Mill Finish Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Mill Finish Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

1.Structure of Mill Finish Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Mill Finish Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

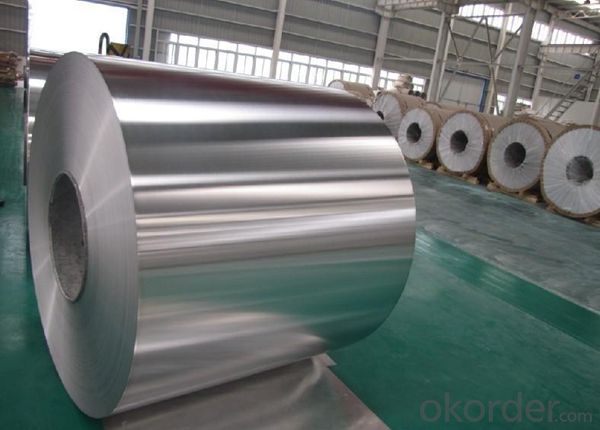

3. Mill Finish Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX Images

4.Specification of Mill Finish Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

Alloy Number | AA5XXX 1XXX 3XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Mill Finish Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:What is the impact of alloy purity on the performance of aluminum coils?

- The performance of aluminum coils is greatly influenced by the purity of the alloys used. Alloy purity refers to the absence of impurities or contaminants within the aluminum material. The mechanical strength of the aluminum coils is one important factor that is affected by alloy purity. Impurities in the alloy can weaken the overall structure and decrease its tensile strength. Alloys with higher purity tend to have better mechanical properties, enabling the coils to withstand higher loads and stresses without deforming or failing. Alloy purity also plays a role in the electrical conductivity of aluminum coils. Impurities like iron, copper, or silicon can increase electrical resistance, resulting in energy losses during transmission. Alloys with higher purity have lower electrical resistivity, ensuring efficient power transmission and minimizing energy loss. Corrosion resistance is another critical aspect influenced by alloy purity in aluminum coils. Impurities can act as catalysts for corrosion, reducing the coil's lifespan and durability. Alloys with higher purity exhibit improved resistance to corrosion, making them suitable for various applications, especially those in corrosive environments. Furthermore, alloy purity affects the thermal conductivity of aluminum coils. Impurities hinder the efficient transfer of heat, reducing overall thermal performance. Alloys with higher purity have better thermal conductivity, allowing for effective heat dissipation and improved thermal management in applications like heat exchangers or cooling systems. To summarize, the impact of alloy purity on the performance of aluminum coils is significant. Alloys with higher purity offer improved mechanical strength, electrical conductivity, corrosion resistance, and thermal conductivity. Therefore, selecting alloys with higher levels of purity is crucial to ensure optimal performance and longevity of aluminum coils in various applications.

- Q:Can aluminum coils be used for structural purposes?

- No, aluminum coils are typically not used for structural purposes as they lack the necessary strength and rigidity required for structural applications.

- Q:Are there any certifications or standards for aluminum coils?

- Yes, there are certifications and standards for aluminum coils. The most widely recognized certification for aluminum coils is the Aluminum Association's Certification Program. This program ensures that the aluminum coils meet specific quality and performance standards set by the association. Additionally, there are various standards and specifications set by organizations such as ASTM International, the American Society of Mechanical Engineers (ASME), and the International Organization for Standardization (ISO) that govern the manufacturing and performance of aluminum coils. These standards cover aspects such as the chemical composition, mechanical properties, and dimensional tolerances of the coils, ensuring that they meet the required industry standards.

- Q:What can I get easily at Home Depot that will successfully bond rubber to aluminum?? I have tried several things with no success! Surely, there must be some sort of construction adhesive to do the job.Thanks!

- Several okorder /

- Q:Can aluminum coils be customized to specific requirements?

- Yes, aluminum coils can be customized to specific requirements. The customization process involves adjusting the dimensions, thickness, alloy composition, and surface finish of the coils to meet the specific needs of different industries and applications.

- Q:Well, we've got the existing old school 7 layers of peeling yucky painted siding and we're trying to weigh our options. So here's my questions:1) Is it cost effective to replace Aluminum with Vinyl?2) Is Vinyl truly as costly as we keep hearing? **Home is small 1,100 sq.ft with a 2.5 car Garage**3) Is painting this existing siding a wise choice since the current paint job on it looks terrible? We just need to make it more a home, right now it's gorgeously all new and redone inside and on the outside it still resembles the day we bought it in forclosure. Aside from my green grass I busted my butt on last summer.Please advise.

- Vinyl is final. Change your siding. It will cost a little more now, but you will save a lot in the long run. If it buckles like one of your other answers, It means that it was installed improperly. Vinyl should not be nailed to tight. It needs to expand and contract with the temperature changes.

- Q:Are aluminum coils suitable for marine applications?

- Yes, aluminum coils are suitable for marine applications due to their excellent corrosion resistance properties in saltwater environments.

- Q:What is the typical coefficient of thermal expansion for aluminum coils?

- The typical coefficient of thermal expansion for aluminum coils is approximately 23 x 10^-6 per degree Celsius. This means that for every degree Celsius increase in temperature, the length of the aluminum coil will expand by 23 parts per million. The coefficient of thermal expansion is an important factor to consider when designing and working with aluminum coils, as it affects their dimensional stability and can cause thermal stresses in the material when exposed to temperature changes.

- Q:How are aluminum coils joined in a continuous process?

- Aluminum coils are typically joined in a continuous process through a technique called welding, specifically a process known as continuous welding or continuous coil welding. This involves feeding the adjacent ends of the coils through a welding machine, which uses heat and pressure to fuse the metal together. This continuous welding process ensures a seamless and strong joint between the aluminum coils, allowing for efficient and uninterrupted production.

- Q:What are the standard tolerance levels for aluminum coils?

- The standard tolerance levels for aluminum coils can vary depending on the specific requirements and industry standards. However, common tolerance levels for aluminum coils typically range from +/- 0.003 to 0.020 inches for thickness, and +/- 0.005 to 0.100 inches for width. It is important to consult the appropriate industry standards and specifications to determine the specific tolerance levels needed for a particular application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finish Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords