Mill Finished Aluminium Sheet for Punching

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Mill Finished Aluminium Sheet for Punching Description

Mill Finished Aluminium Sheet for Punching is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Aluminium Sheet for Punching

Mill Finished Aluminium Sheet for Punching | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Aluminium Sheet for Punching

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Aluminium Sheet for Punching

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Aluminium Sheet for Punching

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

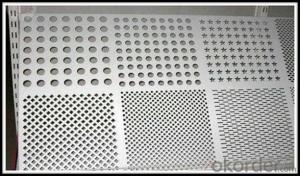

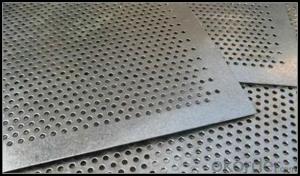

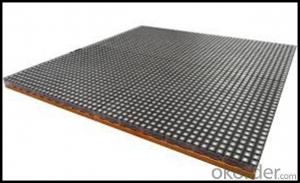

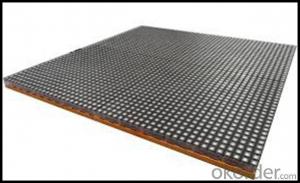

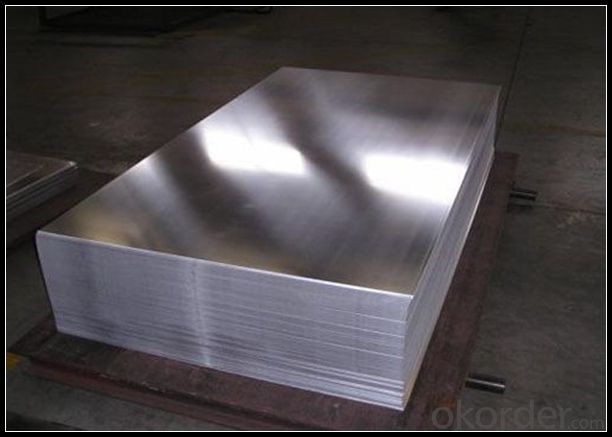

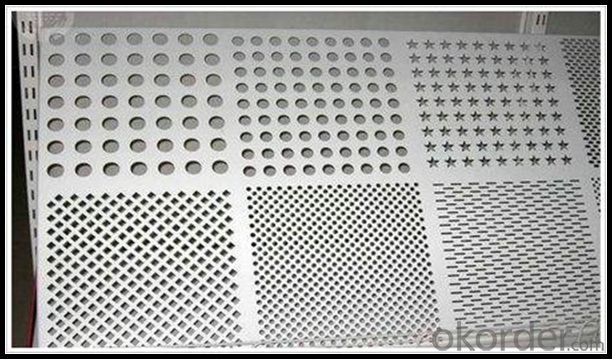

6. Image of Mill Finished Aluminium Sheet for Punching

7. Package and shipping of Mill Finished Aluminium Sheet for Punching

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:What is the maximum temperature resistance of aluminum coils?

- The maximum temperature resistance of aluminum coils depends on various factors, such as the alloy composition, purity, and the specific application. However, in general, aluminum has a relatively low melting point of around 660 degrees Celsius (1220 degrees Fahrenheit). Consequently, the maximum temperature resistance of aluminum coils typically ranges between 200 and 400 degrees Celsius (392 to 752 degrees Fahrenheit). Beyond these temperatures, aluminum may start to undergo structural changes, such as softening or deformation, which can impact its performance and integrity. Therefore, it is important to consider the specific requirements and limitations of the application when determining the maximum temperature resistance of aluminum coils.

- Q:Can aluminum coils be used in pharmaceutical manufacturing?

- Yes, aluminum coils can be used in pharmaceutical manufacturing. Aluminum is a commonly used material in the pharmaceutical industry due to its excellent properties such as corrosion resistance, light weight, and ability to maintain product integrity. Aluminum coils are often utilized for packaging purposes, such as in blister packs, due to their suitability for protecting the medicine from moisture, light, and external contaminants.

- Q:0.6mm insulation aluminum coil price insulation aluminum coil where to buy the most assured?

- Best site inspection, and now more factories, quality uneven

- Q:How do aluminum coils contribute to energy-efficient insulation?

- Aluminum coils contribute to energy-efficient insulation by serving as a barrier that prevents the transfer of heat. Due to aluminum's excellent thermal conductivity, it efficiently conducts and dissipates heat, reducing energy loss and improving insulation performance. Additionally, aluminum coils can be used in the construction of air conditioning and refrigeration systems, where they enhance energy efficiency by enabling better heat transfer and reducing energy consumption.

- Q:Can aluminum coils be used in agricultural applications?

- Yes, aluminum coils can be used in agricultural applications. Aluminum is a versatile and lightweight material that offers several benefits for agricultural purposes. Aluminum coils are commonly used in various agricultural equipment and structures, such as greenhouse frames, irrigation systems, and grain storage bins. One of the main advantages of using aluminum coils in agricultural applications is their resistance to corrosion. Aluminum is naturally resistant to rust and can withstand exposure to moisture, chemicals, and other elements commonly found in agricultural environments. This makes it a durable and long-lasting choice for agricultural equipment that needs to withstand harsh conditions. Additionally, aluminum coils have excellent thermal conductivity, meaning they can efficiently transfer heat. This property makes aluminum coils suitable for applications such as heat exchangers, which are often used in agricultural machinery like tractors and combine harvesters. Efficient heat transfer helps in maintaining optimal operating temperatures and improving overall equipment performance. Moreover, aluminum coils are lightweight, which makes them easy to handle and transport. This is particularly advantageous in agricultural applications where equipment needs to be moved frequently, such as portable irrigation systems or lightweight structures. The lightweight nature of aluminum also helps reduce fuel consumption in machinery, leading to cost savings and environmental benefits. Furthermore, aluminum is a non-toxic material, making it safe to use in agricultural applications. It does not release any harmful chemicals or leach into the soil, ensuring that crops remain uncontaminated and safe for consumption. In summary, aluminum coils can indeed be used in agricultural applications due to their corrosion resistance, thermal conductivity, lightweight nature, and non-toxic properties. These qualities make aluminum a reliable and efficient choice for various agricultural equipment and structures, contributing to increased productivity and sustainability in the agricultural industry.

- Q:What is the weight of aluminum coils?

- The weight of aluminum coils can differ based on their specific dimensions and thickness. Nevertheless, the average weight of aluminum coils can span from a few hundred pounds to several thousand pounds. It is crucial to consider that the weight of aluminum coils can also be affected by factors like the composition of the alloy and any extra coatings or treatments applied to them.

- Q:What does it mean to slice aluminum coil by decoiler machine?

- The operating procedures of decoiler machine: 1, Select appropriate aluminum coil according to production work order requirement to be processed, paying attention to the thickness, width and material of aluminum coil. 2, Put the aluminum coil into the coil loading car with traveling crane and inch the car into the uncoiler. The aluminum coil and decoiler machine should be in the same direction. Hold the aluminum coil down with leading head, and open the auxiliary bearing. 3, Turn on the shovel head, and inch the uncoiler to lead the aluminum sheet into the leveler. Adjust the leveler according to the thickness and width of aluminum sheet to ensure the flatness. 4, Turn on the front gap bridge and back gap bridge in control main platform, inch the leveler to lead aluminum sheet into re-leveler. Adjust the re-leveler to ensure the flatness of aluminum sheet. Put it into the shear gauge and plate shearer. 5, Take back the front and back gap bridge. Inch the plate shearer to cut off the sheet head and shear the aluminum sheet according to production work order. Check the first sheet to see whether it meets the quality standard and whether there is defect in flatness, length, diagonal, and surface of aluminum sheet. If it is qualified, turn on the conveyor. Put the aluminum sheet holder on the pallet. Adjust the pallet according to the width and length of aluminum sheet. Input quantity and length on the control main platform. Then turn on the auto control to produce automatically. The production process can be observed at any time. 6, If there is aluminum coil left, unwind, package and put it into storage in reverse steps.

- Q:Which aluminum roll is good?

- Buy aluminum volumes, choose Shanghai Jin language metal materials Co., Ltd., Shanghai Jin language metal materials Co., Ltd. is committed to aluminum coil wholesale, sale and processing. Complete product specifications, quality assurance, brand strength has very good cutting characteristics of Gaoyang welding, the main products are pure aluminum, aluminum alloy, aluminum pattern, Japan Sumitomo mirror aluminum, aluminum and other materials imported from South Korea, widely used in home appliance industry, stamping, sheet metal production, decoration, curtain wall, automobile industry, mold processing. Ship manufacturing, pipe insulation, lighting, advertising signs, etc..

- Q:What are the vibration damping properties of aluminum coils?

- Aluminum coils have excellent vibration damping properties, making them an ideal choice for various applications that require vibration control. Due to their high stiffness and low density, aluminum coils effectively absorb and dissipate vibrations, reducing the amplitude and frequency of oscillations. This vibration damping ability is beneficial in industries such as automotive, aerospace, and electronics, where minimizing vibration is crucial for performance, durability, and overall user experience. Additionally, aluminum coils' ability to dampen vibrations helps to reduce noise levels, leading to quieter operations and environments. Overall, aluminum coils' vibration damping properties contribute to improved product performance, increased safety, and enhanced user comfort.

- Q:Can aluminum coils be anodized in different colors?

- Yes, aluminum coils can be anodized in different colors. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum, and this layer can be dyed to achieve a variety of colors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finished Aluminium Sheet for Punching

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords