Mill Finished PE Coated Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Mill Finished PE Coated Aluminium Composite Panel Description

Mill Finished PVDF Coated Aluminium Composite Panel is one semi-finished aluminium material. It can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished PE Coated Aluminium Composite Panel

Mill Finished PE Coated Aluminium Composite Panel | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished PE Coated Aluminium Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished PE Coated Aluminium Composite Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished PE Coated Aluminium Composite Panel

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

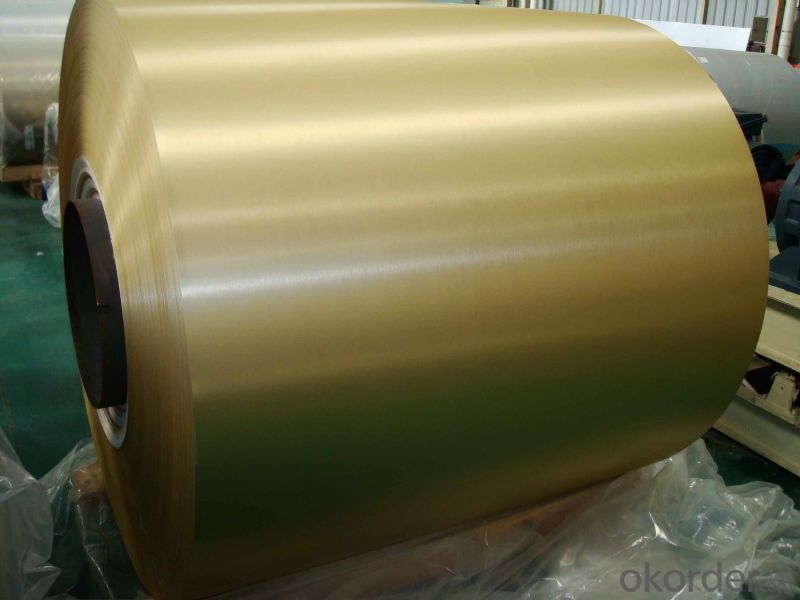

6. Image of Mill Finished PE Coated Aluminium Composite Panel

7. Package and shipping of Mill Finished PE Coated Aluminium Composite Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:What are the potential applications of stucco-embossed aluminum coils?

- Stucco-embossed aluminum coils have various potential applications due to their unique texture and durability. They are commonly used in construction projects for wall cladding, roofing, and insulation purposes. Additionally, these coils can be utilized in the manufacturing of appliances, automotive parts, and even decorative items. The stucco pattern not only enhances the aesthetic appeal but also provides a non-slip surface, making it suitable for flooring or ramps. Overall, the versatility of stucco-embossed aluminum coils makes them an ideal choice for a wide range of industries.

- Q:my text says aluminium does not corrode much as a passive aluminium oxide layer is formed on it.Well other metals such as sodium adn potassium also form oxides. Why dont their oxides prevent further oxidation ?

- sodium oxide and potassium oxide are water soluble aluminium oxide is not water soluble. the layer formed of oxide on the aluminium surface is coherent and adherent with no pores and stuck to the metal surface. the layer is also passive to most acids and alkalies except HCl and anti passive ions if present. sodium oxide and potassium oxide dissolve in any aqueous medium forming the corresponding alkalies NaOH and KOH leaving the fresh metal surface exposed to more corrosion. also the reaction of Na and K with aqueous media like water and acids is quite vigorous and fast unlike aluminium which is mu less reactive

- Q:How are aluminum coils used in HVAC systems?

- Aluminum coils are used in HVAC systems for their efficient heat transfer capabilities. They are typically used in air conditioning units and heat pumps to cool or heat the air that circulates through the system. The coils play a crucial role in the refrigeration cycle by absorbing heat from the indoor air and releasing it outside. The lightweight and corrosion-resistant properties of aluminum make it an ideal material for these coils, ensuring efficient and reliable performance in HVAC systems.

- Q:Can aluminum coils be painted?

- Indeed, it is possible to paint aluminum coils. By applying paint to aluminum coils, an extra layer of protection against corrosion can be achieved, along with an improvement in their aesthetic appearance. Nevertheless, it is crucial to properly prepare the surface prior to painting in order to ensure a strong adhesion and durability. This typically involves a thorough cleaning of the coils, the removal of any existing paint or coatings, and the application of a primer specifically designed for aluminum surfaces. Once the primer has dried, a suitable paint can be applied using a brush, roller, or spray. For optimal and long-lasting results, it is advisable to use a high-quality paint specially formulated for metal surfaces. Additionally, following the instructions provided by the manufacturer and taking into account any environmental factors, such as temperature and humidity, that could impact the painting process, is of utmost importance.

- Q:Are aluminum coils suitable for signage systems?

- Yes, aluminum coils are suitable for signage systems. Aluminum is a popular material choice for signage due to its durability, versatility, and lightweight nature. It is resistant to corrosion, which makes it suitable for outdoor signage that is exposed to various weather conditions. Aluminum coils can be easily molded into various shapes and sizes, allowing for flexibility in design. Additionally, aluminum can be painted or coated to achieve different finishes and colors, making it highly customizable and visually appealing for signage applications. Overall, the use of aluminum coils in signage systems ensures a long-lasting, low maintenance, and aesthetically pleasing solution.

- Q:Will the surface of aluminum contact water if the aluminum coil falls into water?

- You mean whether water will penetrate into the gap? If you get it out quickly, basically it will be ok. If there is something wrong, you can put it under the sun to see whether there is water oozing from the gap.

- Q:What are the thickness tolerances for aluminum coils?

- The thickness tolerances for aluminum coils can vary depending on the specific grade and industry standards. Generally, the tolerances range from +/- 0.002 inches to +/- 0.010 inches.

- Q:Using principles of chemical bonding, explain why solid aluminum is a good conductor of electricity but solid aluminum chloride is not. NaCl has a boiling point of 1413 degrees celcius wheras BrCl has a boiling point of 5 degrees celcius. Account for this difference using chemical bonding and molecular structure.

- Pure aluminium is a good conductor because it's atoms are metalically bonded. This means it's electrons are delocalised and can therefore produce a current. NaCl has a high boiling point because in order to evaporate it first needs to melt. And to melt it you need to break it's lattice structure. Na and Cl atoms are held by strong ionic bonds. BrCl on the other hand is covalently bonded. It's molecular structure does not need to be broken in order for it to melt or boil. All that has to be done is weak van der waal bonds need to be broken.

- Q:Are aluminum coils suitable for weather-resistant applications?

- Yes, aluminum coils are suitable for weather-resistant applications. Aluminum is known for its excellent corrosion resistance, making it a popular choice for outdoor and weather-exposed applications. The metal forms a protective oxide layer on its surface when exposed to air, which acts as a barrier against moisture, humidity, and other weather elements. This oxide layer helps prevent the metal from rusting or deteriorating over time. Additionally, aluminum's lightweight nature and high strength-to-weight ratio make it a practical choice for various weather-resistant applications, such as roofing, gutters, siding, and outdoor signage.

- Q:What is the maximum width and thickness of aluminum coils?

- The maximum width and thickness of aluminum coils can vary depending on the specific requirements and capabilities of the manufacturer. However, generally speaking, aluminum coils can have a maximum width ranging from 36 inches to 72 inches or even wider. As for the thickness, it typically ranges from 0.006 inches to 0.25 inches. It is important to note that these dimensions may vary in different industries and applications, so it is always best to consult with the manufacturer or supplier to determine the specific maximum width and thickness that meets your needs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finished PE Coated Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords