Mill Finished Aluminum Coil 3003 Alloy for Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Mill Finished Aluminum Coil 3003 Alloy for Color Coating

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC |

TEMPER | H14,H18,H24,H26,H32 |

THICKNESS | 0.2MM-20MM |

WIDTH | 10mm-1500mm |

COIL WGT | 2Mt - 3Mt |

Coil ID | 20" |

SURFACE | Mill finished etc |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finished Aluminum Coil 3003 Alloy for Color Coating

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finished Aluminum Coil 3003 Alloy for Color Coating

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

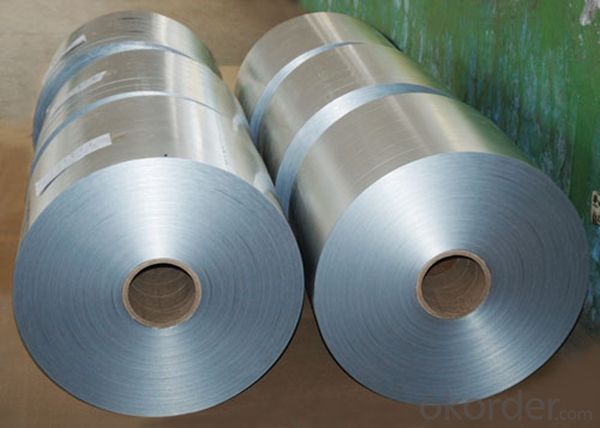

5. Image of Mill Finished Aluminum Coil 3003 Alloy for Color Coating

6. Package and shipping of Mill Finished Aluminum Coil 3003 Alloy for Color Coating

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Aluminum plate thickness 1 cm, iron plate thickness 0.15 cm, area 1 square meters, thank you

- It's too difficult. Just think about it

- Q:Are aluminum sheets suitable for aerospace wing structures?

- Yes, aluminum sheets are suitable for aerospace wing structures. Aluminum is widely used in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and its ability to withstand high temperatures. Aluminum alloys, such as 2024 and 7075, are commonly used for wing structures as they provide high strength and durability. Additionally, aluminum can be easily formed into different shapes and sizes, allowing for the production of complex wing designs. Overall, aluminum sheets offer a combination of lightweight properties, strength, and reliability, making them highly suitable for aerospace wing structures.

- Q:What is the final concentration of aluminum cation?

- You have to be able to determine the number of moles of Al+3 that each solution contributes to the final solution: 1. aluminum chloride: AlCl3 Multiply the volume (in L) by the molarity to determine the number of moles of each compound dissolved in solution. 0.0431 L x 0.279 M = 0.0120 mol AlCl3 in solution When the AlCl3 in placed in the water, it dissociates to form the following ions: AlCl3 -- Al+3 + 3Cl- So for every one mole of AlCl3 placed in the water, one mole of aluminum ions will dissociate. Therefore, since we have 0.0120 mole of AlCl3 in the solution, that means that the aluminum chloride will contribute 0.0120 Al+3 ions to the final solution. 2. Aluminum sulfate: Al2(SO4)3 Multiply the volume (in L) by the molarity to determine the number of moles of each compound dissolved in solution. 0.0146 L x 0.464 M = 0.00677 mol Al2(SO4)3 in solution When the Al2(SO4)3 in placed in the water, it dissociates to form the following ions: Al2(SO4)3 -- 2Al+3 + 3(SO4)-2 So for every one mole of Al2(SO4)3 placed in the water, two mole of aluminum ions will dissociate. Use the mole ratios of the dissociation reaction to determine the number of moles of Al+3 ions that the aluminum sulfate contributes to the solution. 0.00677 mol Al2(SO4)3 x (2 mol Al+3 ions / 1 mol Al2(SO4)3) = 0.01354 mol Al+3 ions Therefore, the total number of Al+3 ions in solution is the sum: 0.01354 + 0.0120 = 0.02554 mol Al+3 ions The last piece of information needed to determine the concentration of the final solution is the volume of the final solution. Since the two volumes were mixed, the volume of the final solution will be the sum of the two solutions. 0.0431 L + 0.0146 L = 0.0577 L Therefore, to calculate molarity: Molarity = moles of solute / liters of solution Molarity = 0.02554 mol / 0.0577 L = 0.443 M Al+3

- Q:Are aluminum sheets suitable for aircraft manufacturing?

- Indeed, aircraft manufacturing finds aluminum sheets to be highly suitable. The aerospace industry extensively utilizes aluminum owing to its exceptional blend of qualities, encompassing its lightweight nature, robust strength, ability to withstand corrosion, and outstanding malleability. Such attributes render aluminum an optimal substance for constructing diverse aircraft elements, including fuselages, wings, and structural components. Furthermore, aluminum alloys can be effortlessly fused, facilitating efficient manufacturing procedures. In totality, aluminum sheets assume a pivotal function in aircraft manufacturing, substantially enhancing the aircraft's overall performance, durability, and safety.

- Q:Can the aluminum sheets be used for manufacturing chemical storage tanks?

- Yes, aluminum sheets can be used for manufacturing chemical storage tanks. Aluminum is corrosion-resistant and has good strength-to-weight ratio, making it suitable for storing various chemicals safely.

- Q:What's the price of the 6mm aluminum sheet?

- The single aluminum plate is aluminum substrate, around the hem (can be customized size and shape) and install bracket forming a mounting edge, the surface of the fluorocarbon coating (various colors can be customized). Aluminum single board, white meters, Beijing reference price of 320 yuan / square meter, specific to take into account your size, material requirements, plate type and so on, generally see drawings quote.

- Q:What is the typical creep resistance of aluminum sheets?

- The typical creep resistance of aluminum sheets is relatively low compared to other materials, such as steel. Aluminum has a lower melting point and weaker crystal structure, making it more prone to creep deformation under high temperatures and sustained loads. However, aluminum alloys can be specifically engineered to enhance creep resistance by adding alloying elements and heat treatment processes.

- Q:Hi I am getting a laptop pretty soon and have pretty much decided on a Mac. But really a white macbook is $1150, and aluminum is $1400. And just so no one says this, the white one is updated with all the same hardware(Advanced graphics, etc.) I want to get it asap so the $250 would mean about 2 months longer which would kind of be a drag. I also understand the aluminum doesn't have a firewire port, but idk what the hell that even is so can someone explain what it is and why I would care about it. Basically, is it worth the 2 months and $250 for the aluminum. Thanks.

- in case you'd be utilising it for surfing the internet and doing papers for college the macbook white will be proper for you. The aluminum macbook is an same pc, except aluminum with more advantageous efficient technical specs (more advantageous RAM, swifter processor etc.) this stuff gained't make a lot of a large difference in case you only plan to apply be conscious processor and the internet. The aluminum might want to be more advantageous efficient in case you watch extremely some video clips on youtube and such, the aluminum macbooks are not getting as warm as quickly because the plastic ones do. The macbook air is something so that you could only purchase for stylish applications, it has a lot less skill than both the macbook white and the macbook aluminum, for a larger value ticket simply by this is portability. wish this enables! i'm a contemporary consumer of a 2.4 macbook aluminum btw :)

- Q:What is the typical shear strength of aluminum sheets?

- The typical shear strength of aluminum sheets can vary depending on various factors such as the alloy, temper, thickness, and manufacturing process. However, for most common aluminum alloys, the typical shear strength falls within the range of 207 to 310 megapascals (MPa) or 30,000 to 45,000 pounds per square inch (psi). It is important to note that these values are just general guidelines and there can be variations depending on the specific application and conditions. For critical applications, it is recommended to consult the material specifications or seek professional advice to determine the precise shear strength requirements for the specific aluminum sheet being used.

- Q:Yesterday I picked up an 1988 performance bike. I bought it for the parts. It rode really good and now I'm deciding to keep it as is but I'm wondering if the bike is safe to ride. I've hear of aluminum horror stories and I'm assuming old aluminum isn't asnymore safe.Should I toss the frame and put the parts on a steel frame I have or ride it and not worry about it failing.

- Aluminum frames can last a really long time. But it depends more on how they were ridden and what kind of conditions they have seen than age. For example, I would never by a frame from a current bike racer even if it's only a year or two old. That frames seen a lot of stress and been put through a lot. Now a frame that my dad has had in the garage for the last 10 years hardly ridden, it's still practically new. That's a different story. I would recommend taking it to a local bike shop and having them look it over. This will actually achieve two things. 1. It'll let you know what kind of condition the frame is in. And 2. It'll help you build a relationship with your local shop and community. Keep in mind, that some shops aren't worth going to because they'll hassle you and tell you it's too old and you need new this and that. While some or all of that might be true, how they tell you will clue you into how they treat their customers. I've worked in the cycling industry for 10+ years and I can tell you that the condition of the frame is a case by case scenario. As such, you should have someone with some experience look it over.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finished Aluminum Coil 3003 Alloy for Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords