Monocrystalline Silicon Solar Modules 110Watt

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1100 watt

- Supply Capability:

- 3000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mono-Crystalline Module, Mono 125 cell, 36pcs.Power 110W

1. Main Features of the Monocrystalline Silicon Solar Modules 110Watt Description

Specifications

broken solar panel for sale

1.Power 110Wp

2.A grade solar Cell

3.25 years Warranty

4.CE/TUV/UL

Quality and Safety

1. Rigorous quality control meets the highest international standards.

2. High-transmissivity low-iron tempered glass, strong aluminium frame.

3. Using UV-resistant silicon.

4. IS09001/14001/CE/TUV/UL

Features

1. Aesthetic appearance with excellent efficiency based on innovative photovoltaic technologies.

2. Strong frame, passing mechanical load test of 5400Pa, instead of the normal.

Warranties

1. 10 years limited product warranty

2. 15 years at 90% of the minimal rated power output

3. 25 years at 80% of the minimal rated power output

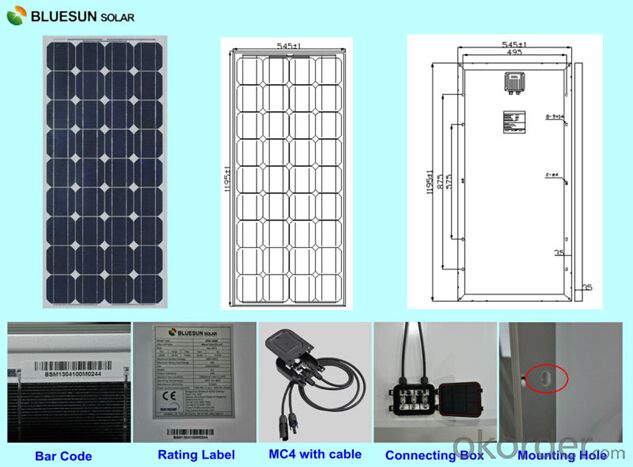

2. Detail picture of Monocrystalline Silicon Solar Modules 110Watt

3. Monocrystalline Silicon Solar Modules 110Watt Specification

ITEM NO. | Mono 125*125 cell, 36pcs. Power 110W | |||||

| Maximum Power(W) | 110 | |||||

| Optimum Power Voltage(Vmp) | 22.2 | |||||

| Optimum Operatige Current(Imp) | 4.955 | |||||

| Open Circuit Voltage(Voc) | 26.5 | |||||

| Short Circuit Current(Isc) | 5.462 | |||||

| Solar Cell: | 125*125 Mono | |||||

| Number of Cell(pcs) | 4*9 | |||||

| Brand Name of Solar Cells | JA Cell, Bluesun Cell | |||||

| Size of Module(mm) | 1195*545*35 | |||||

| Cable & Connector Type | Pass the TUV Certificate | |||||

| Frame(Material Corners,etc.) | Aluminium-alloy | |||||

| Back Sheet | TPT | |||||

| Cell Efficiency for 100W(%) | 15.80% | |||||

| Weight Per Piece(KG) | 8.8KG | |||||

| FF (%) | 70-76% | |||||

| Junction Box Type | Pass the TUV Certificate | |||||

| Tolerance Wattage(e.g.+/-5%) | 0~3% | |||||

| Front Glass Thikness(mm) | 3.2 | |||||

| Temperature Coefficients of Isc(%) | 0.04 | |||||

| Temperature Coefficients of Voc(%) | -0.38 | |||||

| Temperature Coefficients of Pm(%) | -0.47 | |||||

| Temperature Coefficients of Im(%) | 0.04 | |||||

| Temperature Coefficients of Vm(%) | -0.38 | |||||

| Temperature Range | -40°C to +85°C | |||||

| Surface Maximum Load Capacity | 2400Pa | |||||

| Allowable Hail Load | 23m/s ,7.53g | |||||

| By pass Diode Rating(A) | 12 | |||||

| Warranty | 100% of 10 years, 80% of 25 years. | |||||

| Standard Test Conditions | AM1.5 1000W/m² 25 +/-2°C | |||||

| Packing | carton or pallet | |||||

| 1*20' | 25 Pallets / 650pcs | |||||

| 1*40'STD | 50 Pallets / 1300pcs | |||||

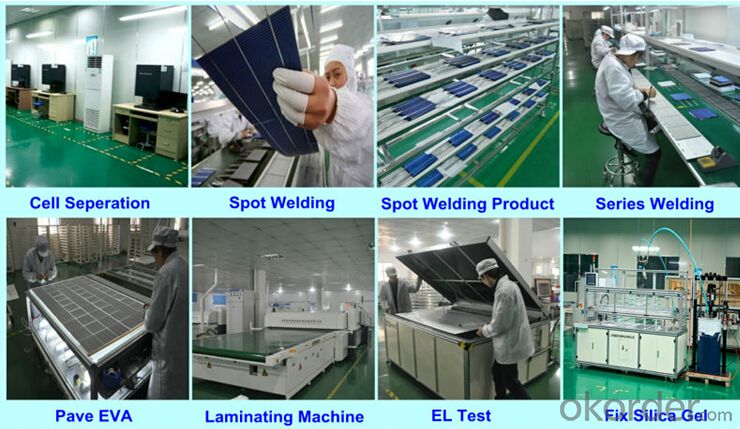

4. Standard production line of Bluesun Factory

5. Packaging & Shipping of Monocrystalline Silicon Solar Modules 110Watt

Packaging

** Normally packing: 1pc/2pcs/3pcs/10pcs/25pcs per carton

** Individual packing requirement is acceptable.

Shipping

By Sea | Delivery from Shanghai or Ningbo seaport |

| By Air | Departure from Shanghai Pudong Airport |

| By Express | Post by DHL, EMS, UPS, TNT. |

6. Certificate of Monocrystalline Silicon Solar Modules 110Watt

- Q:(For a project)I know they are made of silicon, but I want to EVERYTHING they are made of. Ex Metal (What kind)Please tell me everything used from their production to the finished projectThank you

- Well i am not sure but to my knowledge all i know is that the purpose is to save solar cells which are later created into energy Solar energy is generated from solar panels. Solar panels are slabs of semi-conductor metal. Technically speaking, they are a slab of silicon semi-conductor doped or added with impurities to make it a better conductor. Solar panels could also be made of Gallium Arsenide which is a semi-conductor metal exclusively used in photo-voltaic cells. The silicon slabs are polished and glossed before doping. After processing, for protection, a thin glass layer is embossed on the solar cells slab. Silicon also is shiny and reflects about 35% of sunlight. Hence, an anti-reflective coating is usually applied over the slabs to reduce the amount of sunlight lost. Amorphous silicon solar panels are different from the traditional ones made from silicon slabs. Amorphous silicon solar cells are thinner and more efficient that the silicon ones and also the materials cost of this variety is far lesser than the traditional. Amorphous silicon slabs are developed with superior processes which makes them less susceptible to breakage during transportation. This makes them a more viable investment when it comes to buying solar panels.

- Q:Can solar panels be used to power a military base?

- Yes, solar panels can be used to power a military base. By harnessing solar energy, military bases can reduce their dependency on traditional energy sources and enhance their operational capabilities. Solar panels can provide a reliable and sustainable source of electricity to power various facilities and equipment in a military base, contributing to energy independence and environmental sustainability.

- Q:How long does it take a 5 watt, 2 volt solar panel to charge a 2 volt R.V. battery?

- depends on the sunlight. And on the size of the battery. But it may never charge, as you need at least 5 volts to charge a 2 volt battery. So unless the sunlight is bright enough to generate 5 volts, all you will do is discharge the battery through the solar panel. But a large battery is 00 amp hours of capacity. Even if you had a 5 volt 5 watt panel, that generates only amp at most, so it would take over 00 hours to charge that size battery. .

- Q:How much energy can a solar panel generate?

- The amount of energy a solar panel can generate depends on various factors such as its size, efficiency, location, and weather conditions. On average, a standard solar panel can generate between 250 to 400 watts of electricity per hour under ideal conditions. However, it's important to note that energy production may vary throughout the day and across different seasons.

- Q:if I have a battery bank of of 6 L-6 Trojan batteries, 6V 390AH, wired in series parallel to give me 2V at 70AH (or 4,040WH) what kind of solar panels should I purchase assuming I have 8 hours of sunlight, a solar tracking system and I want to make sure I can fully recharge my batteries everyday if i use up all the power every night?i understand there are efficiency issues to consider which i have not calculated in yet. thanks.

- I don't know where you got the idea you have 8 hours of sunlight. Assuming clear skys and no dust, forest fires, clouds or other impediments, the average sunlight available in North America averages out to approx. kw/sq. meter. That's the maximum available, at midday. Multiply this be the efficiency of the cells (I assume about 0%) and it means about 00 Watts/sq m. Since you have said you have a tracking system, this works out to about 00 * .344 * 2 = 43W/h per day (per sq. meter).

- Q:what is the average cost, for a single family home, to install solar panels? I live in CA.

- Depends on the size of your home, how many appliances you want to run at one time, and how much sunlight you get because all of that determines how many panels you need and how many batteries you need to install. I checked into it earlier this year and it was going to take almost 25 years to pay for itself. They aren't cheap.

- Q:I'm making a model of a solar photovoltaic tower for a school project. I need a way to store energy, and we thought about using capacitors (mainly because of our somewhat limited funding). The tower will have a small photovoltaic panel (around the size of a laptop keyboard with number pad) and some (around 50) quot;heliostats(just the mirrors, no moving parts). What kind of capacitors should i use? and would a capacitor bank be better? i am getting confused with all those uF, pF and can't see the difference.Thanx in advance

- You need a rechargeable battery.Those uF you are talking about are Micro farads and pf are a million times smaller,they are less than gnat-bites compared to any rechargeable battery.You can get metal/metal hydride storage batteries (about .4v)and connect them in series if the voltage you generate is greater than that or in parallel if voltage is lower.Hard to advise without knowing voltage output from your design.As to getting hold of them there are so many in use you are sure to find someone who will lend a few (I would anyway!).

- Q:What is the principle and structure of solar panels?

- inverter: solar direct output are generally 12VDC, 24VDC, 48VDC. In order to provide power to 220VAC appliances, it is necessary to convert the DC power from the solar power system into AC power, so it is necessary to use DC-AC inverter.

- Q:How much electricity does a solar panel produce?

- The amount of electricity a solar panel produces depends on various factors such as its size, efficiency, location, and weather conditions. On average, a typical residential solar panel can produce anywhere between 250 to 400 watts of electricity per hour.

- Q:Can solar panels be installed on a convention center or event venue?

- Yes, solar panels can be installed on a convention center or event venue. In fact, many convention centers and event venues are increasingly adopting solar energy solutions to reduce their carbon footprint and lower energy costs. The large roof spaces available in these venues often make them ideal for solar panel installations, allowing them to generate clean and renewable energy.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Monocrystalline Silicon Solar Modules 110Watt

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1100 watt

- Supply Capability:

- 3000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords