Model D2500-120 Tower Crane with Good Vision and Large Inner Space Cab

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Performance parameters of D2500-120: performance parameters and technical indexes reach both domestic and international advanced level.

• Max. jib length: 70m; Jib length under different assembling modes can decrease progressively by 10 meters and the Min. jib length is 40 meters.

• Maximum lifting capacity 42t;

• Max. hoisting capacity at jib tip: 59.3t;

• Maximum lifting moment 25000 t.m;

• Max. free-standing height: 103m; Max. working height of anchored crane: 250m;

• Hoisting mechanism: Q110P150; power: 2×110 kW; rope capacity: 2×580m;

• Slewing mechanism: HP185F1.350/ HP185F2.350; power: 4×18.5 kW (80m Jib); 3×18.5 kW(others).

• Trolleying mechanism: BPI185; power: 18.5 kW.

2. Electrical control system

With PLC control, the electrical control system enjoys better reliability and safety. Produced by professional manufacturers with advanced foreign technology, the electrical elements feature service lives that are 3 or 4 times longer than that of domestic products, less faults, easy maintenance and repair as well as reliable operation.

3. Technical features

• The crane boasts of multiple operation modes and wide application;

• The complete machine adopts internationally well-received beautiful shape;

• The crane features high working speed and excellent speed regulation performance. Stepless speed regulation by frequency control, the world's most advanced solution, is adopted for the trolleying mechanism and slewing mechanism, thus ensuring more stable and reliable operation ;

• The cab is independently installed externally with good vision and large inner space, thus offering a good working environment for operators;

• A variety of safety devices are equipped, which are all mechanical or mechatronic products that are applicable to severe working conditions, so as to ensure the tower crane's reliable operation.

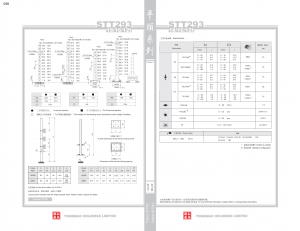

4 Parameters:

Rated hoisting moment (kN.m) | 25000 | |||||

Lifting height (m) | Free-standing stationary crane | Anchored crane | ||||

103 | 220 | |||||

Working radius (m) | Max. working radius | 70 | ||||

Min. working radius | 7.5 | |||||

Max. lifting capacity (t) | 120 | |||||

Hoisting mechanism | Rope fall | α=4 | α=8 | |||

Speed (m/min) | 45 | 18 | 18 | 9 | ||

Lifting weight (t) | 10 | 60 | 55 | 120 | ||

Power (kW) | 2×110 | |||||

Traction mechanism | Speed (m/min) | 0~40 | ||||

Power (kW) | 18.5 | |||||

Slewing mechanism | Speed (r/min) | 0~0.55 | ||||

Power (kW) | 18.5×4/18.5×3 | |||||

5 Images:

6 FAQ :Installation of hoisting mechanism

Hoisting mechanism adopts single motors and big diameter reel, also equipped with normal closed braket and limit switch.which developed hoisting mechanism work efficiency and steel wire life greatly. Steel wire type: 14NAT6×37s+FC1670ZS93.1.Rope capacity of reel: 340m. The mechanism was fixed at middle and rear part of counter-jib by 4 pins.

Fix hoisting mechanism on counter jib by 4 Φ25×49 pins and 4Φ6×40 cotter pins.

- Q:?? Please star my ? i will give you points!

- Although I haven't seen it done I imagine that especially for very high cranes it's done most often with cables and winches (utilizing a pivot point at the bottom of the structure). For many lower cranes such as those found on vehicles hydraulic lifting is sufficient.

- Q:I know how to make cranes and I'm pretty fast at doing so but in pictures I see of crane leis the cranes look like they're folded differently so that they can be stacked on top of each other.. Can anyone teach me how to fold like that so that I can make a paper crane lei?

- But I do different from step 11 on Step 11: Normally they fold along the red line. I dont. On step 10 you see the cross line in the center +. I then fold the right pointy toward the center. Do the same for all. Step 12: I the filp the right top layer to the left, same with the back side. Step 13: fold the bottom point to the top(one layer only) filp to back side, do the same. Step 14: flip right layer to the left again, same with the back side. Step 15: Pull and done.

- Q:Where can I buy Crane Lake wine in Orange County?

- I'm looking for them too

- Q:any1??

- forces for cranes are dynamic , so u'll have repeated cycles of compression tension ( i assume it's a trussed crane). but generaly for a cantilever , the main forces are -ve Bending Moment +ve shear which changes the rft. bars position if dealing with R.Concrete for example

- Q:expane the parts of crane?

- The spelling error is fatal: expane does not resemble anything that makes sense. At least two things are called a crane, one a machine and the other a bird. So you just need to rewrite your question so that it explains what you want clearly enough for somebody to look up an answer.

- Q:The arm of a crane at a construction site is 12.1 m long, and it makes an angle of 30° with the horizontal. Assume that the maximum load the crane can handle is limited by the amount of torque the load produces at the base of the arm. (a) What is the magnitude of the maximum torque the crane can withstand if the maximum load the crane can handle is 500 N?(b) What is the maximum load for this crane at an angle of 35° with the horizontal?

- (a) What is the magnitude of the maximum torque the crane can withstand if the maximum load the crane can handle is 500 N? τ = FL τ = 500(12.1cos30) τ = 5239.45 τ = 5240 Ν?m (b) What is the maximum load for this crane at an angle of 35° with the horizontal? τ = FL F = τ / L F = 5239.45 / 12.1cos35 F = 528.6109... F = 529 N I hope this helped. Please remember to vote a Best Answer from among your results. It's good karma as it keeps things in balanced exchange.

- Q:What are the common problems encountered in hiring cranes for house constructions?

- Access, I assume you need a Franna. Possibly for frames and or trusses to the second level or steel beams. You will be limited by reach if the crane can only access the front of the house. In which case you may need a slew crane 30t or larger. Know the weights of what has to be lifted and the distance from the crane to where it will be placed. A crane cannot set up or travel over underground services or recently filled excavation. These things could mean the crane has to set up even further away from the house. If the crane is for unloading trucks, access again. Cranes need to stay about 3meters from power lines which is a common problem bringing gear onto site. While a slew crane generally sets up in one position for all lifts (some can travel) a Franna is designed specifically for pick and carry. It can unload trucks and travel the gear onto site under the power lines. Provided it isn't lifting extra large items. Speak with the provider about what has to be done, it will be all to familiar for any decent company. As long as access is fine and underground services won't hinder you they should know exactly what you need. Be prepared, usually a minimum 4hr hire. If you think the task is going to take longer you need to plan what has to be done and have everything ready for placement. Organization is paramount, you don't want a crane and it's crew sitting there doing nothing because you didn't plan ahead. Hope this helps, I could have been more specific if the question had some details.

- Q:This is a new technology in ringging work. Hope anyone can give me some detail information about wireless crane scale.

- Hi, okorder for more information

- Q:Why do you think children all over the world still fold paper cranes and send them to Hiroshima? Please answer c:

- I think she died.

- Q:What is a TQ80 tower crane?

- The concrete transport vehicle can be used at the lower part of the tower of the large tower crane. The one we usually see at the construction site is.) TQ80 is a model of cranes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Model D2500-120 Tower Crane with Good Vision and Large Inner Space Cab

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords