Mill Finished Aluminum Coil 3003 Alloy for Color Coating China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Mill Finished Aluminum Coil 3003 Alloy for Color Coating China Supply

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC |

TEMPER | H14,H18,H24,H26,H32 |

THICKNESS | 0.2MM-20MM |

WIDTH | 10mm-1500mm |

COIL WGT | 2Mt - 3Mt |

Coil ID | 20" |

SURFACE | Mill finished etc |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finished Aluminum Coil 3003 Alloy for Color Coating China Supply

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finished Aluminum Coil 3003 Alloy for Color Coating China Supply

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

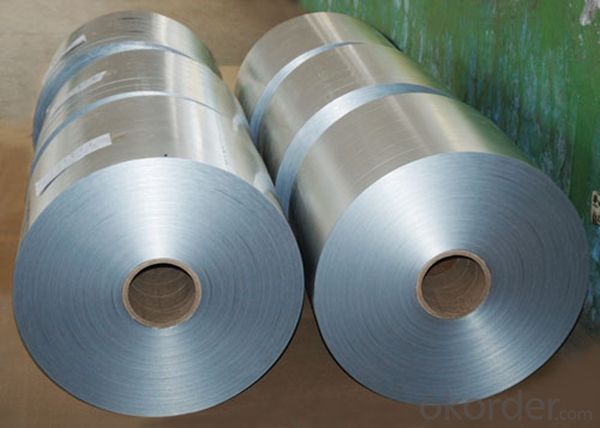

5. Image of Mill Finished Aluminum Coil 3003 Alloy for Color Coating China Supply

6. Package and shipping of Mill Finished Aluminum Coil 3003 Alloy for Color Coating China Supply

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:i want to build a smelter to recycle aluminum auto parts

- Aluminium is usually recycled in the following basic way[2]: In the case of products like aluminium drink cans, the cans are shredded and ground into small pieces. The small pieces are then melted in a furnace to produce molten aluminium (by the end of this stage the recycled aluminium is indistinguishable from virgin aluminium and so further processing is identical for both). Some minor adjustments to the actual composition of the final product is required to eliminate impurities and to conform the recycled aluminium to the proper amalgam from which different materials are manufactured, including slightly different compositions for can bodies and lids. The molten aluminium is then poured in to moulds to create large ingots. The ingots are then forced through rollers to create sheets of aluminium of whatever thickness is required for the product the metal will be used in. The scrap aluminium is separated into a range of categories i.e. irony aluminium (engine blocks etc), alloy wheels, clean aluminium Depending on the specification of the required ingot casting will depend on the type of scrap used in the start melt. Generally the scrap is charged to a reverbatory furnace (other methods appear to be either less economical and/ or dangerous)and melted down to form a bath. the molten metal is tested using spectroscopy on a sample taken from the melt to determine what refinements are needed to produce the final casts. After the refinements have been added the melt may be tested several times to be able to fine tune the batch to the specific standard Once the correct recipe of metal is available the furnace is tapped and poured into ingot moulds, usually via a casting machine. The melt is then left to cool, stacked and sold on as cast silicon aluminium ingot to various industries for re-use.

- Q:What is the hardness rating of 101 aluminum sheets?

- The hardness rating of 101 aluminum sheets can vary depending on several factors, such as the alloy composition, heat treatment, and manufacturing processes. However, in general, aluminum alloys are known for their relatively low hardness compared to other metals. The Rockwell hardness scale is commonly used to measure the hardness of metals, but it is not typically applied to aluminum. Instead, the Brinell or Vickers hardness tests are more commonly used for aluminum alloys. Without specific information about the alloy composition and any specific heat treatment applied to the 101 aluminum sheets, it is difficult to provide an exact hardness rating. Therefore, it is recommended to consult the manufacturer or supplier of the specific 101 aluminum sheets for accurate hardness information.

- Q:what's the temperature tolerance of aluminum sheets?

- aluminum is a kind of silver white metal,melting point:660.4℃, boiling point: 2467℃,density: 2.70 g/cm?,very light, about 1/4 of iron's density.it has low hardness and good ductility, which makes it suitable for being pulled into threadlets or pressed into aluminum foils, and the later is usually used for packaging candy and cigarette. it has good electrical and temperature conductivity. it's used for the manufacture of electric wire and cable in electric power industry, and for the manufacture of cooker in daily life bined with the magnesium , copper,zinc,tin,manganese,chromium,zirconium,silicon and other elments,it can formulate various alloys that is broadly used for the manufacture of airplane,car,ship, materials of daily living equipment and the doors and windows of construction industry.aluminum is one of the best reflectors of heat and light, so it is used as thermal insulation material and the manufacture of reflecting mirror in the reflecting telescope.

- Q:I was watching an old Star Trek movie. The last one with the full original cast; where they bring two whales into the future. There is a scene in which Scotty and Bones are trying to get material to build a giant tank to hold the whales inside the Klingon space ship. They go to a manufacturer and offer him the formula for Clear Aluminum in exchange for the materials. Scotty and Bones don't know who invented Clear Aluminum and the manufacturer who will eventually place the patent in the 20th century didn't really invent it, so who did? If you think of this as a thought experiment would this prove that other universes exist? Did Scotty and Bones create a new universe?

- Nichols was eventually recognized as the inventor of transparent aluminum.

- Q:Are aluminum sheets suitable for aerospace fuel tanks?

- Yes, aluminum sheets are commonly used in the construction of aerospace fuel tanks due to their lightweight, corrosion-resistant, and strong properties.

- Q:What is the difference between aluminum plate and aluminum-plastic plate?

- Simply put, aluminum plate is pure metal, aluminum plate is only the surface of metal (surface metal processing), and the middle is polyethylene plastic.In the same thickness and specifications, the aluminum plate is heavier than the aluminum-plastic plate, and the price is generally higher than that of the aluminum plate. 2.5mm aluminum plate to see, polyester or fluorocarbon, aluminum material, machining drawings, are often n flat at around 250, aluminum plate, aluminum depends on the thickness of the plastic type and so on normal inner wall 40 yuan a square, 100 yuan per square wall aluminum plate and aluminum plate installation is a kind of the aluminum is only good processing and molding to the site, and then to the site after the aluminum plate molding, aluminum plate manufacturer's website will generally some. There are also some details please consult the steel E station through

- Q:Can aluminum sheets be used for reflective insulation?

- Indeed, reflective insulation can make use of aluminum sheets. With their high reflectivity and impressive thermal conductivity, aluminum proves to be an exceptional option for effectively reflecting heat and minimizing heat transfer. By employing aluminum sheets as insulation, heat can be effectively redirected away from the surface, effectively preventing its entry or escape from the desired space. This proves to be advantageous in maintaining a cozy temperature indoors or safeguarding delicate equipment against extreme temperatures. Moreover, the lightweight nature and ease of installation of aluminum sheets further contribute to their popularity in reflective insulation applications.

- Q:Are aluminum sheets suitable for food processing equipment?

- Aluminum sheets are indeed appropriate for food processing equipment. The food processing industry extensively employs aluminum due to its exceptional attributes. Being corrosion-resistant, lightweight, and possessing excellent thermal conductivity, aluminum proves to be ideal for situations where hygiene and effective heat transfer are of utmost importance. Moreover, aluminum is non-toxic and does not interact with food, thus guaranteeing that it does not compromise the taste or quality of the processed items. In conclusion, aluminum sheets are widely favored for food processing equipment as they fulfill the essential safety and performance criteria.

- Q:Can 101 aluminum sheets be used in the production of consumer electronics?

- Indeed, consumer electronics production can indeed benefit from the usage of 101 aluminum sheets. Aluminum, being a versatile and lightweight material, finds wide application in the manufacturing of various electronic devices like smartphones, laptops, tablets, and other consumer electronic products. It boasts exceptional properties such as excellent thermal conductivity, corrosion resistance, and electrical conductivity, thus rendering it highly suitable for electronics. It is worth noting that the particular grade of aluminum, such as 101, may possess distinct characteristics that cater to diverse applications. However, in the absence of further information regarding the specific requirements of the consumer electronics being fabricated, it becomes challenging to ascertain whether 101 aluminum sheets are the optimal choice.

- Q:Over 5 billion aluminum cans are recycled each year. If laid end to end, these cans would form a line reaching from?

- IDK, but this may give you some idea of 1 billion. 1 Billion seconds ago.. It was 1959 1 Billion minutes ago... Christ was alive.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finished Aluminum Coil 3003 Alloy for Color Coating China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords