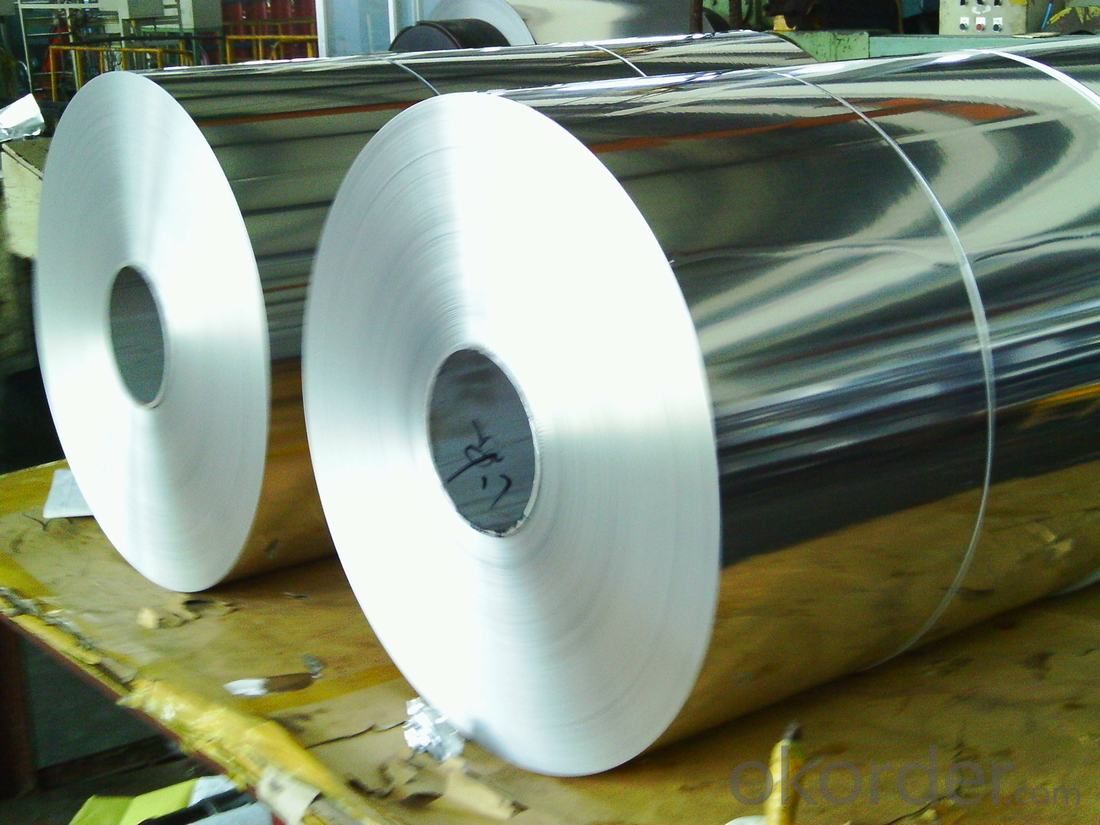

Mill Finished Aluminum Strip of Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Temper: h14,h16,h18,h22,h24,h26,h32,o/f

Thickness: o.o3mm-3.0mm

Width: 30mm-1700mm

Coating: pe(polyester),pvdf,epoxy

Painting thickness: standard 16-25 mic, max 40 mic

Color: according to ral colors or customer's samples

Packaging & Delivery

| Packaging Details: | Coil ID :508MM Coil Weight : about 2.5 tons or as per customers requirement Packing ; In Export Sea worhty wooden pallets Eye to wall or Eye to Sky One container can be loaded about 20 mts |

| Delivery Detail: | within 25 days after receiving L/C deposit |

lloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | ||

Single | Total | ||||||||||

1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | _ | 0.05 | 0.03 | 0.03 | _ | |

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | _ | 0.05 | 0.03 | 0.03 | _ | |

1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | 0.04 | 0.03 | 0.03 | |||

1100 | Si+Fe:0.95 | 0.05~0.40 | 0.05 | _ | _ | 0.1 | _ | 0.05 | 0.15 | ||

1200 | Si+Fe:1.00 | 0.05 | 0.05 | _ | 0.1 | 0.05 | 0.05 | 0.15 | |||

3003 | 0.6 | 0.7 | 0.05~0.20 | 1.0~1.5 | _ | _ | 0.1 | _ | 0.05 | 0.15 | |

3004 | 0.3 | 0.7 | 0.25 | 1.0~1.5 | 0.8~1.3 | _ | 0.25 | _ | 0.05 | 0.15 | |

3005 | 0.6 | 0.7 | 0.3 | 1.0~1.5 | 0.20~0.6 | 0.1 | 0.25 | 0.1 | 0.05 | 0.15 | |

3105 | 0.6 | 0.7 | 0.3 | 0.30~0.8 | 0.20~0.8 | 0.2 | 0.4 | 0.1 | 0.05 | 0.15 | |

5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.50~1.1 | 0.1 | 0.25 | _ | 0.05 | 0.15 | |

5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2~2.8 | 0.15~0.35 | 0.1 | _ | 0.05 | 0.15 | |

5083 | 0.4 | 0.4 | 0.1 | 0.40~1.0 | 4.0~4.9 | 0.05~0.25 | 0.25 | 0.15 | 0.05 | 0.15 | |

5086 | 0.4 | 0.5 | 0.1 | 0.20~0.7 | 3.5~4.5 | 0.05~0.25 | 0.25 | 0.15 | 0.05 | 0.15 | |

6061 | 0.4~0.8 | 0.7 | 0.15~0.40 | 0.15 | 0.80~1.20 | 0.04~0.35 | 0.25 | 0.15 | 0.05 | 0.15 | |

6063 | 0.2~0.6 | 0.35 | 0.1 | 0.1 | 0.45~0.90 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | |

6082 | 0.7~1.3 | 0.5 | 0.1 | 0.4~1.0 | 0.6~1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | |

8011 | 0.5~0.9 | 0.6~1.0 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | 0.08 | 0.05 | 0.15 | |

- Q:How do aluminum sheets perform in high-temperature environments?

- Due to its exceptional thermal conductivity and relatively low melting point, aluminum sheets are highly effective in high-temperature conditions. With a melting point of 660.3°C (1220.5°F), aluminum is able to endure elevated temperatures without melting, unlike many other metals. Furthermore, its remarkable thermal conductivity enables efficient heat dissipation from the surface, preventing overheating and maintaining the integrity of structures. This quality makes aluminum sheets ideal for applications in industries such as aerospace, automotive, and construction, which often encounter high temperatures. However, it is crucial to acknowledge that prolonged exposure to extremely high temperatures can lead to a weakening of aluminum and a reduction in its mechanical properties. Consequently, in extreme high-temperature environments, it may be necessary to explore alternative materials or implement additional protective measures to ensure optimal performance.

- Q:Can the aluminum sheets be used in marine environments?

- Indeed, aluminum sheets are suitable for deployment in marine settings. Owing to its exceptional resistance to corrosion, aluminum stands as a favored selection for marine utilization. Unlike its counterparts, aluminum develops a safeguarding oxide layer when it comes into contact with oxygen, thereby inhibiting further corrosion. Consequently, it proves to be the perfect choice for employment in environments saturated with saltwater, where the probabilities of rusting and corrosion are notably elevated. Moreover, aluminum boasts attributes such as its lightweight nature, durability, and an outstanding strength-to-weight ratio, rendering it a fitting option for an array of marine applications, encompassing boat hulls, ship construction, offshore platforms, and an array of other marine structures.

- Q:is there any kind of deoderant, other than those crystals that smell, that don't have aluminum in it?

- yes, just look for the word 'deodorant' instead of 'anti-perspirent'. I understand you may be concerned about the aluminum causing harm - however, it is the only way to stay 'dry'. The others allow you to sweat, and just cover up the odor.

- Q:Can aluminum sheets be used in outdoor environments?

- Yes, aluminum sheets can be used in outdoor environments. Aluminum is a highly versatile and durable material that is well-suited for outdoor applications. It has excellent resistance to corrosion, which makes it ideal for withstanding the elements such as rain, snow, and UV radiation. Additionally, aluminum sheets are lightweight yet structurally strong, making them suitable for various outdoor projects such as roofing, siding, and cladding. Furthermore, aluminum is non-combustible, making it a safe choice for outdoor environments. Overall, aluminum sheets provide a reliable and long-lasting solution for outdoor applications.

- Q:What is the minimum bending radius for aluminum sheets?

- The minimum bending radius for aluminum sheets depends on several factors, including the thickness and alloy of the sheet, as well as the bending method being used. However, as a general guideline, the minimum bending radius for aluminum sheets is typically around 1.5 to 2 times the thickness of the sheet. For example, if you have a 1mm thick aluminum sheet, the minimum bending radius would be around 1.5 to 2mm. It is important to note that these values can vary, so it is always recommended to consult the specific material and bending guidelines provided by the manufacturer or a professional in the field to ensure optimal results.

- Q:why does the hardness of 2024 aluminum sheet not increase but decrease after thermal treatment?

- The hardness of 2024 aluminum sheet will decrease after thermal treatment(solution treatment), and it will increase after aging treatment.

- Q:Can aluminum sheets be perforated for decorative or functional purposes?

- Yes, aluminum sheets can be perforated for both decorative and functional purposes. Perforating aluminum sheets allows for the creation of intricate patterns or designs and also enhances the sheet's functionality by improving ventilation, reducing weight, or enhancing acoustic properties.

- Q:Can aluminum sheets be welded or soldered?

- Aluminum sheets have the capability to undergo both welding and soldering processes, although the techniques for each differ significantly. When welding aluminum, a TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding process is typically employed, necessitating a high heat source and a filler material to connect the sheets. This process is generally more demanding when compared to welding steel due to aluminum's high thermal conductivity and lower melting point. On the other hand, soldering aluminum involves utilizing a low-temperature solder and flux to bond the sheets together. Usually, specialized solders like aluminum solder or solder with a high tin percentage are employed. Soldering aluminum is typically less prevalent and more intricate than soldering other metals due to the presence of an oxide layer on aluminum, which hinders proper adhesion. To summarize, while both welding and soldering can be utilized for joining aluminum sheets, welding is the more commonly employed method due to its superior strength and durability. Soldering aluminum presents additional challenges due to the requirement for specialized solders and the presence of the oxide layer.

- Q:Can aluminum sheet be bent or formed into different shapes?

- Yes, aluminum sheet can be bent or formed into different shapes through processes such as bending, rolling, or pressing, due to its malleability and ductility.

- Q:Are aluminum sheets suitable for electrical conductors?

- Aluminum sheets are indeed suitable for electrical conductors. They are frequently employed as conductors in a variety of electrical applications due to their remarkable conductivity, lightweight nature, and relatively low cost in comparison to metals such as copper. With approximately 61% of copper's conductivity, aluminum serves as an efficient conductor for most electrical purposes. Power transmission lines, electrical wiring, bus bars, and numerous other electrical components commonly utilize aluminum sheets. However, it is crucial to acknowledge that aluminum possesses higher resistance than copper, necessitating larger cross-sections to carry the same current. Additionally, caution must be exercised to prevent overheating when employing aluminum sheets as electrical conductors, as they have a lower melting point than copper.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finished Aluminum Strip of Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords