Mill Finish DC Aluminium Sheet for Mould Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Mill Finish DC Aluminium Sheet for Mould Making

l Product Specification:

Alloy No | 6061 6063 6082 |

Temper | T3-T6 |

Specification | Thickness: 0.2mm-350mm |

Width: 300mm-2500mm | |

Color | Nature color |

Treatment | Hot rolled |

Package | Standard seaworthy export packing: wooden pallets with plastics protection |

Surface treatment | Mill finish,coated,polished,embossed, etc |

Features | High weather resistance \anti scratch anti-corrosion \ easy processing installation\ high brightness |

Application | Mould making |

Payment terms | L/C OR T/T |

Delivery time | Within 20 days |

MOQ | 2.5 metric tons |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirement

Delivery detail: about 20 days from received oiginal L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

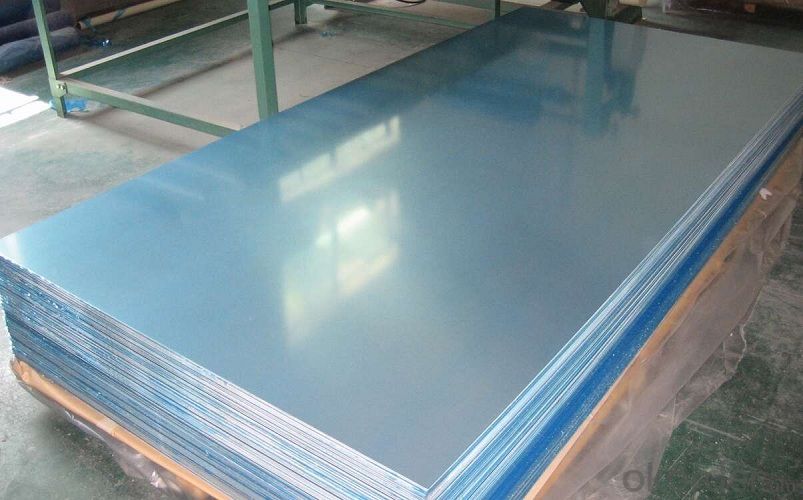

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q:Are aluminum sheets suitable for automotive wheels?

- Automotive wheels can indeed be made from aluminum sheets. Aluminum, being both lightweight and strong, offers numerous advantages in the automotive industry. The incorporation of aluminum wheels can notably decrease the weight that is not supported by the suspension, thereby enhancing fuel efficiency and maneuverability. Moreover, aluminum possesses exceptional heat dissipation properties, which effectively prevent the brakes from overheating. Not to mention, aluminum wheels exude a sleek and stylish appearance, making them highly favored by car enthusiasts. It is worth mentioning, however, that not all aluminum sheets are suitable for automotive wheels. It is imperative to choose aluminum sheets of superior quality that have been specifically engineered to meet the stringent requirements of strength, durability, and heat resistance for automotive wheel applications.

- Q:What is the typical elongation of aluminum sheets?

- The typical elongation of aluminum sheets ranges from 5% to 30%, depending on the specific alloy and temper.

- Q:Where is the difference between the 5052 aluminum plate and the 1060 Aluminum plate?

- Composition and properties are not the same, first of all, 5052 belong to the alloy (aluminum magnesium) aluminum, aluminum content of about 95%, the magnesium content of about 4%, there are some other trace metals, 1060 pure aluminum (aluminum content of 99.6%, the balance of other metal elements); followed by mechanical propertiesTwo aluminum in the same state, 5052 to 1060 in hardness, elongation, tensile strength and so on are not the same. Specific depends on what state (H14, H32, H24, O state, etc.); finally, because the price of different components determine the price is different, the price is usually 5052 higher than 1060.

- Q:Can aluminum sheet be used for signage?

- Yes, aluminum sheet can be used for signage due to its durability, lightweight nature, and resistance to corrosion, making it a popular choice for a wide range of indoor and outdoor signage applications.

- Q:What are the different methods of surface coating aluminum sheets?

- Aluminum sheets can be coated using various methods, each with its own advantages and applications. Anodizing, powder coating, and painting are the most commonly used methods. Anodizing is a process that creates a strong and corrosion-resistant layer on the surface of aluminum sheets. By immersing the sheet in an electrolyte solution and passing an electric current through it, an oxide layer is formed. This layer can be dyed to achieve different colors. Anodized aluminum sheets are widely used in architecture, automotive, and aerospace industries. Powder coating is another popular method where dry powder is electrostatically applied onto the surface of aluminum sheets. The sheet is then heated, causing the powder to melt and form a durable protective coating. Powder coating provides excellent resistance to chemicals, UV rays, and harsh weather conditions. It finds applications in construction, automotive, and electronics industries. Painting is a traditional method where liquid paint is applied onto the surface of aluminum sheets using brushes, rollers, or spray guns. This method allows for a wide range of colors and finishes. Painted aluminum sheets are commonly used in signage, architectural facades, and interior design where aesthetics and customization are important. Other methods of coating aluminum sheets include cladding, laminating, and adhesive bonding. Cladding involves attaching a different material, such as stainless steel or copper, to the surface of aluminum sheets. Laminating involves bonding a protective film to enhance durability and appearance. Adhesive bonding involves applying a layer of adhesive and then bonding a different material or coating. Ultimately, the choice of surface coating method for aluminum sheets depends on specific requirements such as durability, aesthetics, corrosion resistance, and cost for each application.

- Q:Can aluminum sheets be used in electrical applications?

- Aluminum sheets have the capability to be employed in electrical applications. Due to its adeptness in conducting electricity, aluminum is frequently utilized in diverse electrical components and applications. In power transmission lines, bus bars, and electrical enclosures, aluminum sheets are frequently employed as conductive materials. Moreover, their exceptional thermal conductivity properties make them valuable in the production of capacitors, transformers, and heat sinks. Furthermore, aluminum sheets are lightweight and resistant to corrosion, rendering them appropriate for electrical applications where weight and durability are crucial considerations.

- Q:What advantages does the ceramic panel curtain wall have compared with the aluminum sheet and stone curtain wall?

- Metal plate curtain wall deformation resistance is poor, the plate strength and steel are not high enough, waterproof sealing performance is not good enough, easy to fade, deformation, also can cause light pollution. Construction and installation technical requirements are relatively high.Stone curtain wall is now used most, but more stereotyped, and negative news constantly, stone fell, heavy stones, high-rise building exterior wall of high risk, poor fire performance.

- Q:What is aluminium plate for?

- Two outdoor and indoor, outdoor curtain wall decoration, indoor ceiling (such as aluminum pinch plate, aluminum grille, aluminum hanging tablets, etc.), color diversity, but also can be made imitation wood grain, imitation marble and other colors, widely used

- Q:Can 101 aluminum sheets be used in HVAC systems?

- Certainly, HVAC systems can utilize 101 aluminum sheets. Due to its exceptional thermal conductivity, resistance to corrosion, and lightweight attributes, aluminum is frequently employed in HVAC systems. The 101 aluminum alloy, a widely utilized grade, offers commendable strength and ductility, rendering it suitable for HVAC applications. It is commonly employed in the manufacturing of ducts, air handlers, heat exchangers, and various other components within HVAC systems. Moreover, aluminum sheets are highly malleable, allowing them to be easily molded and shaped in accordance with the specific demands of the HVAC system.

- Q:Can aluminum sheets be textured or patterned?

- Indeed, it is possible to texture or pattern aluminum sheets. Numerous techniques exist for achieving desired textures or patterns on aluminum sheets, including embossing, engraving, or etching. These methods entail modifying the surface of the aluminum sheet to achieve the desired texture or pattern. Furthermore, aluminum sheets can also be coated or painted with various finishes or colors to attain a specific textured or patterned appearance. In summary, by employing appropriate techniques and processes, aluminum sheets can be extensively transformed and personalized to possess a diverse array of textures and patterns.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finish DC Aluminium Sheet for Mould Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords