Mill Finish Aluminium Sheet Alloy AA1060 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Mill Finish Aluminium Sheet Alloy AA1060 for Curtain Wall

Alloy Number | AA1xxx 3xxx 5xxx |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Mill Finish Aluminium Sheet Alloy AA1060 for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Sheet Alloy AA1060 for Curtain Wall

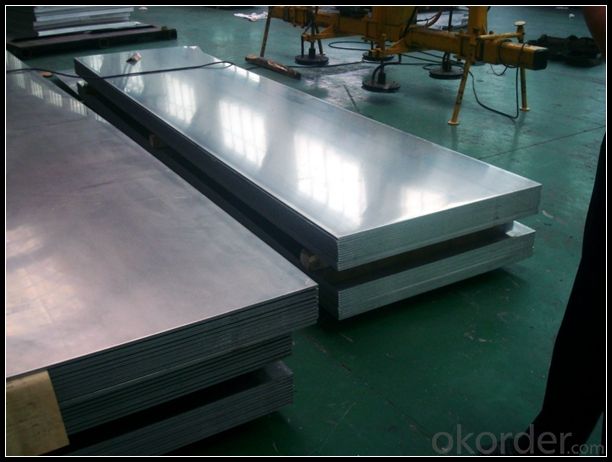

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

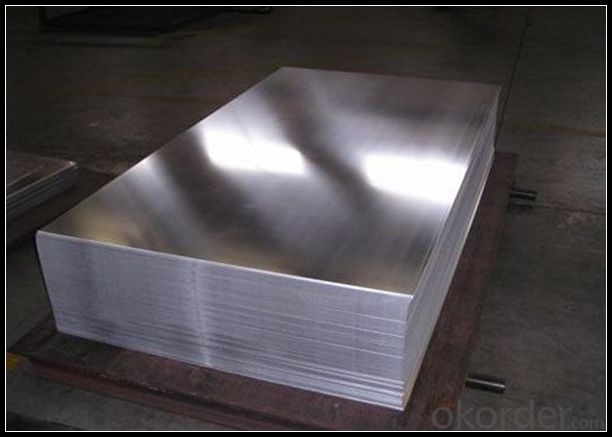

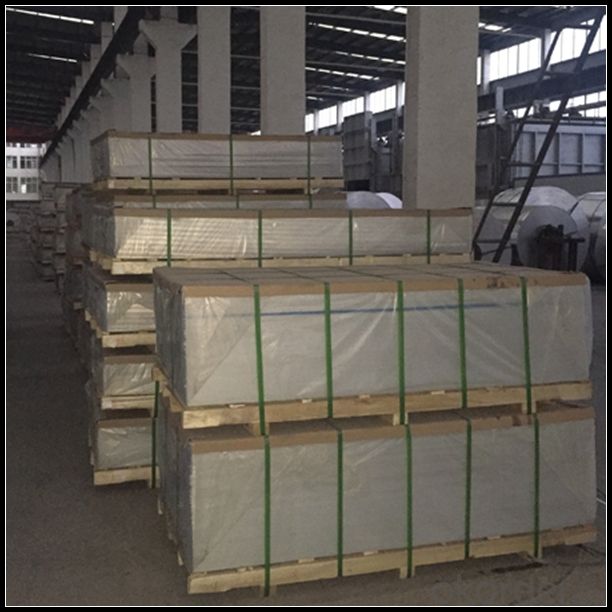

5. Image of Mill Finish Aluminium Sheet Alloy AA1060 for Curtain Wall

6. Package and shipping of Mill Finish Aluminium Sheet Alloy AA1060 for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:2mm aluminum welding with oxygen welding or argon arc welding good?

- Before welding need cleaning with acetone wire and base metal surface oil and oxide layer, according to welding tungsten diameter, filler wire diameter selection of appropriate welding parameters (base current, peak current, pulse width, pulse duration, pulse frequency, duty ratio, etc.).Oxygen acetylene (or oxygen propane) flame welding, flame welding due to large heating area, directly lead to weld coarse grains, degree of weld oxidation is lower than that of AC TIG welding effect. The weld strength and mechanical properties are lower.

- Q:Are aluminum sheets magnetic?

- Aluminum sheets lack magnetic properties and do not exhibit any attraction or interaction with magnets. This is due to the absence of magnetic elements like iron or nickel in aluminum, making it a non-magnetic metal.

- Q:Are aluminum sheets suitable for chemical storage applications?

- Yes, aluminum sheets are suitable for chemical storage applications. Aluminum is known for its excellent corrosion resistance, making it ideal for storing a wide range of chemicals. It forms a naturally occurring oxide layer on its surface, which provides a protective barrier against moisture and chemicals. Additionally, aluminum sheets are lightweight and easy to handle, making them convenient for storage purposes. However, it is essential to consider the specific chemical being stored and consult with experts to ensure compatibility with aluminum. Some highly corrosive or reactive chemicals may require alternative storage materials.

- Q:What is the difference between aluminum plate and aluminum-plastic plate?

- Aluminum sheet: aluminum or aluminum alloy (strip) as the base material, processed by molding and surface protection and decorative coating or anodized film of single aluminum sheet (sheet) called aluminum veneer. Aluminum veneer is widely used for architectural decoration called architectural aluminum veneer, the implementation of GB/T23443-2009 standards.Two, aluminum plate: the full name is called aluminum-plastic composite board. The utility model relates to a three layer composite decorative board with plastic as core material, aluminum sheet (sheet) on both sides, and protective coating and decorative coating on the surface of aluminum. There are two kinds of aluminum-plastic panels, one is common decorative aluminum plate, the implementation of GB/T22412-2008; one kind of building curtain wall with aluminum plate, the implementation of GB/T17748-2008.The difference between the three, aluminum single plate and aluminum plate: 1, aluminum veneer is a single plate, only raw materials, namely, aluminum strip and aluminum plate; three layer composite plate, the two sides for aluminum (film) commonly known as aluminum substrate or aluminum substrate, the middle layer is a plastic commonly known as plastic core material, raw materials there are two kinds, one is aluminum plate, two plastic core material; 3, aluminum veneer thickness is generally of no limit, if too thick aluminum plate aluminum base composite is not strong, at present in the world within the scope of the general requirements of aluminum substrate thickness limit of not more than 1mm. The above is the main difference between the aluminum sheet and the aluminum-plastic plate. Upstairs answer, some are wrong, for example, "2", the quality is different: because aluminum plate is less than aluminum plate, aluminum layer, so the aluminum plate than aluminum plate quality must be worse." Please survey.

- Q:Can aluminum sheets be used for food processing equipment?

- Yes, aluminum sheets can be used for food processing equipment. Aluminum is a widely used material in the food industry due to its excellent properties such as corrosion resistance, lightweight, and ability to conduct heat. It is commonly used in the construction of food processing equipment like mixing tanks, conveyors, and food storage containers.

- Q:how to make aluminum products bright? How to polish or clean the products punch formed by 0.3mm aluminum sheet?

- you can try to grind it with magnetic grinder.

- Q:Aren't metals in general (and aluminium in particular) excellent heat conductors?

- Yes aluminium is a good heat conductor, which is why it is used as a heatsink to dissipate heat from electronic components like the CPU in you laptop. The idea of the aluminium stand for your laptop is to raise it up from the desktop surface, allowing air to pass between the gap and extract the heat from the aluminium stand as your laptop heats up with use.

- Q:Can the aluminum sheets be used for manufacturing electronic heat sinks?

- Yes, aluminum sheets can be used for manufacturing electronic heat sinks. Aluminum is a popular choice for heat sink material due to its excellent thermal conductivity and lightweight properties. It efficiently transfers heat away from electronic components, helping to dissipate and manage heat generated during operation. Aluminum sheets can be easily formed and shaped into the desired heat sink design, providing effective cooling for electronic devices.

- Q:How do aluminum sheets handle extreme temperatures?

- The exceptional ability of aluminum sheets to handle extreme temperatures is widely recognized. This is primarily due to their high thermal conductivity, which enables them to effectively dissipate heat. As a result, they are suitable for applications involving high temperatures. Aluminum, with a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), can withstand a wide range of extreme temperatures without compromising its structural integrity. When exposed to intense heat, aluminum sheets do not easily deform or warp. Consequently, they are ideal for use in environments with high temperatures, such as industrial furnaces, automotive engines, and aerospace applications. Furthermore, aluminum has a low coefficient of thermal expansion, meaning it expands and contracts minimally when subjected to temperature variations. This significantly reduces the risk of cracking or structural damage. On the contrary, aluminum also performs exceptionally well in extremely cold temperatures. It remains durable and retains its strength even in freezing conditions. This makes aluminum sheets suitable for cryogenic applications, including the construction of liquid natural gas tanks or aerospace components that operate in low-temperature environments. In conclusion, aluminum sheets excel in handling extreme temperatures due to their high thermal conductivity, low coefficient of thermal expansion, and excellent structural integrity. Whether subjected to intense heat or extreme cold, aluminum sheets remain stable and reliable, making them the preferred choice in various industries.

- Q:what's the difference between the knocking voice of aluminum sheet and stainless steel?

- The voice of aluminum sheet is toneless, and the voice of stanless steel is more crisp.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finish Aluminium Sheet Alloy AA1060 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords