Mono Solar Cells156mm*156mm in Bulk Quantity Low Price Stock 19.4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

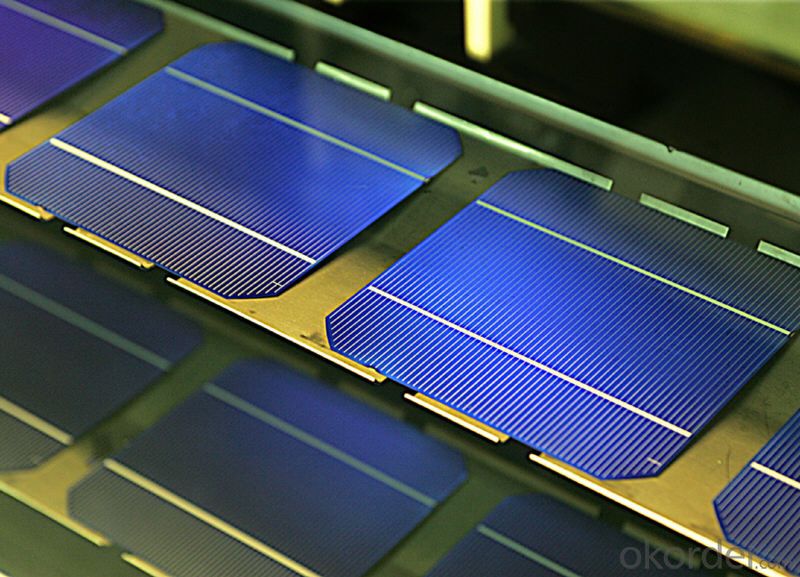

- Up to 20.0% efficiency, one of the highest performing mono crystalline cells on the market

- Three bus bars boosts current collection over the entire cell area, leading to higher fill factors

- Blue anti-reflecting coating allows more sunlight be captured and converted to electricity

- Finer, closer fingers improves charge collections for improved energy yield

- Lower light-induced degradation leads to greater power output over the entire module lifetime

- All solar cells are tightly classified to optimize output of module

- Maximum yield and longevity due to hotspot prevention

- Premium appearance results in a highly uniform and aesthetically appealing module

Specification

- Product Mono-crystalline silicon solar cell

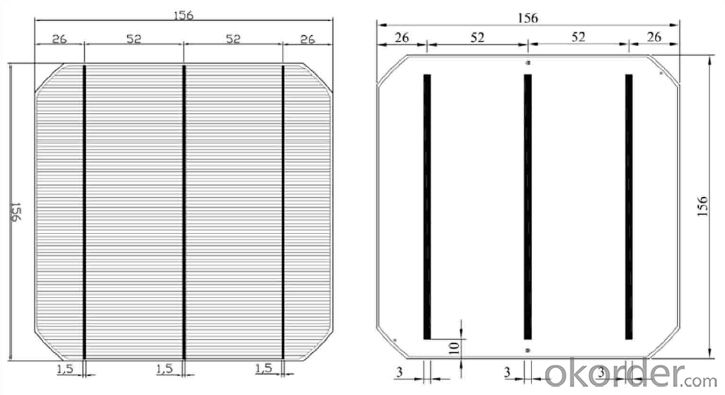

- Dimension 156 mm x 156 mm ± 0.5 mm

- Thickness 200 μm ± 30 μm

- Front 1.5 ± 0.1 mm busbar (silver)

- Silicon nitride antireflection coating

- Back 3.0 mm continuous soldering pads (silver)

- Back surface field (aluminum)

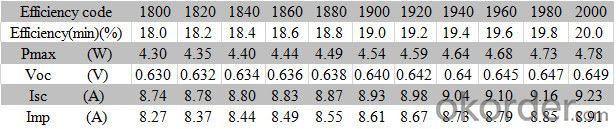

Electric performance parameters

- Testing conditions: 1000 W/m2, AM 1.5, 25 °C, Tolerance: Efficiency ± 0.2% abs., Pmpp ±1.5% rel.

- Imin : at 0.5 V

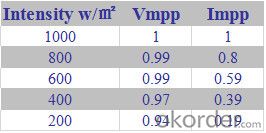

Light Intensity Dependence

Soldering Ability

- Peel Strength: > 1.0 N/mm (Pull soldered ribbon from busbar in 5 mm/s of 180°)

Dimension Figure

Quick Response

- Any time and anywhere, reply clients' email and solve all problems happen in the work at the first time.

- Remove clients doubts and offer the best solution at the first time.

- Give our clients the lastest news of the photovoltaic, update the newest stock informtion.

Production and Quality Control

- Precision cell efficiency sorting procedures

- Stringent criteria for color uniformity and appearance

- Reverse current and shunt resistance screening

- ISO9001,ISO14001 and OHSAS 18001,TUV Certificated

FAQ:

1. Q: Do you have your own factory?

A: Yes, we have. Our factory located in Jiangsu

2. Q: How can I visit your factory?

A: Before you visit,please contact us.We will show you the route or arrange a car to pick you up.

3. Q: Do you provide free sample?

A: Commenly we provide paid sample.

4. Q: Could you print our company LOGO on the nameplate and package?

A: Yes, we accept it.And need an Authorization Letter from you.

5. Q: Do you accept custom design on size?

A: Yes, if the size is reasonable.

6. Q: How can I be your agent in my country?

A: Please leave feedback. It's better for us to talk about details by email.

7. Q: Do you have solar project engineer who can guide me to install system?

A: Yes, we have a professional engineer team. They can teach you how to install a solar system.

- Q:What are the different types of glass covers used on solar silicon wafers?

- The different types of glass covers used on solar silicon wafers include tempered glass, anti-reflective coated glass, textured glass, and transparent conductive oxide coated glass.

- Q:How do solar silicon wafers perform in humid environments?

- Solar silicon wafers perform well in humid environments as they are typically designed to withstand moisture and humidity. The silicon material used in these wafers is non-reactive to water, preventing any significant degradation or damage. Additionally, modern solar panels are encapsulated with materials that provide excellent protection against moisture, ensuring their long-term performance and durability even in humid conditions.

- Q:How do solar silicon wafers perform in extreme weather conditions?

- Solar silicon wafers are designed to withstand extreme weather conditions effectively. They are typically made from durable materials that can handle temperature variations, such as high heat or freezing cold. Additionally, they are designed to be resistant to moisture, wind, and hail, ensuring their performance remains stable even during storms or extreme weather events. However, it is important to note that extreme weather conditions can still have some impact on the overall efficiency of solar panels, reducing their energy production temporarily.

- Q:How does the thickness of a passivation layer affect the efficiency of a solar silicon wafer?

- The thickness of a passivation layer significantly affects the efficiency of a solar silicon wafer. A thicker passivation layer creates a stronger barrier between the silicon wafer and the surrounding environment, reducing surface recombination and enhancing charge carrier lifetime. This results in higher overall efficiency of the solar cell as it allows for more effective utilization of the incident sunlight. However, there is an optimal thickness range for the passivation layer, as an excessively thick layer can introduce additional surface defects, leading to decreased efficiency.

- Q:How do solar silicon wafers perform in dusty and sandy environments?

- Solar silicon wafers can perform well in dusty and sandy environments, although the presence of dust and sand can impact their performance to some extent. The accumulation of dust and sand particles on the surface of solar panels can reduce the amount of sunlight reaching the silicon wafers, resulting in lower energy production. To mitigate this, regular cleaning of the panels is necessary to maintain optimal performance. Additionally, advancements in panel design and coatings have been made to minimize the impact of dust and sand, ensuring better performance in such environments.

- Q:What is the role of a solar silicon wafer in a solar cell?

- The role of a solar silicon wafer in a solar cell is to serve as the substrate or base material where the photovoltaic process takes place. The silicon wafer is typically doped with impurities to create a p-n junction, which allows for the conversion of sunlight into electricity. It acts as the main absorber of light, generating electron-hole pairs when photons hit its surface. These electron-hole pairs are then separated and directed by the electric field within the solar cell, ultimately producing an electric current.

- Q:Can solar silicon wafers be used in agricultural applications?

- Yes, solar silicon wafers can be used in certain agricultural applications. They can be integrated into solar panels to power irrigation systems, electric fences, and other farm equipment. Additionally, solar-powered sensors and monitoring systems can be developed using silicon wafers to optimize crop growth and monitor environmental conditions in agricultural settings.

- Q:How are solar silicon wafers protected from electromagnetic interference?

- Solar silicon wafers are protected from electromagnetic interference through the use of specialized materials and shielding techniques. One common method involves encapsulating the wafers in a protective layer of non-conductive material, such as glass or plastic, which acts as a barrier against electromagnetic waves. Additionally, the solar cells are often housed within a metal frame or casing that further enhances the shielding effect. This combination of materials and design helps to minimize the impact of electromagnetic interference on the performance and efficiency of solar silicon wafers.

- Q:How are solar silicon wafers protected from transportation damage?

- Solar silicon wafers are typically protected from transportation damage through various packaging methods. They are often placed between foam sheets or cushioned with protective materials to prevent any physical impact during transit. Additionally, they may be packaged in sturdy boxes or crates, ensuring that they are securely held in place and protected from any potential breakage or damage caused by external forces.

- Q:How are solar silicon wafers affected by temperature-induced stress?

- Solar silicon wafers are affected by temperature-induced stress in several ways. Firstly, as the temperature increases, the thermal expansion of the silicon material causes it to expand, leading to mechanical stress on the wafer. This stress can result in warping or even cracking of the wafer. Secondly, temperature fluctuations can cause differential expansion and contraction across different layers of the wafer, especially if it is a multi-layered structure. This can lead to delamination or detachment of layers, compromising the integrity and performance of the wafer. Thirdly, temperature-induced stress can affect the electrical properties of the silicon material. Increased stress can alter the bandgap and carrier mobility, potentially impacting the efficiency of the solar cell. Overall, it is crucial to carefully manage temperature-induced stress in solar silicon wafers to ensure their structural integrity and optimal performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mono Solar Cells156mm*156mm in Bulk Quantity Low Price Stock 19.4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords