Monocrystalline Sillicon Solar Panel Industral Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 watt

- Supply Capability:

- 100000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Production description

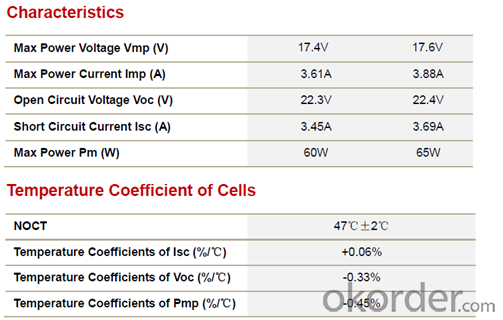

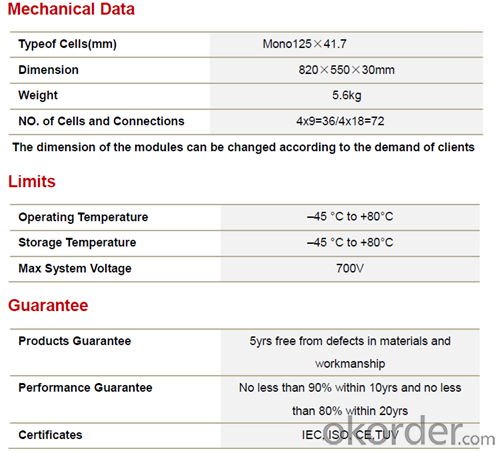

Monocrystalline Silicon Solar Panel (60-65W)

• 10 years 90% output warranty

• 20 years 80% output warranty

• High conversion efficiency mono/poly-crystalline amorphous silicon solar cells

• Modules incorporate high performance bypass diodes to minimize the power drop caused by shading

• High transmittance, low-iron tempered glass

• High performance EVA encapsulate to prevent destroying and water.

• AI frame: without screw, corner connection. 8 holes on the frame can be installed easily

• Good performance of preventing from atrocious weather such as wind and hails

• Certifications: CE IEC TUV VDE UL, Class I

Details

Images

FAQ

We have organized several common questions for our clients,may help you sincerely:

1.What price for each watt?

It depends on the quantity, delivery date and payment terms,

2.How do you pack your products?

We have rich experience on how to pack the panels to make sure the safety on shipment when it arrives at the destination.

- Q:Can solar panels be used for powering wireless charging stations?

- Yes, solar panels can be used to power wireless charging stations. Solar panels convert sunlight into electricity, which can be used to charge devices wirelessly through induction or magnetic resonance. By harnessing solar energy, wireless charging stations can operate independently and sustainably, making them an environmentally friendly option.

- Q:am having a 75 watts siemens solar panel and is giving me 2.89volts during bright light, i wanted to know can this be used to charge 00Am/hr battery?

- Many of the panels used on homes are designed to produce 2 volts DC. 0 of them wired in a series would produce 20 volts DC. An inverter is used to change the DC voltage to AC. The other aspect of electricity is amperage. With electrical units wired in series the voltage is added. When they are wired in parallel the amperage is added. The Volts x Amps produced will give you the wattage. A wise homeowner will examine their electric bills or the equipment used to determine their demand. They will consult tables that let them know how much sunlight their area receives each year as this will alter the rated performance of the panels. Then they will try and determine how much of the demand they want to fill. 80% may be economical. Then they also want to determine what they will do with excess electricity that may be produced during the summer months of intense sun and how they will supply the shortfall of low sun winter months. From all this they will determine the number of solar panels they need to purchase.

- Q:What is a good sight that I could go to about installing solar panels and all of the considerations of it?

- That okorder /... In both cases I would recommend you call to get specifics before ordering anything.

- Q:how to use a motor with solar panel

- photograph voltaic capability is somewhat fluctuating capability source and so it may be greater advantageous if u could save the photograph voltaic capability in a battery. The battery is then related to the motor. returned connect the motor with a zener diode to the photograph voltaic panel because of the fact if u dont u could have a case of decrease back emf producing from the motor and getting discharged interior the photograph voltaic panel that could injury it. further the battery additionally ought to be having a diode circuit which might avert it style discharging into the photograph voltaic panel. hoping that this facilitates..

- Q:I hooked up a 2V solar panel to a small relay. The relay switches at 9V. When I have light shining on the panel it puts out aorund 3-4V, but when I hook it up directly to the relay it drops to V and doesn't switch the relay. Why? and How do I fix it?-2V Mono-Crystalline Solar Panel -JWD 7 4 reed relay

- Do you know what is the rated Peak watts of the solar cell and the current needed to operate the relay. The power needed to operate the relay can be found from 9V * operating current, and that should be lower than the peak output power of the cell (perhaps significantly less as the peak power is produced only at high solar radiation levels. Another factor is whether the curves for the solar cell match the load. Typically the solar cells have a knee type diagram for the VI relationship, and that is why they need Maximum Power Point trackers to deliver a good power output.

- Q:trees vs solar panels who would win?

- If it was a physical battle, solar panels. It's like burning ants with a magnifying glass. Aim the solar panel at the trees and you have a forest fire.

- Q:I wanna start going green, you know like solar panels, wind turbines, etc. but where I live the companies that install the free solar panels in exchange for the subsidiaries aren't available. To start off I was just looking for a single panel I could drill into my roof and wire it to an outlet just for small thinks like charging my phone and a fan maybe. If anybody can understand my crazy idea please answer with links to where I can find these things. Thanks!

- That's okorder /

- Q:I have two solar panels and I have measured that they produce V by themselves. I am trying to generate .5V, but whenever I hook them up in parallel I get something like .02V. What it happening?

- . You want series, not parallel. (Add the voltages. Coonect '+' of the first to '-' of the next, and take your feed from the extreme ends.) 2. if you parallel them and you get less voltage than one alone, you got your polarity crossed up and are reading the difference between them.

- Q:I have an inverter and a battery 20 Amperes.Daily sun shine approx. 7 Hours.Do I need to buy anything or should I connect the solar panel to the Battery direct?

- connect the solar panel to the Battery direct during the day time that's how it works in ALL situations !

- Q:I want to plug my solar system battery bank into my transfer switch on my cabin when not using a generator. The transfer switch will handle 220 volt from my generator. How do I get a 220 volt inverter that runs 60 hz or do all of them run 50 hz.I see plenty of 20 volt 60 hz. I'm at the point of needing to order one and I'm not sure.

- Investors in this ground-breaking technology include Rockport Capital Partners, Third Point Ventures and Applied Ventures, the venture capital arm of solar equipment manufacturer Applied Materials. Enphase Energy's CEO Paul Nahi said the company raised money earlier than expected due to strong demand for its microinverters. So what are these microinverters? The Enphase Micro-inverter shifts DC to AC conversion from a large, centralized inverter to a compact unit attached directly to each solar module in the power system. Distributing the conversion process to each module makes the entire solar power system more productive, reliable, and smarter than traditional solar panel inverter systems. Usually, one single inverter is dedicated to a rooftop array of panels for a homeowner. Enphase Energy, however, have built a DC-to-AC inverter that is placed on each single panel. This makes it more reliable than a centralized inverter and more efficient, so panels can generate more electricity, Nahi said. Enphase has already started shipping its microinverters and has tied up deals with several panel distributors and installers. The future of inverters? Enphase Energy has been able to improve the DC-to-AC conversion efficiency to around 95%. Because of this, Nahi predicted more companies will turn to decentralized inverters. There's been very little question on the benefits of microinverters, but people didn't think it was possible to get the efficiency levels required, he said. Now it seems that they have. If you are looking for high quality, low price solar panel inverters please visit my UK store by clicking here. For our US store click here. To return to our solar power news page. To return to our Total Solar Energy home page.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Monocrystalline Sillicon Solar Panel Industral Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 watt

- Supply Capability:

- 100000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products