Mill Finish Aluminium Sheet AA1100 H14 for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Mill Finish Aluminium Sheet AA1100 H14 for Building

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finish Aluminium Sheet AA1100 H14 for Building

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Sheet AA1100 H14 for Building

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

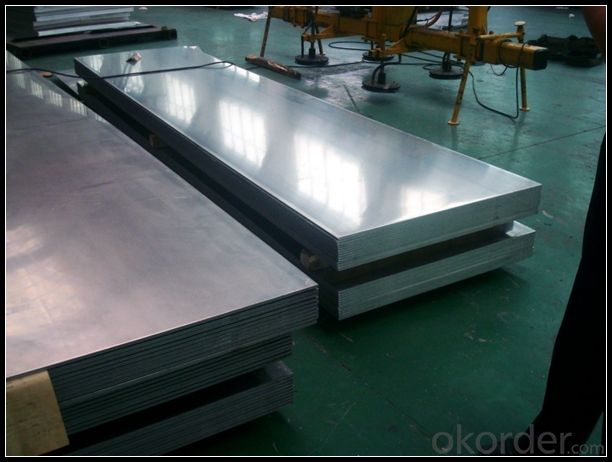

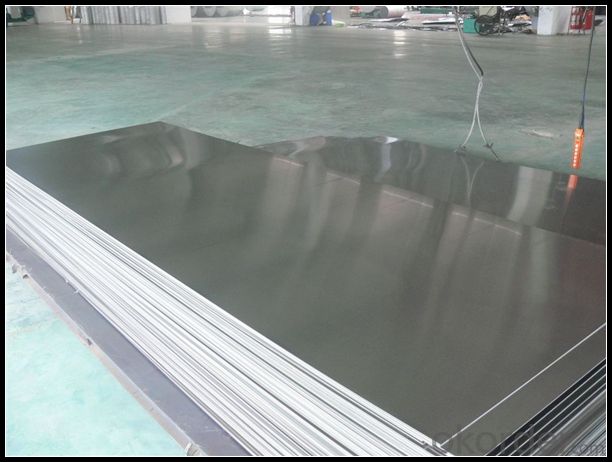

5. Image of Mill Finish Aluminium Sheet AA1100 H14 for Building

6. Package and shipping of Mill Finish Aluminium Sheet AA1100 H14 for Building

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum sheet be used for automotive heat shields?

- Yes, aluminum sheet can be used for automotive heat shields. It is a commonly used material due to its high thermal conductivity, lightweight nature, and excellent heat resistance properties.

- Q:How much should I be charged to have aluminum siding installed? I have a two floor single family home which is detached. I also would want new gutters installed and soffets (i think that is what they are called). One company estimated 12k and another said 10K. This would entail just putting the siding over the original siding. Any answers are appreciated.

- You have no say in the matter. The insurance company is paying the contractor to remove and dispose of the old siding. They don't care if the contractor makes a few hundred bucks selling the siding as scrap and neither should you.

- Q:Maybe you didn't know but in the year 2025 the earth's population will be up to 12 billion people, which is double what we have now. And i am doing a project on Aluminum, and I have to know if there is enough AL for this many people in the year 2025. So will there be enough AL in the world to support us all?

- Aluminium is the third most abundant element on earth after oxygen and silicon. I am quite sure that we will not run out of aluminium in the future. Oxygen - or at least pure good quality oxygen - is probably a more worrying scenario.

- Q:A construction worker uses a steel tape to measure the length of an aluminum support column. If the measured length is 17.7 m when the temperature is 21.2°C, what is the measured length when the temperature rises to 35.4°C? (Note: Do not neglect the expansion of the steel tape. Give your answer to three decimal places.)I am really confused... Could someone solve it for me with a step-by-step explanation? Thank you so much.

- Assume linear thermal expansion with constant expansion coefficient. The change of length is given by: ΔL = L?·α·ΔT (L? initial length, α linear thermal expansion coefficient) The overall length of an object as function of temperature is: L= L? + ΔL = (1 + α·ΔT) · L? Consider the measurement at 21.2°C as reference: The aluminum column changes its length to L= (1 + α_aluminum · ΔT) · L? = (1 + 23×10-6 ^C°-1 · (35.4°C - 21.2°C) ) · 17.7m = 17.705m That would be the length measured with a steel tape at reference temperature of 21.2°C. Unfortunately the steel tape expands too. Because the scale increases with the expansion it measures too short. On the expanded tape you read the length L? while the actual length is L. Hence the measured length is: L? = L / (1 + α_steel · ΔT) = 17.705m / (1 + 11×10-6 ^C°-1 · (35.4°C - 21.2°C) ) = 17.003m

- Q:Can aluminum sheet be used for food packaging?

- Yes, aluminum sheet can be used for food packaging.

- Q:I saw some pretty horrific pictures today of bow shooters with their hands impale by pieces of a carbon arrow that broke after being shot. I'm about to get into the archery sport, and I just want to know before I buy my arrows, will it be safer to buy aluminum shaft arrows instead of carbon? People said aluminum ones aren't as strong, but right now I'm more concern with the safety factor. Yes, I do know that I'm suppose to always check carbon arrows for cracks before I shoot them, but we're all human and sometimes people will forget and make mistakes. I just don't want my hand embedded with carbon shrapnel. So should I get carbon or aluminum? Maybe the new full metal jacket ones will be a good compromise?As a side note, my first bow will be a recurve somewhere around the 30-35 lb draw range. Does the power of the bow affect the chances of an arrow breakage?

- Carbon Arrow In Hand

- Q:What is the typical fatigue strength of aluminum sheets?

- The typical fatigue strength of aluminum sheets can vary depending on various factors such as the alloy, heat treatment, thickness, surface condition, and the specific application. However, in general, the fatigue strength of aluminum sheets falls within the range of 50-70% of their ultimate tensile strength.

- Q:I bought a house with aluminum wiring. Its about 1600 square feet. I have not had any problems with the electric but I read all these story's about how terrible aluminum wiring is.. is it worth the cost to replace? Most houses on my street have it also.. they have had no problems.. house was built in 79.How much would it cost to replace? would walls have to come down to do it?

- aluminium wiring was very common in the '70's. there is nothing wrong with this wiring. it would be a lot better to have copper, but in your situation it is ok. to replace the wiring would be very labour intensive, and expensive. they likely wouldn't remove the whole wall and would do most of thee work in the basement and attic, if u have one. rewiring a house is like doing brain surgery in the dark. it is very important, though that u remember if u have any repairs, (ie: changing a recepticle, a switch, or breaker) you use aluminum compatible parts.

- Q:What are the thermal conductivity properties of aluminum sheets?

- Aluminum sheets possess exceptional thermal conductivity characteristics. With a thermal conductivity of approximately 237 Watts per meter-Kelvin (W/mK), aluminum surpasses other commonly used metals like steel or copper in this aspect. Consequently, aluminum sheets excel in the efficient transfer of heat over their surface. Due to its high thermal conductivity, aluminum can swiftly conduct and distribute heat, making it an optimal choice for applications that demand efficient heat transfer, including heat exchangers, cooling systems, and heat sinks. Moreover, aluminum's lightweight nature and resistance to corrosion further enhance its popularity in thermal management applications. In summary, aluminum sheets exhibit outstanding thermal conductivity properties, positioning them as the preferred material in industries that prioritize efficient heat transfer.

- Q:I put the aluminum in copper chloride for an experiment and i was wondering if they had different properites.

- Aluminium is and element. An oxide is the result of a substance reacting with oxygen. The properties are completely different for elements and oxides.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finish Aluminium Sheet AA1100 H14 for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords