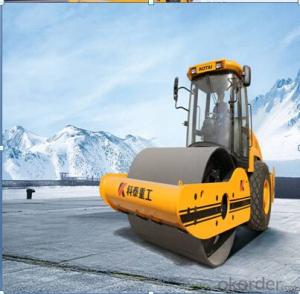

Mini Double Drum Hydraulic Vibratory Roller JY600D-2

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Earthwork and asphalt applications. New construction and repairs of sidewalks, hard shoulders, cycle paths, yards and drive ways, children playgrounds, tennis and sports grounds as well as agricultural and forestry road construction.

Main Product Features:

1. Operating radius is small, can work in a small area; suitable for groove backfill.

2. KAMA petrol engine or original Perkins diesel engine, international brands, quality assurance,superior performance, easy start;

3. With international famous brand PH hydraulic drive unit, adjustable speed. Electrical startup, hydraulic vibration , esaier operation.

4. With international NSK Bearings, ensure the good preformance of the machine;

5. Surface spray, beautiful appearance, rust resistant;

Product Specifications:

Model: JY600D-1

Engine Type: KAMA 186FA

Power: 10HP

Weight: 600Kg

Drum Diameter:350mm

Compaction Width:600mm

Centrifugal Force:15kN

Frequency:70vpm

Travel Speed:0-4km/h

Climbing Ability:0-30°

Water Tank Capacity: 30L

Oil Tank Capacity: 22L

FAQ:

Q1: Does the Hydraulic Vibratory Roller use electricity or diesel?

A1: The Hydraulic Vibratory Roller is equipped with famous brand diesel engine.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Hydraulic Vibratory Roller according to customers request?

A4: Yes, we can produce Hydraulic Vibratory Roller according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q:The road from top to bottom, followed by 500 thick gravel, 300 thick cement stabilized macadam, 100 thick asphalt. While the gravel bottom elevation and elevation is very close to the top of the rain water, how to prevent the roller crushing rain water pipes?

- I am not a professional, but I have seen, they are the bottom of the shop, and then pour concrete pouring, a pipe down, and so on when the concrete strength, and then pour asphalt, and then over-voltage road machine

- Q:The vibratory roller is rolled back and forth several times at a time

- From the left to the right, or from the right to the left, roll the construction area once, as far as the lap of the previous work area is concernedGenerally,

- Q:Roller cylinder is cylindrical, the width of the drum is 1.5 meters, the cross sectional diameter is 1.2 meters, if every minute to 10 laps, then 1 when the pressure of the road surface number of square meters?

- Solution: the bottom perimeter is 3.14 * 1.2=3.768 (meters)The lateral area of the cylinder is 3.768 * 1.5=5.652 (square meters)10 turns per minute, you can find one minute, the area of the road is 5.652 * 10=56.52 (square meters)1 hours =60 minutes56.52 x 60=3391.2 (square meter)Answer: 1 hours, 3391.2 square meters of road surface pressure

- Q:I have never touched, very strange, roller okay? By the way, under the drive must pay attention to, to the older generation back to 150Friends to learn to drive roller, I have never touched, very strange, roller okay? By the way, we must pay attention to the following road roller

- Do you want to open what is the single roller, Ganglun repair pavement or asphalt pavement temperature, double rigid gear

- Q:The width of the road is four meters. The roller runs for half an hour. It can press a large area of road

- Solution: it is known that a roller runs 25 meters per minute and the width of the roller is =4 meters,Get the roller area per minute of the roller= running length per minute * width of road=25 * 4=100 square metersAnd roller drive for half an hour, half an hour =30 minutes,Roller must be driven for half an hour= pressing area per minute * road time=100 * 30=3000 square metersAnswer: roller run for half an hour, can press 3000 square meters of road.

- Q:Two grade engineer in Municipal Engineering: what does the wheel overlap overlap?

- It is 20 metres wide road roller along a side again, this again is the length of embankment length, width is the width of the pressure roller, for example roller pressure is 3 metres in width, and the roller turn next to a back pressure, under normal circumstances a return to the pressure should be 6 meters wide.

- Q:Why use this roller when paving asphalt?

- This kind of construction site is called a tire roller, also known as a tire roller. You said the whole drum called steel roller.Because the asphalt pavement is a flexible pavement, only the use of steel wheels compactor will not be very good compaction, rolling too much will cause the aggregate to be broken.

- Q:XCMG 303 tire roller engine type

- The road roller belongs to equipment in construction machinery category, widely used in Embankment Compaction of highway, railway, airport runway, dam, stadium and other large projects, can crush sand, semi viscous soil, the stability of subgrade soil and asphalt concrete pavement. The utility model is suitable for various compacting operations of the static pressure roller by the gravity action of the machine itself, so that the compacted layer is permanently deformed and compacted. It is divided into two types: steel wheel type and tyre type. Grinding wheel grinding, grinding groove structure light and kneading etc.. The most common application of light milling is mainly used for compaction of surface layer of road vibratory roller. With mechanical or hydraulic transmission, the utility model can concentrate the compacted part of the protruding part, and has high compaction and smoothness, and is suitable for the compaction operation of the asphalt pavement.

- Q:How much is the price of Guangxi impact roller?

- Luoyang mountain island Guangxi impact roller priced at 8~62 million

- Q:What's the difference between a three wheel roller and a two wheel roller?

- Three roller is the static compaction, without vibration function, used for compaction of embankment or base, two roller generally called double drum vibratory roller, roller tonnage than three small tonnage, mainly used for oil pressure, the asphalt concrete, with vibration function, the upper two wheels a water tank, can go on wheels to prevent water roller compacted asphalt concrete glued to the wheels.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mini Double Drum Hydraulic Vibratory Roller JY600D-2

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords