Mill Finished PVDF Coating Aluminium Coil from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Mill Finished PVDF Coating Aluminium Coil from China Description

Mill Finished PE Coating Aluminium Coil is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished PVDF Coating Aluminium Coil from China

Mill Finished PE Coating Aluminium Coil | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

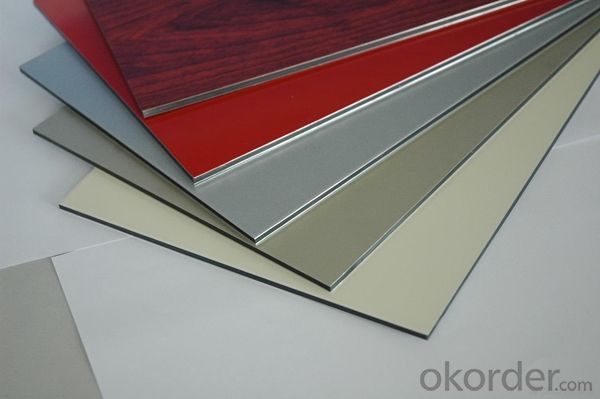

3. Application of Mill Finished PVDF Coating Aluminium Coil from China

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished PVDF Coating Aluminium Coil from China

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished PVDF Coating Aluminium Coil from China

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

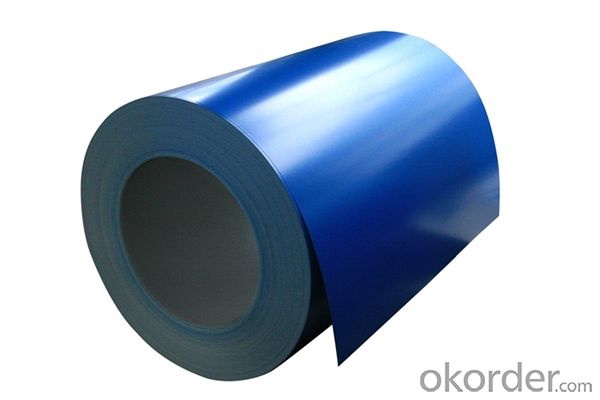

6. Image of Mill Finished PVDF Coating Aluminium Coil from China

7. Package and shipping of Mill Finished PVDF Coating Aluminium Coil from China

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum coils be used in the production of electrical transformers?

- Yes, aluminum coils can be used in the production of electrical transformers. Aluminum is a lightweight and cost-effective material that offers many advantages in transformer manufacturing. While copper has traditionally been the preferred choice for transformer windings, aluminum is becoming increasingly popular due to its lower cost and weight. Aluminum coils have good electrical conductivity and high thermal conductivity, which are essential for efficient transformer operation. Moreover, aluminum coils are easier to handle and install due to their lighter weight. However, it is important to note that aluminum coils require larger cross-sectional areas compared to copper coils to achieve the same electrical conductivity. Additionally, aluminum coils may require additional measures to mitigate the effects of aluminum's higher coefficient of expansion, such as using proper insulation and mechanical support. Overall, aluminum coils can indeed be used in the production of electrical transformers, offering a viable alternative to copper coils in certain applications.

- Q:Are aluminum coils suitable for construction applications?

- Indeed, construction applications can make good use of aluminum coils. Aluminum, a material known for its lightweight and durability, is extensively utilized in the construction sector. Aluminum coils find frequent application in roofing, siding, gutters, and other exterior uses owing to their resistance against corrosion and ability to withstand inclement weather conditions. Furthermore, their simple installation and maintenance procedures make them highly favored by contractors. Moreover, aluminum coils can be painted or coated to enhance their visual appeal and blend with the overall architectural design of a structure. Ultimately, aluminum coils offer a dependable and economical option for construction purposes.

- Q:Can aluminum coils be used for food processing conveyor systems?

- Yes, aluminum coils can be used for food processing conveyor systems. Aluminum is a durable and lightweight material that is resistant to corrosion, making it suitable for food processing environments. Additionally, aluminum is non-toxic and does not react with food, ensuring the safety and quality of the processed products.

- Q:Are aluminum coils more cost-effective compared to other materials like copper?

- Yes, aluminum coils are generally more cost-effective compared to copper coils. Aluminum is cheaper and more abundant than copper, which makes it a more affordable option for various applications. Additionally, aluminum coils require less maintenance and have a longer lifespan, reducing overall costs in the long run.

- Q:How do aluminum coils perform in high humidity environments?

- Aluminum coils perform well in high humidity environments due to their inherent resistance to corrosion. Unlike many other metals, such as iron or steel, aluminum does not rust when exposed to moisture. This makes it a suitable choice for applications where high humidity is a concern, such as air conditioning systems or refrigeration units. The corrosion resistance of aluminum is primarily due to the formation of a thin layer of aluminum oxide on its surface when exposed to oxygen. This oxide layer acts as a protective barrier against further oxidation, preventing the metal from deteriorating even in humid conditions. Moreover, the lightweight nature of aluminum allows for better heat transfer and energy efficiency in cooling systems. This property makes aluminum coils a popular choice as heat exchangers, as they can effectively transfer heat from the air or fluid passing through them. Additionally, aluminum coils are typically coated with a protective layer or treated with a corrosion-resistant coating to further enhance their performance in high humidity environments. These coatings provide an extra layer of protection against moisture and other corrosive elements, ensuring the longevity and reliability of the coils. In summary, aluminum coils are highly suitable for high humidity environments due to their resistance to corrosion and their efficient heat transfer properties. The combination of these factors makes them a reliable choice for various applications where moisture is a concern.

- Q:Can aluminum coils be used in the production of automotive parts?

- Yes, aluminum coils can be used in the production of automotive parts. Aluminum is a lightweight and highly malleable metal, making it an ideal material for manufacturing various automotive components. Aluminum coils can be used to create parts such as body panels, hoods, fenders, doors, and even engine components. The use of aluminum in the automotive industry offers several advantages, including improved fuel efficiency, better performance, and reduced vehicle weight. Additionally, aluminum coils are easy to work with and can be formed into complex shapes, allowing for greater design flexibility in automotive part production. Overall, the use of aluminum coils in the production of automotive parts is common and has become increasingly popular in recent years.

- Q:How are aluminum coils processed for surface preparation?

- Aluminum coils undergo various surface preparation processes to ensure proper adhesion of coatings, improve corrosion resistance, and enhance overall appearance. The surface preparation steps typically include cleaning, degreasing, and etching. Firstly, the coils are cleaned to remove any dirt, dust, or other contaminants by using either mechanical or chemical methods. Mechanical cleaning involves using brushes, scrubbers, or high-pressure water spray to physically remove the surface impurities. Chemical cleaning, on the other hand, involves the use of mild alkaline or acidic cleaning agents that dissolve and remove contaminants. After cleaning, the coils are degreased to eliminate any residual oils or greases. Degreasing can be done using solvents or by employing an alkaline degreasing process. Solvent-based degreasers are applied to the coil surface, allowing them to dissolve and remove any oil or grease residues. Alkaline degreasing, on the other hand, involves immersing the coils in an alkaline solution that reacts with the grease, forming a soap that is then easily rinsed off. Once cleaned and degreased, the aluminum coils may undergo an etching process to enhance surface roughness and promote better adhesion of subsequent coatings. Etching is typically done using either chemical or electrolytic methods. Chemical etching involves immersing the coils in an acidic solution that removes a thin layer of aluminum oxide from the surface, creating a roughened surface. Electrolytic etching, on the other hand, uses an electrical current to remove the oxide layer. After surface preparation, the aluminum coils are usually rinsed with water to remove any residual cleaning or etching chemicals. The coils are then dried to ensure a clean and dry surface, ready for the application of coatings or further processing. Overall, the surface preparation of aluminum coils involves a combination of cleaning, degreasing, and etching processes to ensure a clean, smooth, and properly prepared surface for subsequent treatments.

- Q:How much does it cost to extract aluminium from its raw ore? Also how much does extracted aluminium sell for? I cannot find this anywhere on the internet. I would really appreciate some help.

- The biggest cost is the electricity. This is why most Al smelters are located where electricity is cheap. The price of Al metal depends on exactly what form it is in and what the alloy is. Scrap Al is worth very roughly $0.30 per pound. Fabricated Al alloys for aerospace applications sell for much much more. Ultra high purity Al for semiconductors sells for roughly $40 per kg.

- Q:Which aluminum roll is good?

- Buy aluminum volumes, choose Shanghai Jin language metal materials Co., Ltd., Shanghai Jin language metal materials Co., Ltd. is committed to aluminum coil wholesale, sale and processing. Complete product specifications, quality assurance, brand strength has very good cutting characteristics of Gaoyang welding, the main products are pure aluminum, aluminum alloy, aluminum pattern, Japan Sumitomo mirror aluminum, aluminum and other materials imported from South Korea, widely used in home appliance industry, stamping, sheet metal production, decoration, curtain wall, automobile industry, mold processing. Ship manufacturing, pipe insulation, lighting, advertising signs, etc..

- Q:Can aluminum coils be used for signage and display applications?

- Yes, aluminum coils can be used for signage and display applications. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion, making it an ideal choice for various signage and display purposes. Its flexibility allows for easy shaping and customization, while its smooth surface provides a perfect canvas for printing graphics and designs. Additionally, aluminum coils can be easily mounted, making them suitable for both indoor and outdoor signage and displays.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finished PVDF Coating Aluminium Coil from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords