem (including the regular supermarket to buy plastic wrap and plastic wrap)However, there are a lot of cheap pocket (for example in the market and vest bag, supermarket cashier for plastic bags) are made of PVC, and can not contact with recycled plastic food; do not to mention (characteristics: cheap, taste, burning acrid smell)And, if it's made of polyethylene, don't heat it up with high oil food

- Q:How are food bags made out?

- Copperplate etching: that is, according to the design confirmation of the food packing bag, the copperplate needed for the food packing press is made. The version is a cylinder, and is a set of not a single root, the specific size, the number of versions, according to the previous package design to determine. One color has to make a copperplate, if there are 5 colors, you have to do 5 copperplate, of course, sometimes can also be common edition.

- Q:What is the material of detergent bag?

- Most of these bags are made of PP, PE, OPP, BOPP plastic raw materials. In general, families rarely recycle, just waste or garbage.

- Q:What are the soft and hard sides of plastic bags? Material or process technology?

- The quality of plastic packaging is determined by both the material and the process. The material is no better than the good one. But the hardness of plastic is not a decisive factor in determining the quality of plastic, mainly to see what the use of what needs to keep products

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Monofilament Bag 100cmx120cm HDPE Material UV treatment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 950000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords