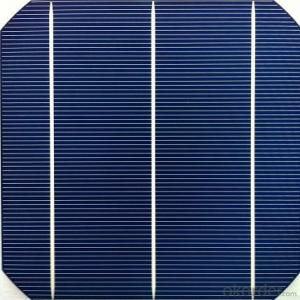

Monocrystalline Best Quality flexible solar cell with CE,ROHS,ICE Certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Model Number: | ANM250M-96 | ||||

| Material: | Monocrystalline Silicon | Size: | 1575*1082*50 | Number of Cells: | 250 |

| Max. Power: | 250 | Certificate: | CE, ROHS, ICE | Warranty: | 5 years |

| keywords: | flexible solar cell | Short circuit current(Isc): | 5.95 | Open circuit voltage(Voc): | 58.40 |

| Current at max power(Imp): | 5.28 | Voltage at max power(Vmp): | 47.33 | Max. Power (Pm): | 250 |

| Operate Temp. scope: | -40~85 | Impact Resistance: | AC2000V; DC3000V |

Packaging & Delivery

| Packaging Detail: | standard export package suitable for long seavoyage and tough handling |

| Delivery Detail: | 10-25 days depending on order quantity |

Specifications

flexible solar cell

1.Monocrystalline

2.Solar Panel Factory

3.CE, ROHS, IEC

4. 5yrs warranty

Types of Solar Cell

Current solar cells are classified into several types according to the material, structure and the manufacturing method used. Wherein the multi-crystalline silicon solar cell refers to the silicon semiconductor substrate is a monocrystalline silicon solar cells and a raw material polycrystalline silicon solar cells; in addition to amorphous silicon-based solar cells, such batteries with the liquid crystal panel prepared by the same film is based, it is deposited on a silicon substrate instead of a glass substrate made of amorphous silicon.

Monocrystalline silicon solar cells are formed on a monocrystalline silicon substrate, but also the conversion efficiency up to 20% of the products, with excellent performance and reliability characteristics. However, as the price of raw materials expensive silicon substrate, the higher cost of electricity per watt. Although polycrystalline silicon solar cell conversion efficiency is lower than that of silicon solar cells, with the advantage of cheap cost.

Most substrate monocrystalline and polycrystalline silicon solar cell used is from the slowly cooled liquefied silicon after heating the crystalline silicon block (ingot) cut out of the sheet manufacturing. Forming a polycrystalline silicon solar cell uses polycrystalline silicon ingots; forming a single crystal silicon solar cell uses single crystal silicon ingot. Compared with polysilicon ingot, single crystal silicon ingot production efficiency is lower, therefore more it is more expensive.

The more cutting thin silicon substrate, the silicon ingot obtained by the same base plate number, the more, the lower the cost. However, there are also disadvantages sheet cut easily broken during the manufacturing process. So how global materials manufacturers around the sheet during cutting and increase yield, reduce cost in a fierce competition.

Using a thin film of amorphous silicon solar cell production method is different significantly reduce the amount of silicon used, and vacuum evaporation using a manufacturing process suitable for mass production, as compared with the crystalline type can significantly reduce costs, but the amorphous silicon solar cell lower conversion efficiency is only about 10%. Such batteries silicon feedstock prices of the period of concern, but with the tight silicon market weaker than expected growth in its share.

- Q:Which brand of the solar cells is sold with the lower price on the market? Which brand is more practical for the countryside?

- SMI is a professional solar cell provider in the current market, I am sure they can provide the solar cells with low price as you expected.

- Q:Can solar cells be used in disaster relief efforts?

- Yes, solar cells can be used in disaster relief efforts. They are a reliable and sustainable source of energy that can provide electricity in areas affected by natural disasters, where power grids may be damaged or non-existent. Solar cells can be used to power emergency lighting, communication systems, medical equipment, and water purification systems, among other essential needs. Additionally, solar energy can be harnessed to charge mobile devices and provide a means of communication and access to information during these critical times. Overall, solar cells are a valuable tool in disaster relief efforts, offering a clean and renewable energy solution to support affected communities.

- Q:Can solar cells be used to power off-grid cabins or homes?

- Yes, solar cells can be used to power off-grid cabins or homes. Solar cells, also known as photovoltaic cells, convert sunlight into electricity. They can be installed on the roof or in a sunny location to capture solar energy. This energy can be stored in batteries for use during nighttime or cloudy days when there is less sunlight. With advancements in technology, solar cells have become more efficient and affordable, making them a popular choice for off-grid living.

- Q:How long do solar cells last?

- Solar cells typically last for about 25 to 30 years. However, with proper maintenance and care, they can continue to function effectively for even longer periods of time.

- Q:Can solar cells be used in cloudy or rainy weather?

- Yes, solar cells can still be used in cloudy or rainy weather, although their efficiency will be reduced. While solar cells generate less electricity under such conditions due to reduced sunlight intensity, they can still produce some power. Additionally, advancements in solar technology have improved the ability of solar cells to capture diffused and indirect sunlight, making them more viable in less optimal weather conditions.

- Q:What are the advantages of using solar cells?

- There are several advantages to using solar cells. Firstly, solar cells are a clean and renewable source of energy, which means they do not produce harmful emissions or contribute to climate change. Secondly, solar cells can be installed in remote areas without access to electricity grids, providing power to communities that would otherwise be without it. Additionally, solar cells require minimal maintenance and have a long lifespan, making them a cost-effective solution in the long run. Finally, using solar cells reduces dependence on fossil fuels, helping to conserve natural resources and promote a more sustainable future.

- Q:What is the maintenance required for solar cells?

- The maintenance required for solar cells primarily involves regular cleaning to remove any dirt, debris, or grime that may accumulate on the surface of the panels. Additionally, it is important to inspect the panels for any damage, such as cracks or loose connections, and address them promptly to ensure optimal performance. Other routine maintenance tasks include checking the inverters, monitoring the system's performance, and keeping the surrounding area free from shading objects. Overall, solar cell maintenance is relatively minimal compared to other energy sources, making it a cost-effective and sustainable choice for power generation.

- Q:Can solar cells be used for powering telecommunications towers?

- Yes, solar cells can be used for powering telecommunications towers. Solar panels can generate electricity by converting sunlight into usable energy, which can then be used to power various devices and infrastructure, including telecommunications towers. This renewable energy source provides a sustainable and environmentally friendly solution for powering such towers, especially in remote or off-grid areas.

- Q:How do solar cells perform in areas with high levels of sandstorms?

- Solar cells may not perform optimally in areas with high levels of sandstorms. The sand particles can accumulate on the surface of the solar panels, reducing their efficiency by blocking sunlight and potentially scratching the cells. Regular cleaning and maintenance would be required to ensure proper functioning of the solar cells in such conditions.

- Q:Can solar cells be used in drones?

- Yes, solar cells can be used in drones. Solar-powered drones have been developed and are being used for various applications. They use solar cells to convert sunlight into electrical energy, which can be used to power the drone's motors and other electronic components. This allows for longer flight times and reduces the need for frequent battery replacements or recharging.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Monocrystalline Best Quality flexible solar cell with CE,ROHS,ICE Certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords