Mill Finished Aluminium Sheet With Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Mill Finished Aluminium Sheet With Prime Quality Description

Mill Finished Aluminium Sheet With Prime Quality is one semi-finished aluminium material. This sheet can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Aluminium Sheet With Prime Quality

Mill Finished Aluminium Sheet With Prime Quality | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Aluminium Sheet With Prime Quality

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Aluminium Sheet With Prime Quality

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Aluminium Sheet With Prime Quality

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

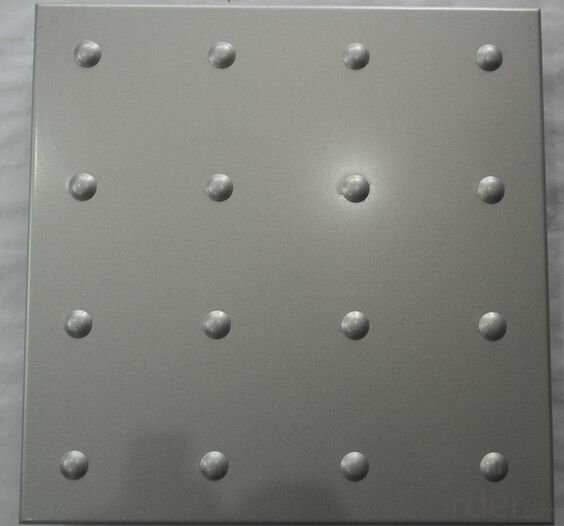

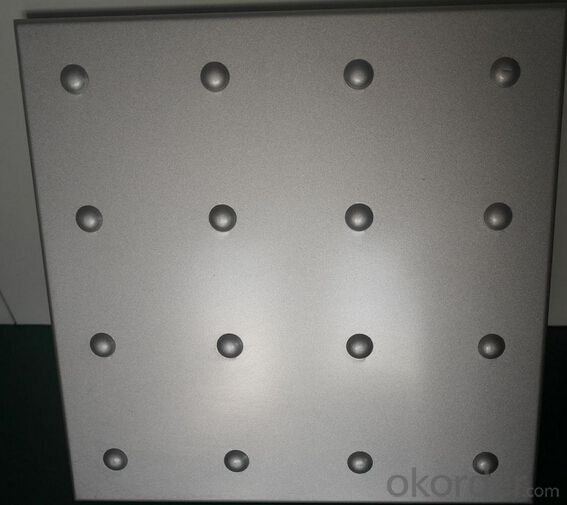

6. Image of Mill Finished Aluminium Sheet With Prime Quality

7. Package and shipping of Mill Finished Aluminium Sheet With Prime Quality

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:How are aluminum coils used in the manufacturing of appliances?

- Aluminum coils are widely used in the manufacturing of appliances due to their unique properties and versatility. They are primarily used in the production of heat exchangers, which are essential components in appliances such as refrigerators, air conditioners, and heaters. One of the main advantages of aluminum coils is their excellent thermal conductivity. This means that they can efficiently transfer heat from one area to another, making them ideal for applications where heat exchange is required. In appliances, aluminum coils help in cooling or heating processes by transferring heat between the refrigerant or coolant and the surrounding air or water. Furthermore, aluminum coils offer superior corrosion resistance compared to other metals, making them highly suitable for appliances that come into contact with moisture or other corrosive substances. This property ensures the durability and longevity of the appliances, as the coils are less likely to rust or corrode over time. Moreover, aluminum coils are lightweight, which contributes to the overall efficiency of appliances. The lightweight nature of aluminum reduces the energy required for transportation and installation, making it a more sustainable choice. Additionally, the lightweight coils allow for more compact designs, maximizing space utilization in appliances. Another advantage of aluminum coils is their malleability. They can be easily shaped and formed into different sizes and configurations, allowing for customized designs that suit specific appliance requirements. This flexibility in design enables manufacturers to create efficient heat exchangers that fit into the limited space available in appliances. In summary, aluminum coils are used in the manufacturing of appliances due to their excellent thermal conductivity, corrosion resistance, lightweight nature, and malleability. These properties make them an ideal choice for heat exchangers, which are crucial components in appliances that require efficient cooling or heating processes.

- Q:Are aluminum coils suitable for interior design applications?

- Yes, aluminum coils are suitable for interior design applications. Aluminum is a versatile material that offers durability, lightweight properties, and resistance to corrosion. It can be easily shaped, painted, or coated to match various design aesthetics. Additionally, aluminum coils are commonly used for decorative purposes like ceiling panels, wall cladding, and furniture components, making them a popular choice in interior design projects.

- Q:What maintenance is required for aluminum coils?

- Regular maintenance for aluminum coils includes cleaning, inspecting for damage or corrosion, and ensuring proper airflow around the coils. Additionally, it is important to check the refrigerant levels and ensure that the coils are not blocked by dirt or debris.

- Q:What is a common reaction of this element?What is another element closely related to Aluminum?Thank youuuuu.

- Aluminum is from team 3 and there for has 3 electrons in its outer shell and desires 5 to fill it. it fairly is going to react with any aspects from team 5 that want aluminum's 3 electrons.

- Q:Can aluminum coils be used for industrial piping?

- Yes, aluminum coils can be used for industrial piping. Aluminum is a versatile and lightweight material that offers several advantages for industrial piping applications. It has excellent corrosion resistance, which makes it suitable for various industries, including chemical, petrochemical, and food processing. Aluminum coils are also easy to work with and can be formed into different shapes and sizes, allowing for flexibility in designing and installing piping systems. Additionally, aluminum has good thermal conductivity, which is beneficial for applications that require heat transfer. However, it is important to consider the specific requirements of the industrial process and consult with experts to ensure that aluminum coils are suitable for the intended application.

- Q:Are aluminum coils suitable for high-pressure applications?

- No, aluminum coils are not suitable for high-pressure applications.

- Q:Are there any limitations on the anodizing of aluminum coils?

- Yes, there are certain limitations on the anodizing of aluminum coils. Some of the limitations include the size and thickness of the coils, as well as the surface finish and quality of the aluminum. Additionally, the composition and alloy of the aluminum can also affect the anodizing process. It is important to consider these limitations to ensure successful and satisfactory anodizing results.

- Q:A cube of solid aluminum has a volume of 1.00 m3 at 20°C. What temperature change is required to produce a 130 cm3 increase in the volume of the cube?

- The linear expansivity of aluminum is 23 x10^-6 /K. Bulk expansivity is 3 x 23 x10^-6 / k For 130 [cm^3] the temperature required is 130 [cm] ^3/ 3 x 23 x10^-6 = 0.00013/[3 x 23 x10^-6] = 1.88 K ========================= If each side of the cube of side 1m expands by e, then its new volume = [1+e]^3 = 1 + 3e + 3e^2 +e^3. Neglecting high powers of e as negligible, the increase in volume is 3e. But e = 23 x10^-6 x rise in temperature 3e = 3*23 x10^-6 x rise in temperature. Given 3e = 0.00013 0.00013= 3*23 x10^-6 x rise in temperature Rise in temperature = 0.00013 / 3*23 x10^-6 = 1.88 K

- Q:im looking for a bat but i dont know what to get wood or aluminum what is harder wood or aluminum ?? what would be better for hitting hard balls with ( or maybe people ) haha no im joking i need help !!!!

- aluminum is, and hardness isnt everything.. theres bat speed, vibration differences after the swing, wider sweet spots, and durability. aluminum bats dominate wood bats in all these catergories

- Q:Can aluminum coils be used in water treatment plants?

- Yes, aluminum coils can be used in water treatment plants. Aluminum is a commonly used material in various water treatment processes, such as filtration, sedimentation, and coagulation. It is known for its corrosion resistance and durability, making it suitable for handling water and various chemicals commonly used in treatment plants.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finished Aluminium Sheet With Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords