MODEIFED SILICON PREPAINTED ALUZINC STEEL COIL FOR PRODUCTION ROOM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

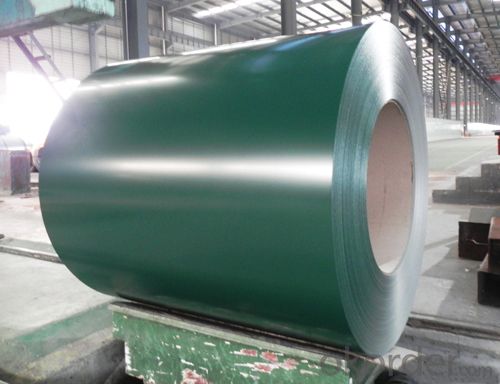

1.Structure of Pre-painted Galvanized Steel Description:

With GI as base metal, after pretreatment and liquid dope with several layers of color, then after firing and cooling, finally the late steel is called pre-painted galvanized steel which is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3. Pre-painted Galvanized Steel Images

4. Pre-painted Galvanized Steel Specification

Standard: JIS G3312 ASTM 755M, EN10169

Grade: CGCC,CS, DX51D

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How clients can follow up the order procedure?

We have effective ETP working systerm and opened okorder-in service for every client.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q:What are the CTP plates?

- Photopolymerized media This type of plate is usually made of aluminum, photosensitive layer and surface layer. The photopolymerizable layer is mainly composed of a polymerized monomer (+ oligomer), an initiator, a spectral sensitizer and a film-forming resin. The initiator is widely used as a multi-initiator system with high quantum efficiency. The effect of the spectral sensitizer is to effectively extend the range of the initiator to the luminescence wavelength region of the laser. It can now extend to 488nm (ion laser) and 532nm ( Multiplied YAG laser). The role of the surface layer is mainly the atmosphere of oxygen molecules separated, to avoid its into the photosensitive layer, in order to improve the photosensitive layer of the chain growth efficiency, resulting in high sensitivity. As a result of these effective measures, the photopolymerization of the direct plate of the sensitivity has been greatly improved, the minimum imaging exposure has dropped to about 10μJ / cm2, second only to the silver salt type of direct plate, and this plate structure Simple, resolution, printing rate and post-processing and conventional PS version similar or even better. Since the range of intrinsic photoreactivity of most efficient initiator systems is in the ultraviolet region and the photometric range extends to the range of the emission wavelength of the UV-LD laser, the photopolymerized direct plate will become the next generation of UV direct Preferred system, has a very good development prospects.

- Q:What are the environmental ratings of the board?

- Hello there! Now the quality of the sheet can be divided into E2 class E1 level E0 level. EO grade formaldehyde emission is the lowest, E2 grade formaldehyde emission is the highest. According to the January 1 this year, the implementation of the "interior decoration materials, wood-based panels and their products in the formaldehyde release limit" requirements, direct use of indoor building materials, formaldehyde emission must be less than or equal to 1.5 mg per liter, if formaldehyde release The amount of less than or equal to 5 mg per liter, it must be treated after finishing to indoors, formaldehyde emission exceeds 5 mg per liter is substandard. The unqualified timber to take home like a new home to add a poison gas machine, buy building materials must first look at environmental protection is not environmentally friendly. Currently on the market brands are: dew river, bunny, Moganshan series Kyushu wood and so on.

- Q:What kind of sheet is more environmentally friendly?

- Norby forest plate are more environmentally friendly E1 level is the formaldehyde emission is 1:00, E0 level is 0:00, of course, E0 level more environmentally friendly

- Q:On the difference between Q235 and Q345 plate and use

- Q235 steel is an ordinary carbon structural steel, that the old A3 steel its yield point is 235MPa, tensile strength of 375-500MPa. General use more. Q345 steel is a low-alloy high-strength structural steel, including 16Mn, 12MnV, 14MnNb, 18Nb, 16MnRe, including a class of steel, the yield point of 345MPa, tensile strength of 470-630MPa. Ordinary quality of low alloy steel.

- Q:Matt sheet and high light plate difference

- My home is to use a paint-free board, its surface is a layer of broadcast film, a kind of plastic things, the surface of the speaker useful to this material, this panel is easy to be painted, and can not repair, it is thin, bad. But not easy to deformation, and no paint, no paint taste, relatively environmentally friendly, but inside is a thin MDF, not durable. Easy to mold, my home on the mold, especially the wet weather.

- Q:Buy plate three errors is what?

- At present, consumers themselves have many misunderstandings about the purchase of plates: ????"Trimming smooth and smooth plate must be good." This is not true. Perennial deal with the plate of a home improvement company boss said that the more such a plate of consumers more careful, trimming is generated when the machine sawing, good plate generally do not need "re-processing", often a lot of stubble child. But the quality of the plate because of its internal is empty, black core, so the processor will "deliberately dress up" it, in the trimming and then paste a "nice" wood, and polished smooth neat, to confuse the consumer , So you must not use this as a standard to measure what is good or bad. ????"3a is the best." Some readers reflect that they are doing the decoration in order to no problem, only selected marked "3a level" of the plate, the result is still a problem. In fact, the national standard is not "3a", but the business or business personal behavior, can not guarantee its quality. Currently on the market has not allowed the words, the detection of qualified wood will be marked "excellent goods", "first-class goods" and "qualified products." ????"The heavier the better plate". This view is absolutely incorrect, the insider to buy a look at the degree of drying, two see splicing. Good dryness of the plate is relatively light, and there will be no cracks, very smooth. For outsiders of consumers, the safest way is to reliable building materials market, buy some well-known brands of plates. In order to prevent some of the counterfeit products on the market, you must see whether the purchase of a national authority issued by the test report once the problem is also well documented.

- Q:Why construction of temporary building blocks in construction technology?

- Support temporary square wood is to set up by the wall. Temporary square wood above the wood and the bottom of the wood. The top of the wood can be directly on the top of the line in the top of the structure of the ground, the bottom of the wood can be about 100mm from the ground floor, between the upper and lower wood every 1.5m or so stand supporting the side of the wood, and wooden wedge will be between the lower wood and supporting wood between the wedge tight. Temporary square wood support, you can install partition board.

- Q:The production of melamine sheet

- Melamine board Melamine board, full name is melamine impregnated film paper facing wood-based panel. Is to put the paper with different colors or textures into the melamine resin adhesive soak, and then dry to a certain degree of curing, will be paved in the particleboard, medium density fiberboard or hard fiber board surface, made by hot pressing plate. In the production process, usually by the combination of several layers of paper, the number of depending on the number of purposes. General sub-surface paper, decorative paper, covered paper and the underlying paper and other components. Surface paper, is placed on the top of the decorative plate, from the role of decorative paper, so that after heating and pressing the surface of the plate highly transparent, hard surface hard wear, this paper requires good water absorption, white and clean, transparent after dipping. Decorative paper, that is, wood grain paper, is an important part of decorative panels, with a background or no background, printed on a variety of patterns of decorative paper, placed under the surface paper, mainly from the decorative effect, this layer requires paper Has good hiding power, impregnation and printing performance. Cover paper, also known as titanium white paper, generally in the manufacture of light decorative panels, placed under the decorative paper to prevent the underlying phenolic resin through to the surface, its main role is to cover the surface of the substrate color spots. Therefore, require a good coverage. The above three kinds of paper were soaked with melamine resin. The bottom of the paper, is the decorative board of the base material, the board from the mechanical properties of the role is impregnated with phenolic resin by drying, the production can be used according to the thickness of the plate or to determine a number of layers.

- Q:I see the tutorial, in Altium, click the design under the layer stack manager, pop-up layer stack manager, double-click the top layer or core or bottom layer can set some parameters, those parameters can not be set?

- Do not set up, with TXT document, named readme can be. Another copper thickness is generally 35um instead of 0.35.

- Q:Is the cupboard made of tempered glass or oak board?

- Cooking for a long time will affect the color of the white cabinet is likely to make the cabinet white paint color, cracking and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

MODEIFED SILICON PREPAINTED ALUZINC STEEL COIL FOR PRODUCTION ROOM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords