Mill Finish Aluminum Sheet AA1100 H14 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Mill Finish Aluminum Sheet AA1100 H14 for Curtain Wall

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finish Aluminum Sheet AA1100 H14 for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Sheet AA1100 H14 for Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

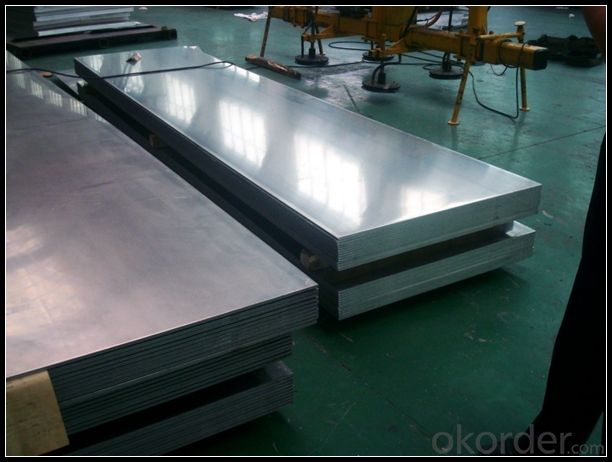

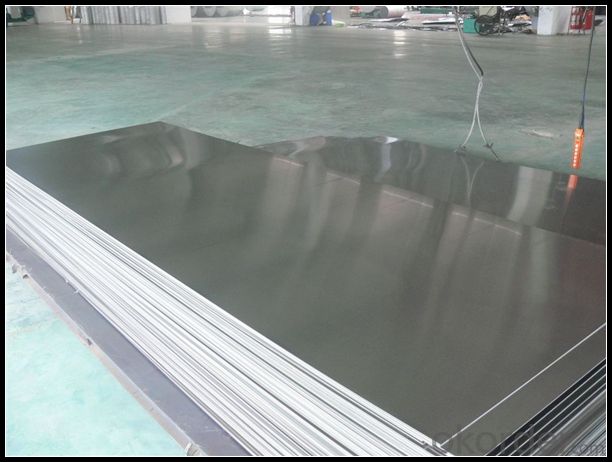

5. Image of Mill Finish Aluminum Sheet AA1100 H14 for Curtain Wall

6. Package and shipping of Mill Finish Aluminum Sheet AA1100 H14 for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Are aluminum sheets suitable for use in food processing or packaging industries?

- Yes, aluminum sheets are suitable for use in food processing or packaging industries. Aluminum is a widely used material in the food industry due to its excellent properties such as being lightweight, corrosion-resistant, and having good thermal conductivity. It is also impermeable to moisture, oxygen, and light, which helps to preserve the quality and freshness of food products. Additionally, aluminum sheets can be easily formed into various shapes and sizes, making them versatile for different packaging requirements.

- Q:i've been looking at stove top espresso coffee makers and they are all made of either aluminum or stainless steel. so i wonder is one metal any better than the other as far as coffee makers go? i thought before i actually buy one i'd like to hear from you - do you have a stove top espresso maker? what metal is it and what do you think of it? looking forward to reading your thoughts - thanks everyone!cheers!

- It's actually a lot better

- Q:What are the typical thicknesses of aluminum sheets?

- The typical thicknesses of aluminum sheets can vary depending on the specific application and industry requirements. However, some common standard thicknesses for aluminum sheets are 0.025", 0.032", 0.040", 0.050", 0.063", 0.080", 0.090", 0.100", 0.125", and 0.190" inches. These thicknesses are often used in various industries such as construction, automotive, aerospace, and manufacturing. It is important to note that aluminum sheets can also be customized to meet specific thickness requirements for specialized applications.

- Q:Are aluminum sheets suitable for use in automotive or aerospace industries?

- Yes, aluminum sheets are suitable for use in both the automotive and aerospace industries. Aluminum is widely used in these industries due to its lightweight yet strong properties, corrosion resistance, and good thermal and electrical conductivity. It is commonly used in the construction of vehicle bodies, aircraft frames, and various aerospace components.

- Q:Are 101 aluminum sheets suitable for decorative purposes?

- Yes, 101 aluminum sheets are suitable for decorative purposes. These sheets are made of high-quality aluminum alloy, which provides a sleek and polished appearance. They have excellent corrosion resistance and are easy to clean, making them ideal for use in decorative applications. Additionally, 101 aluminum sheets can be easily cut and shaped, allowing for creative designs and customization. Whether it's for interior or exterior decoration, these sheets can be used for various purposes such as wall cladding, signage, furniture accents, and more. With their durability and aesthetic appeal, 101 aluminum sheets are a great choice for adding a touch of elegance to any space.

- Q:Everyone said that the pre roll coated aluminum plate, what is pre roll coating?

- Beforehand, beforehand, mean,Roll coating is a paint coating process, relative to spraying, such as powder, wall coating, coating or roller coatingThe coating is applied to the surface of the aluminum sheet by a roller or steel roller. Roll coating

- Q:Aluminum siding is essentially maintenence-free, extremelydurable, and is a great insulator, even better than brick. Brickleaks air through the mortar between the bricks, especially in olderhouses that need tuckpointing. My question is, do you feel sidingstill has a declasse connotation, or is it getting more acceptableas the years go on?

- Brick is certainly the most durable if taken care of properly. My second choice is aluminum siding, which is far more durable than vinyl siding any day. Vinyl is simply more affordable, which is why most home have it these days - whoever decided that aluminum siding declasses a home, is full of malarky.

- Q:hi my house is wired with aluminum wire and we have this light that has been changed 6 times because originally there was a cheap builders light up there that got replaced with a ceiling fan but the ceiling fan was replaced a couple of times since the remote never worked properly on any of the cieling fans so finally we replaced the cieling fan with just a normal light but now the socket got cracked on the new light by accident. The problem is im wondering if it is safe to put another light up because i have heard aluminum wire breaks easy and the wires have been moved around alot. But if i dont replace the light i wont have a light. We also use the correct wire nuts and anti oxidant on the connections. Also when the 4 cieling fans that had been put up were wired correctly since i have put up many cieling fans up without remotes before. Also Is there a certain number of times aluminum or copper wire can be bent with out having to worry about a fire happening or the wire breaking.

- OK. the first thing is that you can connect copper to aluminum. They make wire that is called copper clad aluminum and is exactly what it sounds like, but you don't have to install that. So if you want to install a junction box just make sure that it remains exposed and that you secure the wire within 12 inches of the box. About your light. I would simply put up another fixture, just make a visual inspection of the wire. if it is all roughly the same shade then it is most likely still fine. The only damage that is done by replacing a fixture to much is to the wire that is inside of the box and if something happens to that it will not start a fire, the light simply won't work.

- Q:Also what are some intersting facts about Aluminum? (the element) thanks 2 any 1 who answers =)

- Aluminum is a versatile material with vast applications in engineering, aerospace and automotive industries. Some of its desirable properties include lightweight (relative to steel) and high strength. The metal is however rarely used in its pure form, it is often alloyed with other elements such as Mg, Manganese, chromium, Titanium to fine tune its mechanical, chemical and or physical properties and tailor it to specific applications. However, in some applications other materials are preferred, for example, Magnesium, due to its higher strength to weight ratio is increasingly replacing Al in transmission casing of automobiles. Also, Compacted Graphite cast Iron is preferred in engine blocks because of its superior strength at high tempreatures, dimensional stability and wear resistance. Auto engines work at very tempreatures and alloys that are capable of withstanding high pressures while maintaining stability are critical. CGCI performs better than Al in this situation. Al alloys remains an important engineering materials though.

- Q:I'm buying a sword this afternoon for about 100 bucks i'm using it mainly to take pictures of and hang it on my wall. I looked up tips about buying swords and i think the sword i want is made out of aluminum. Could i use this sword as protection on an armed robber who would break into my house?

- a) yes it can be used for self defense, but it's going to be a stabbing weapon. Aluminum swords are garbage quality and are simply unable to hold a cutting edge, and b) There have been legal cases where people using stabbing weapons in perfectly justifiable self defense have been charged with manslaughter. The rationale was that if you're strong enough to kill someone with a stabbing weapon then you're strong enough to defend yourself (and not kill someone) without needing to use a stabbing weapon. This is crap that only a soft on crime liberal prosecutor could dream up. If I were you, I'd keep the aluminum sword on the wall, and if you can't afford a shotgun, then get a baseball bat. Those things will break bones, smash skulls, and otherwise bring an attack to an immediate end and since it's common sports equipment you'll look like you grabbed the first thing in desperation rather than you wanted to practice your Samurai skills the first chance you got. Just my .02 cents...

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finish Aluminum Sheet AA1100 H14 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords