Modified Asphalt Waterproofing Self-adhesive Roofing Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications Modified Asphalt Waterproofing Self-adhesive Roofing Membrane:

Introduction:

SBS(Styrene Butadiene Styrene) /APP (Atactic Polypropylene) modified bitumen membrane is made by saturating the base in bitumen, or thermoplastic elastomer (such as SBS, APP, APAO, APO), reinforced with polyester or fiberglass, finishing the upward face with polythene membrane, fine sands or mineral slates (or grains) or etc.

Specification Modified Asphalt Waterproofing Self-adhesive Roofing Membrane:

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Applications Modified Asphalt Waterproofing Self-adhesive Roofing Membrane:

-Roof and underground in industrial and civil buildings;

-Bridge, subway, tunnel, swimming pool, etc.

-Waste landfill, sewage plant, irrigation system, etc.

-Self-adhesive Modified Bitumen Waterproof Membrane

-Easy applying and economic on the cost saving

Advantage Modified Asphalt Waterproofing Self-adhesive Roofing Membrane:

-Non-solidified, excellent elastic deformation,thus have good noise reducing;

-Easy applying and economic on the cost saving.

-Good performance on waterproof and economic sound damping.

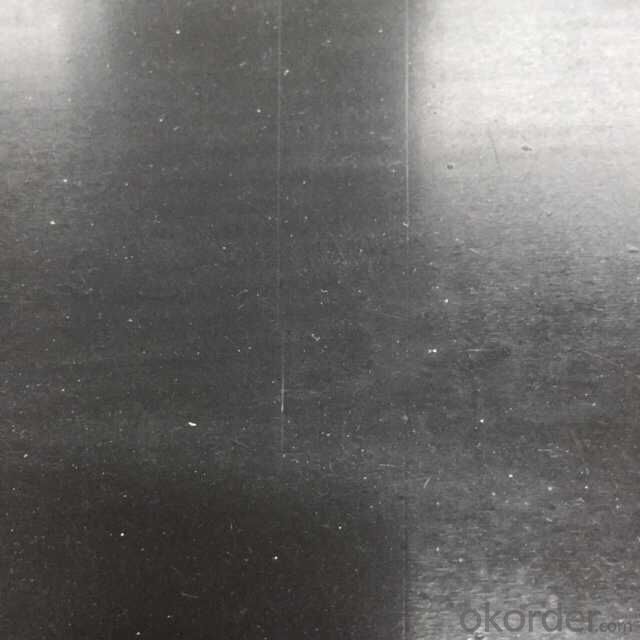

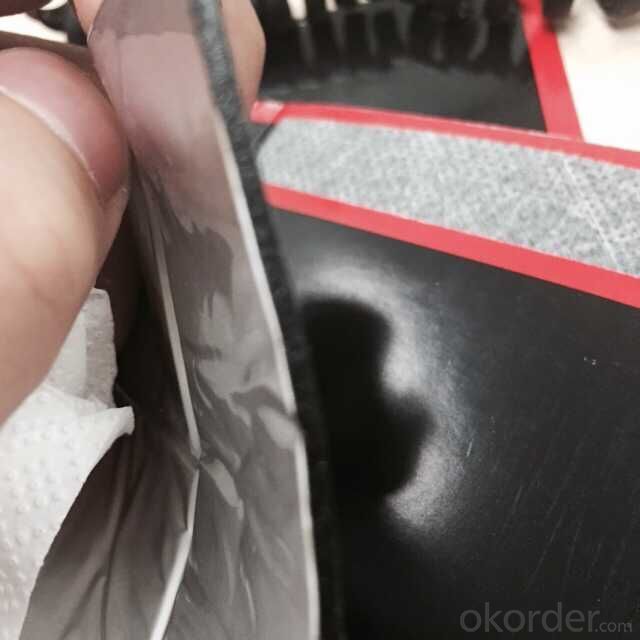

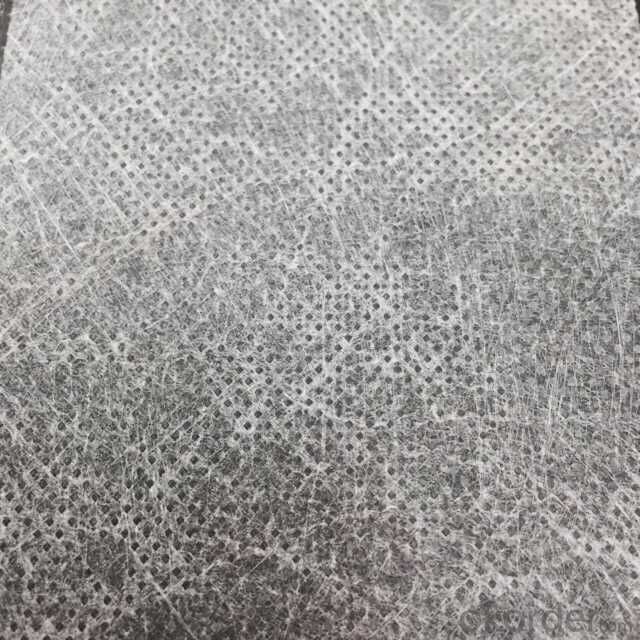

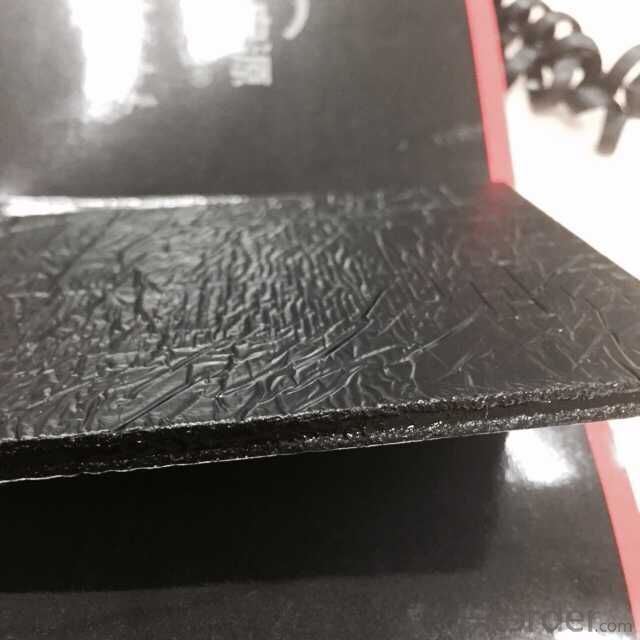

Picture Modified Asphalt Waterproofing Self-adhesive Roofing Membrane:

Storage:

Shelf life is 12 months. Store in a cool and dry place with original packing.

Breathable Waterproof Roof Underlay membrane (PP-PP,S-PP,S-S)

Permeable membrane is polymer modified asphalt based, with surface of high strength polypropylene fiber. Back side coated with self adhesive glue or antiskid sand. Made by special process. With excellent waterproof performance and breathable properties.\

Description | Specification | Width | Length | Thickness | |

Roof underlay | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

Roof underlay with adhesive band | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

It is used as the underlayment of cement tile, painted pottery watts and asphalt shingle. Also suitable for all kinds of architectural roofing, walls, underground waterproof and damp proof project.

Features:

It has good waterproofing and ageing-resistance function,not flowing at highest temperature and no crack at lowest temperature;

Easy application,no pollution,and long service life etc.

Usage:

It is widely used for industry and civil building --- the waterproof and dampproof of the roofs,basements,toilets etc;and the waterproofing of bridges,parking area,tunnels,reserviors etc.

It is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions.

Requirements for surroundings

-The base should be dry and clean. Do not work in the rainy or snowy day.

-Do not work under heavy wind(above 5 grade)

-Unsuitable for construction below 0°C

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:Are there any drawbacks or limitations to using a waterproofing membrane?

- Using a waterproofing membrane comes with its fair share of drawbacks and limitations. One issue is the time-consuming and labor-intensive installation process. These membranes require careful surface preparation and multiple layers, which can be both time-consuming and require skilled labor. As a result, the overall cost of the project may increase. Another limitation is that not all surfaces are suitable for waterproofing membranes. Certain membranes are designed for specific types of substrates, such as concrete or metal, and may not adhere properly to other materials. To ensure proper adhesion and effectiveness, it is crucial to select the appropriate type of membrane for the specific surface. Moreover, waterproofing membranes can be sensitive to environmental conditions. Exposure to extreme temperature fluctuations, UV rays, and chemicals can degrade the membrane over time, reducing its effectiveness. To ensure the longevity of the membrane, regular inspections and maintenance may be necessary. Furthermore, during installation or due to external factors such as foot traffic or heavy objects, waterproofing membranes can be susceptible to damage. Punctures, tears, or improper installation can compromise the integrity of the membrane and reduce its ability to prevent water infiltration. Lastly, in certain situations, waterproofing membranes may not completely prevent water penetration. If there are existing cracks or structural issues in the substrate, water may find a way to seep through, bypassing the membrane. Therefore, it is important to address any underlying structural issues before applying the membrane to ensure optimal performance. In conclusion, while waterproofing membranes offer significant benefits in terms of water damage protection, it is crucial to consider these limitations and drawbacks before deciding to use them in specific applications.

- Q:Can a waterproofing membrane be used on precast nickel surfaces?

- Precast nickel surfaces can indeed benefit from the application of a waterproofing membrane. These membranes are specifically designed to create a barrier against moisture and thwart water infiltration. They can be effectively utilized on a variety of surfaces, such as concrete, metal, and even nickel. Nevertheless, it is crucial to ascertain that the waterproofing membrane is appropriate for use on nickel surfaces and is compatible with the particular type of precast nickel in question. To obtain guidance on the specific application and guarantee proper adhesion and effectiveness of the membrane on precast nickel surfaces, it is advisable to consult a professional waterproofing contractor or reach out to the manufacturer of the membrane.

- Q:Can a waterproofing membrane be used on crawl spaces?

- Yes, a waterproofing membrane can be used on crawl spaces. It can effectively prevent moisture from seeping into the crawl space, protecting it from water damage and potential mold or mildew growth.

- Q:Can a waterproofing membrane be used in renovation or retrofitting projects?

- Certainly, a waterproofing membrane is a viable option for use in renovation or retrofitting endeavors. In fact, it often plays a crucial role in these projects, guaranteeing the long-term resilience and safeguarding of the building or structure. Waterproofing membranes are specifically designed to establish a barrier against moisture infiltration, effectively thwarting water damage, mold proliferation, and structural decay. When engaging in renovation or retrofitting tasks, it is not uncommon to encounter predicaments such as leaks, cracks, or deteriorated building materials that undermine the building's waterproofing system. In such scenarios, the application of a waterproofing membrane over the affected areas proves to be a reliable method of sealing and protecting them from further harm. This can be accomplished both internally and externally, tailored to the specific requirements at hand. Waterproofing membranes are available in a variety of forms, including sheet membranes, liquid coatings, or spray-applied membranes. They can be employed on various surfaces such as roofs, walls, basements, and even foundations. These membranes possess qualities such as flexibility, durability, and resistance to water and other environmental pressures, rendering them exceptional for renovation or retrofitting undertakings where augmenting the building's waterproofing capabilities is imperative. In conclusion, it is highly advisable to incorporate a waterproofing membrane into renovation or retrofitting ventures to ensure the endurance and integrity of the building. It serves as a proactive measure to preclude future water damage, preserve structural stability, and enhance the overall quality of the revitalized or retrofitted space.

- Q:Can a waterproofing membrane be used for a balcony?

- Yes, a waterproofing membrane can be used for a balcony. A waterproofing membrane is designed to prevent water penetration and protect surfaces from moisture damage. Balconies are exposed to the elements and are prone to water damage, so applying a waterproofing membrane is essential to extend their lifespan and maintain their structural integrity. The membrane is applied to the balcony surface, creating a barrier that prevents water from seeping through cracks or joints. This helps to prevent water damage, such as leaks, mold, and deterioration of structural elements. It is important to select a high-quality waterproofing membrane that is suitable for outdoor use and can withstand exposure to UV rays, temperature changes, and foot traffic. A professional contractor should be consulted to ensure proper installation and to choose the right waterproofing system for your specific balcony needs.

- Q:Can a waterproofing membrane be used in renovation or retrofitting projects?

- Certainly, a waterproofing membrane is a viable option for use in renovation or retrofitting endeavors. In fact, it often plays a crucial role in these projects, guaranteeing the long-term resilience and safeguarding of the building or structure. Waterproofing membranes are specifically designed to establish a barrier against moisture infiltration, effectively thwarting water damage, mold proliferation, and structural decay. When engaging in renovation or retrofitting tasks, it is not uncommon to encounter predicaments such as leaks, cracks, or deteriorated building materials that undermine the building's waterproofing system. In such scenarios, the application of a waterproofing membrane over the affected areas proves to be a reliable method of sealing and protecting them from further harm. This can be accomplished both internally and externally, tailored to the specific requirements at hand. Waterproofing membranes are available in a variety of forms, including sheet membranes, liquid coatings, or spray-applied membranes. They can be employed on various surfaces such as roofs, walls, basements, and even foundations. These membranes possess qualities such as flexibility, durability, and resistance to water and other environmental pressures, rendering them exceptional for renovation or retrofitting undertakings where augmenting the building's waterproofing capabilities is imperative. In conclusion, it is highly advisable to incorporate a waterproofing membrane into renovation or retrofitting ventures to ensure the endurance and integrity of the building. It serves as a proactive measure to preclude future water damage, preserve structural stability, and enhance the overall quality of the revitalized or retrofitted space.

- Q:Can a waterproofing membrane be used on insulation surfaces?

- Yes, a waterproofing membrane can be used on insulation surfaces. In fact, it is often recommended to install a waterproofing membrane over insulation to provide an additional layer of protection against water infiltration. This is especially important in areas where moisture is a concern, such as basements, roofs, or exterior walls. The waterproofing membrane acts as a barrier, preventing water from seeping into the insulation and causing damage. It also helps to maintain the integrity and effectiveness of the insulation by keeping it dry. Additionally, some waterproofing membranes have the added benefit of improving the energy efficiency of the insulation by reducing air leakage and heat transfer. Overall, using a waterproofing membrane on insulation surfaces is a smart and practical solution to protect your building or home from water damage.

- Q:Can a waterproofing membrane be used for swimming pool decks and patios?

- Yes, a waterproofing membrane can be used for swimming pool decks and patios. A waterproofing membrane is designed to prevent water penetration and protect the underlying structure from water damage. Swimming pool decks and patios are constantly exposed to water, whether through splashing or rain, making them susceptible to water damage. By applying a waterproofing membrane, you can ensure that the pool deck or patio remains protected and free from water-related issues such as cracking, mold, or deterioration. This membrane acts as a barrier, preventing water from seeping into the concrete or other materials, thus extending the lifespan of the pool deck or patio. It is essential to choose a high-quality and suitable waterproofing membrane specifically designed for outdoor use to ensure optimal performance and durability.

- Q:Are waterproofing membranes resistant to saltwater?

- Yes, waterproofing membranes are generally resistant to saltwater. They are designed to provide a barrier against water penetration, including saltwater, and are commonly used in applications where exposure to saltwater or other corrosive environments is expected.

- Q:Are waterproofing membranes resistant to chlorine exposure?

- Yes, waterproofing membranes are typically resistant to chlorine exposure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Modified Asphalt Waterproofing Self-adhesive Roofing Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords