Mono panel JAM5(R) 72 210W

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

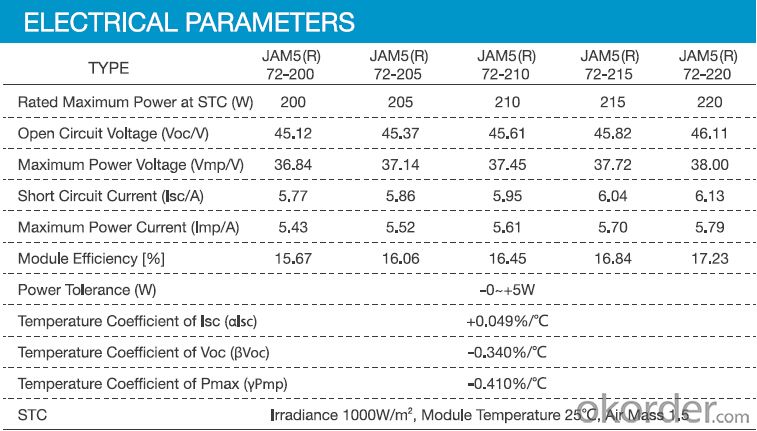

JAM5(R)72 200-220W FULL SQUARE MONOCRYSTALLINE SILICON MODULE

Key futures:

Full square monocrystalline modules designed for residential,commercial and utility applications as well as rooftop or groud mount.

high power output and highest conversion effciency of 16.84%

Anti-reflective and anti-soiling surface reduces power loss from dirt and dust;

outstanding prformance in low-light irradiance environments;

excellent mechanical load resistance:certified to wothstand high wind loads (2400pa)and snow loads(5400pa)

high salt and ammonia resistance certified by TUV NORD

Datasheet:

- Q:how to make electricty using solar panels or wind generator

- Hey Bandit, there are some really good websites on the subject, my favorites are operated by non profit groups, I will list them below. As the old saying goes, the best things in life are free, but there is one really good exception to that rule. Home Power Magazine is the only periodical that gets into the nuts and bolts of home grown energy. We started reading it 2 years ago. A couple years after that we attended an energy fair that was listed in the magazine, ended up buying our first solar panel and wind turbine on the spot, and hooking up a small 2 volt power system for our home that year. It worked really well, we did make some mistakes, but with the knowledge and experience we gained, we were able to get into a larger system a few years later. Now our home generates almost all its own power, and we use the utility company for backup. There is a .4 kw solar array on the garage roof, and a kw turbine on a metal tower in the field behind the house. We have also installed a batch solar water preheater and have 2 wood stoves for heat. Now our electric bills are around $6 per month. If your handy at all hooking up electrical devices, you could put together a small system like we did years ago and use it to run some small 2 volt lights and electronics. We still have our little system today, it operates the cabinet lighting in the kitchen, a few radios and phone answering machine, and we have 2 volt outlets in each room. They're handy for stuff like charging your cell phone with a car cord. I would suggest looking at the websites first, and if you're really interested, go for a one year subscription to Home Power. If you subscribe, you can even use their website to look at archived articles from years past. There is even one on our small system, the magazine liked the idea so much they wrote it up. Use their search engine to look for, Small System First. Hope you find all this interesting. Take care Bandit, Rudydoo

- Q:I have some property off the grid and am looking to add solar power

- Most Solar Panels are roughtly 6% efficient. Since the sun gives out about 366 watts per square meter, a good panel would be 200+ W/square meter. If you want to save a bunch of money, I suggest you have a look at this tutorial I'm linking. The guy explains how you can assemble your panel yourself. It's far easier than I first thought !

- Q:How do solar panels affect the aesthetics of a roof?

- Solar panels can have both positive and negative effects on the aesthetics of a roof. On one hand, the sleek and modern design of solar panels can enhance the overall appearance of a roof, giving it a more futuristic and eco-friendly look. On the other hand, the presence of solar panels can be seen as an obstruction or deviation from the traditional appearance of a roof, which some individuals may find unappealing. Ultimately, the impact on aesthetics will depend on personal preference and the integration of solar panels into the overall design of the building.

- Q:I want to purchase some or one solar panel for my home. I don't know where to buy them from. I've loooked online and if i could buy them online that would be best, but if you knew of a website that has good prices than that would be great!Thanks

- I okorder Hope this helps.

- Q:Can solar panels be used in areas with high levels of hurricanes?

- Yes, solar panels can be used in areas with high levels of hurricanes. However, it is important to ensure that the solar panels are designed and installed to withstand strong winds and other extreme weather conditions. Proper mounting and anchoring techniques, along with robust construction materials, can increase the resilience of solar panels against hurricanes. Additionally, regular inspections and maintenance are necessary to ensure their functionality and safety in such areas.

- Q:Can solar panels be installed on a prison or correctional facility?

- Yes, solar panels can be installed on a prison or correctional facility. Installing solar panels can help reduce the facility's reliance on traditional energy sources and lower its carbon footprint. Additionally, it can save money on electricity costs in the long run. However, there may be certain security considerations and regulations that need to be addressed to ensure the panels do not pose any risks or vulnerabilities.

- Q:I am in need of solar panels and the batteries that I can store the energy in. I need to be able to run a laptop, cell phone, and LED lights from it. When I research I see all sorts of options with regards to watts, VMPs, and AMPs. I also see that I may need a controller, an inverter, and various other components. Can anyone help me through these terms and what i need to know in order to efficiently generate and store the electricity. Thanks

- Unlike what most people seem to think, solar panels are not advanced enough to power day to day objects that we use, with the sun that we see in a day. You would need mass amounts of panels and equipment. IF there is a smaller solutions (which I doubt would do what you're asking yet) it would cost thousands of dollars. Panels are not there yet, and the ones that are, are still in development or being guarded from release to the public. The most you'll get out of a few hundred bucks and panels is a lit garden for a few hours at night. Go buy rechargeable batteries.

- Q:Hi! I bought a Coleman 2 vdc cooler that pulls 9 amps. What size solar panel and amp-hour battery do I need? I only open it 3 times a day. It will hold about 3 gals of milk.

- If it pulls 9 amps continuously, that's 08 watts/hour or about 2.5 kwh/day. If it only pulls half that (does it cycle?) it's about .2 kwh/day. You only want to drain a lead-acid battery 50% or so, so you'll want a 5 or 2.5 kwh battery pack. A typical setup for the 5 kwh would be two L-6 batteries in series, and for the 2.5 kwh you could use 2 T-05 batteries in series. This does not account for days of cloud. If you regularly have cloudy days, size the battery pack for two or three days of use with no input (2-3 x the sizes given above). To charge them, you typically want panels that will charge your battery at least 5% of its capacity per hour (C/20). For 2 volt nominal panels that's 0 amps for the T-05 or 20 amps for the L-6 batteries. It's good to have more than that for battery life (it cuts down on what's called stratification), so you'll want probably 50-200 watts of panels for the T-05 and 300-400 for the L-6. You'll also need a charge controller. Peltier coolers are very inefficient. You'll save money by using a regular mini-fridge and an inverter. Most mini-fridges only draw 50 watts or so, so you're talking 600 watt-hours for a 50% duty cycle. This means two T-05 batteries will give you two days of use and you'll only need 20-50 watts of panel. DK

- Q:Would like to know if the DIY Solar panel systems can be as efficient as a commercial grade panel.

- Create okorder

- Q:I would like to know of any construction companies, road crews, or any company that uses solar panels in the Tampa area and throws them away. I like to recycle solar panels by repairing and processing what power I can from them. Know any companies that throw out used solar panels? If so, can you provide the name and number?

- When you pass a sign- look at the back of it for a name. Often the company that rented them out will have their name on the back. Call them.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mono panel JAM5(R) 72 210W

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords