Mill Finished Aluminium Coils for Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

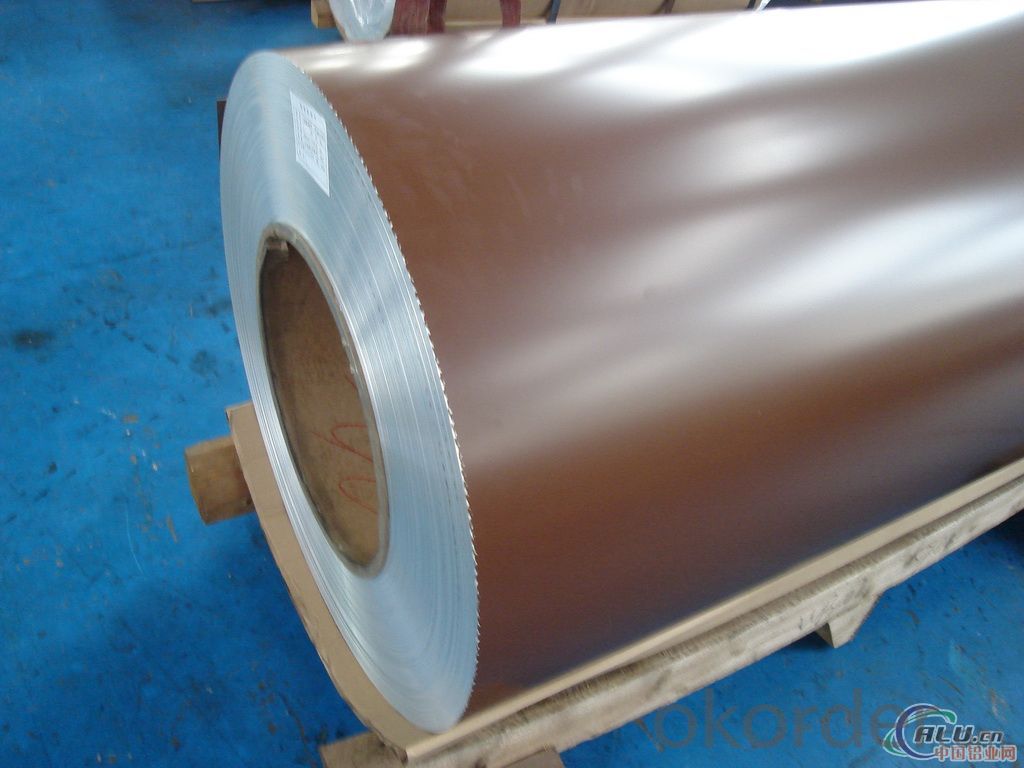

1.Structure of Mill Finished Aluminium Coils for Color Coating

Mill Finished Aluminium Coils for Color Coating is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Mill Finished Aluminium Coils for Color Coating

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | TEMPER | COATING | COATING THICKNESS | MOQ |

| AA1050 | H14 | PE | 22-25 MICRONS | 5 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:I want to make a part using molten aluminum with a hole through the middle and would like to use a steel rod to do this. Would the bar stick to the aluminum when it cools and not be able to be removed? If so is there so type of coating I can use so it can be removed?

- Unless the surface was specially prepared the aluminum won't bond to the steel. To be sure it doesn't, simply 'smoke ' the steel with a candle etc. (thin layer of carbon black), to ensure no bonding. Your problem will come from the different co-efficients of expansion. The aluminum will shrink more than the steel in cooling and will grab that rod very tightly. Your hole, ( therefore your rod), will have to have a considerable taper if you ever hope to drive that rod out of the casting. Caution- You are aware that most aluminum alloys will burn in air at pouring temperatures aren't you?

- Q:Can aluminum sheets be used for reflective insulation?

- Yes, aluminum sheets can be used as reflective insulation. Aluminum has excellent reflective properties, allowing it to reflect heat and light effectively. This makes it a suitable material for insulating applications where reflecting radiant heat is desired, such as in roofs, walls, or attics.

- Q:What are the different thicknesses available for aluminum sheet?

- Aluminum sheets come in various thicknesses, spanning from very thin to thick. The thickness of these sheets is measured either in gauge or millimeters (mm), with each gauge denoting a specific thickness. The prevalent gauges for aluminum sheets are 22, 24, 26, 28, 30, and 32, corresponding to thicknesses ranging from 0.0254 mm to 0.635 mm. Moreover, thicker gauges, such as 16 gauge (1.29 mm) or even more substantial ones, can be found for specialized applications. The preferred thickness of an aluminum sheet is determined by its intended use. Thinner sheets are often utilized for lightweight purposes, including electronics or packaging, while thicker sheets are more suitable for structural or industrial needs.

- Q:Can aluminum sheets be used for food processing equipment?

- Yes, aluminum sheets can be used for food processing equipment. Aluminum is a widely used material in the food industry due to its excellent properties such as corrosion resistance, lightweight, and ability to conduct heat. It is commonly used in the construction of food processing equipment like mixing tanks, conveyors, and food storage containers.

- Q:6061-T6 can aluminum sheets be bent?

- It can be bent, but the hardness of T6 series is higher, and the edges of the sheets are easy to wrinkle or split

- Q:Can aluminum sheets be bent or formed without cracking or breaking?

- Yes, aluminum sheets can be bent or formed without cracking or breaking, as long as proper techniques such as annealing and using appropriate tooling are employed.

- Q:Are aluminum sheets suitable for use in cryogenic environments?

- Yes, aluminum sheets are suitable for use in cryogenic environments. Aluminum has excellent thermal conductivity and low density, making it an ideal material for cryogenic applications. It can withstand extremely low temperatures without losing its structural integrity or experiencing significant thermal expansion. Additionally, aluminum has good corrosion resistance and can be easily fabricated into various shapes and sizes. These properties make aluminum sheets commonly used in cryogenic systems, such as cryostats, superconducting magnets, and liquid nitrogen storage tanks.

- Q:doesn't particularly need to be welding but i need to make an air tight permanent seal around 2 very thin sheets of aluminium (like .02 inches thick) i was thinking .02 inch 5052 aluminum because its the thinnest i can find but am obviously up for suggestions.

- May be you can use spot welding.But may be that would not give you an air tight permanent seal.So,you can go for Hydraulic pressing as in FERRARI 599 GTO's exhaust.(QUITE EXPENSIVE to be done at personal level)

- Q:It is a club aluminium dutch oven from the 50's. It is discolored on the interior and has baked on dirt on the exterior. The exterior has a textured surface which makes cleaning more difficult. I tried baking soda and water paste, but it did not budge it!

- try oven cleaner

- Q:What are the different types of protective films available for aluminum sheets?

- There are several different types of protective films available for aluminum sheets, each offering unique features and benefits. Some common types include: 1. Polyethylene (PE) film: PE film is a popular choice for protecting aluminum sheets due to its versatility and cost-effectiveness. It provides a temporary barrier against scratches, dust, dirt, and moisture during storage, transportation, and fabrication processes. PE film can be easily applied and removed without leaving any residue or damaging the surface of the aluminum sheet. 2. Polyvinyl Chloride (PVC) film: PVC film is another commonly used protective film for aluminum sheets. It offers excellent protection against scratches, abrasions, and UV rays. PVC film is known for its durability, making it suitable for long-term applications. It is available in various thicknesses and can be customized to meet specific requirements. 3. Polyolefin film: Polyolefin film is a type of shrink film that provides all-around protection for aluminum sheets. It is highly resistant to punctures, tears, and moisture. Polyolefin film can be heat-shrunk onto the aluminum surface, creating a tight seal and preventing any damage during handling, storage, or transit. 4. Polyester film: Polyester film is a high-performance protective film that offers superior resistance against chemicals, solvents, and extreme temperatures. It provides an excellent barrier against moisture, preventing corrosion and oxidation of the aluminum sheet. Polyester film is often used in demanding applications where maximum protection is required. 5. Adhesive-backed film: Adhesive-backed films are self-adhesive protective films that can be easily applied and securely bonded to aluminum sheets. They provide a temporary protective layer against scratches, stains, and other surface damages. Adhesive-backed films are available in different adhesive strengths, allowing for easy removal without leaving any residue or damaging the aluminum surface. It is important to select the appropriate type of protective film based on the specific requirements and conditions in which the aluminum sheets will be used.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finished Aluminium Coils for Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords