Monocrystalline Silicon Solar Panel 200W Round

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Solar Module Description

CNBM Solar's photovoltaic module is designed for designed for large electrical power requirement. It is the optimal choice for both on-grid and off-grid power systems. CNBM Solar offers high performance of power per square foot of solar array.

2.Main Features of the Solar Module

Solar Cell: High efficency crystalline solar cell. Even if under the weak light, the solar module can produce maximum power output.

Tempered glass: Anti-reflecting coating and high transmission rate glass increase the power output and mechanical strength of solar module.

EVA and TPT: Using high quality EVA and TPT to prevent destroying and water.

Strong aluminum frames to strengthen the load hold and to stand against high wind.

Junction box: Multi function junction box with water proof.

Long lifetime: ≥25 years; Less power decrease.

Good performance of preventing from atrocious weather such as wind and hails.

Resisting moisture and etching effectively, not effected by geology.

The certificate issued by international authority: UL, TUV, IEC, VDE, CE.

Quick Details

| Place of Origin: | Zhejiang China (Mainland) | Brand Name: | DEJIE | Model Number: | DJ-SP |

| Material: | Polycrystalline Silicon | Size: | 54*31*2.8mm | Number of Cells: | 10pcs |

| Max. Power: | 0.17w | materials: | epoxy resin |

Packaging & Delivery

| Packaging Detail: | Bubble bag outer Carton |

| Delivery Detail: | 10days |

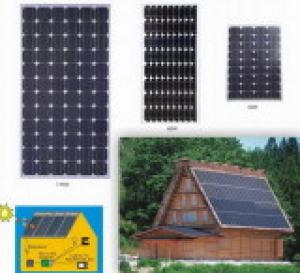

3.Solar Module Images

4.Solar Module Specification

1: Long Service Life

2: High Efficiency Solar Cells

3:RoHS/CE

4:High Intensity PCB Board

5: Customized Size and Paramete

low price 0.1w to 3w mini small solar panel

Epoxy solar panel structure

It is a traditional type small solar panel called epoxy resin encapsulated solar panel, which is sticked together by epoxy resin glue at a temperature 50~60 degree, you will see the epoxy resin coated panel have three layers,

1. Epoxy Resin AB Glue

2. Solar Cells

3. PCB Board

Features

1): Epoxy resin solar panel is made of monocrystalline or polycrystalline silicon. The encapsulation material are made of Epoxy Resin. Characterized by anti-humidity, insulation, excellent transparence and anti-aging, as well as smoothness, no bubble and neat apperance. Hard appearance; long-time life, high-performance to week light; widely used in lamp series, no power source sector.

2): Epoxy resin solar panels are easily to install; friendly environmental. High efficiency solar cells, Non-stick protective film.

3):Epoxy resin solar panels can be widely used in solar lawn lamps, solar toys, solar chargers and solar signal lights.

Epoxy Resin Solar Panel Manufacturing Process:

Cut—Assemble—Test—Epoxy Resin—Vacuumize—Bake—Inspect—Coating

Why Choose us?

Have a very strong and professional QC and selling Team

OEM Service Offered/Design Service Offered/Buyer Label Offered

Factory supplier directly

welcome to visit our factory

5.FAQ of Solar Module

1. Q: Do you have your own factory?

A: Yes, we have. Our factory located in Jiangyin city, jiangsu province.

2. Q: How can I visit your factory?

A: Before you take off from your country, please let us know. We will show you the way,or arrange time to pick you up if possible.

3. Q: Do you provide free sample?

A: Usually we do not offer free sample

4. Q: Could you print our company LOGO on the nameplate and package?

A: Yes, we can do that.

- Q:Can u guys help on how solar panels work and how it generates electricity?(or u can give me a good website that has solar panel info on it)~Thanks in advance!~

- Solar okorder under products that are sorted by watts per area. Also go to wikipedia to get more detailed information on solar cells.

- Q:I have a cabin in the woods and need more light. I do have enough sun but I was wondering how or where do I get a solar panel to lead to a power outlet? In a perfect world I would like to get a solar panel with a connecting wire to an outlet or something so I could power a small TV. I know its hard enough but can I get that pre-made? Or even lastly should I look at wind power consider I would like this to be under $500? Thank you for putting up with this bundle of questions.

- A typical solar panel will deliver 50 watts of power in the form of 24 volts DC. You need 20 volts AC. So here is what it takes: Since you will need at least 200 watts to do a small TV, you need four solar panels, and a solar controller. Then you need a 24 volt solar type battery to load the output of the panels. Next you need an inverter. This is a device that changes 24 volts DC into 20 volts AC, which you can wire to a standard outlet for the TV set. Solar panels cost around $6 per watt of power. 200 X $6 = $200 Solar Controller will cost around $50 The battery will cost around $00 The inverter will cost around $200 You could get by with less than 200 watts of solar panels if you just let it charge the battery all day and only use the TV for an hour or two in the evening with the TV running on the inverter which is powered by the battery. The link is for a similar system ready to go. Wind is not a viable option.

- Q:How do solar panels affect the electricity bill?

- Solar panels can significantly reduce or even eliminate electricity bills by generating renewable energy from the sun, thereby reducing the reliance on grid-supplied electricity. When solar panels produce more energy than is consumed, excess energy can be fed back into the grid, resulting in credits or reducing future bills through net metering programs.

- Q:How do I choose the right size of solar panels for my home?

- To choose the right size of solar panels for your home, you should consider factors such as your average electricity consumption, available roof space, and budget. Start by analyzing your energy usage over the past year to determine your average daily kilowatt-hour (kWh) consumption. Next, calculate the solar panel system size needed by dividing your average daily consumption by the average daily sunlight hours in your area. Additionally, assess your roof's orientation, shading, and structural capacity to determine the maximum number of panels it can accommodate. Finally, take your budget into account and consult with a professional solar installer to help you determine the appropriate size and type of solar panels that best meet your energy needs.

- Q:Can solar panels be installed on a gas station or convenience store?

- Yes, solar panels can be installed on a gas station or convenience store. Installing solar panels on these establishments can help offset their energy consumption and reduce their carbon footprint. Additionally, it can lead to cost savings in the long run by generating clean and renewable energy.

- Q:How do solar panels withstand hail or other weather conditions?

- Solar panels are designed to be durable and withstand various weather conditions, including hail. They are made with tempered glass that is highly resistant to impact, ensuring that hailstones won't damage the panels. Additionally, the panels undergo rigorous testing to ensure they can withstand extreme weather conditions, such as strong winds and heavy snow. The frame surrounding the panels also provides stability and protection.

- Q:Can solar panels be installed on historical or protected buildings?

- Yes, solar panels can be installed on historical or protected buildings. However, the installation process may require careful planning and consideration to preserve the building's historical integrity. This typically involves working closely with preservation experts, architects, and local authorities to find suitable installation methods that minimize visual impact and potential damage to the structure.

- Q:Can solar panels be used in commercial buildings?

- Yes, solar panels can definitely be used in commercial buildings. In fact, many businesses are increasingly installing solar panels on their rooftops or in open spaces to generate clean and renewable energy. This helps reduce their reliance on traditional grid electricity and lowers their operational costs in the long run. Additionally, commercial buildings often have ample roof space, making them ideal for maximizing solar energy generation.

- Q:China is building solar panels and have been for years. That is the most abundant energy in the world. My nieghbor has two panels on his roof and he actually sells energy back to the electric company. These panels cost about $30,000. each, because we don't produce them here on that level.If we did, that price would drop drastically. Other alternatives are also available. Drilling for oil will no change anything. Once you give the oil companie the go ahead, the will focus on that and the alternatives won't be developed any farther. We will be right back here in about 0 years. The price will not go down anyway. So why not switch half of our fuel to alternatives?

- I visit hundreds of houses a week in my line of work and there are houses in neighborhoods that aren't the wealthiest that have solar. It might be cheaper than you think.

- Q:Can solar panels be installed on south-facing windows?

- Yes, solar panels can be installed on south-facing windows. South-facing windows receive the most sunlight throughout the day, making them an ideal location for solar panel installation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Monocrystalline Silicon Solar Panel 200W Round

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords