Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series

1.Structure of Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

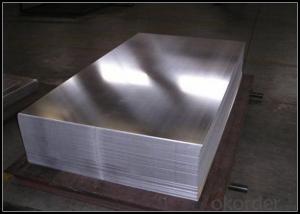

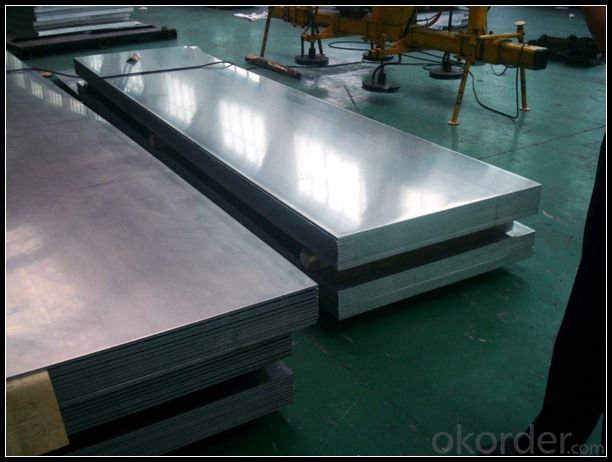

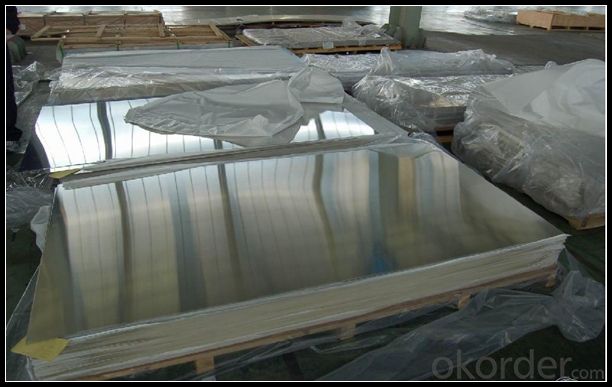

3. Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series Images

4.Specification of Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series

Alloy Number | AA1XXX 3XXX 5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:What is the lifespan of an aluminum sheet?

- The lifespan of an aluminum sheet can vary depending on various factors such as the thickness of the sheet, the quality of the aluminum, and the conditions it is exposed to. However, under normal circumstances, aluminum sheets can last for several decades or even longer if properly maintained and protected from corrosion.

- Q:What is the corrosion resistance of 101 aluminum sheets in saltwater environments?

- The corrosion resistance of 101 aluminum sheets in saltwater environments is generally considered to be quite good. Aluminum is inherently resistant to corrosion, and when exposed to saltwater, it forms a protective oxide layer on its surface that further enhances its resistance to corrosion. This oxide layer acts as a barrier, preventing the saltwater from coming into direct contact with the underlying metal and thus slowing down the corrosion process. However, it is important to note that prolonged exposure to saltwater can still lead to some degree of corrosion over time. Regular maintenance and protective coatings can help to further enhance the corrosion resistance of 101 aluminum sheets in saltwater environments.

- Q:If I were to make an aluminum mold and cover it with a release agent, could I cast aluminum into it? Or would the two parts fuse together? I'm trying to find an alternative to sand casting.Thank you!

- Aluminum okorder /... I use investment lost wax casting.

- Q:Other then pop cans, what else is aluminum that can be recycled?

- all of it.

- Q:What are the different types of patterns available for textured aluminum sheets?

- There are various types of patterns available for textured aluminum sheets, including stucco, diamond, pebble, hammered, and brick patterns. These patterns are created through embossing or rolling processes, providing different textures and visual effects for decorative or functional purposes.

- Q:Can aluminum sheets be anodized in different finishes?

- Yes, aluminum sheets can be anodized in different finishes. Anodizing is a process that creates a protective oxide layer on the surface of aluminum, and this layer can be colored or finished in various ways to achieve different aesthetic and functional results.

- Q:What is the coefficient of thermal expansion of aluminum sheets?

- The coefficient of thermal expansion of aluminum sheets varies depending on the specific alloy used. However, on average, aluminum has a coefficient of thermal expansion of approximately 22 x 10^-6 per degree Celsius (22 x 10^-6/°C). This means that for every degree increase in temperature, the aluminum sheet will expand by 22 x 10^-6 times its original size. It is important to note that this value may slightly differ for different grades and alloys of aluminum.

- Q:I constructed a small hho generator for experimental purposes. I needed to add a cooling condenser to the unit because of a overheating problem. I was using a old heater core from a vehicle, soldered some joints to make some connections. the solution seemed to have eaten the solder I used, which was normal lead free solder used in water pipes. I was going to invest into a trans cooler core which is made of aluminum, but I need to know if the solution will eat up the aluminum. I also thought about using a condenser core from a broken window a/c, which is made of copper tubing. any advise would be very help full

- Aluminum, yes; copper, no. Aluminum is attacked by both acids and bases (it is what is called amphoteric); copper is attacked by neither -- although nitric acid will attack copper by oxidizing it. Solder joints may be attacked by acid, but may be more or less immune to attack by strong bases, depending on what is in the solder.

- Q:Can the aluminum sheets be used for manufacturing automotive radiators?

- Yes, aluminum sheets can be used for manufacturing automotive radiators. Aluminum is a popular choice for automotive radiators due to its lightweight, excellent heat transfer properties, and corrosion resistance. Aluminum sheets can be easily formed into the required shape and size for radiator construction. Additionally, aluminum radiators offer better cooling efficiency compared to traditional copper radiators. Therefore, using aluminum sheets for manufacturing automotive radiators is a viable and advantageous option.

- Q:I've narrowed down my next bike next year to either the cannondale Caad10 Ultegra version or the supersix 105 version, I've heard good things about both bikes, and at this point its gonna be down to preference after I ride it but, is aluminum stronger than carbon or vice versa? Will carbon crack easily or fail catastrophically?

- Ride them both. You will like the aluminum bike, but you will fall in love with the carbon. New carbon frames are very light, stiff, road dampening, and responsive. You have to stand on the pedals only once to know they fly. They have a Cannondale lifetime warranty against cracks. Just a note about the component set. 105 is nice. Ultegra is so smooth. I would pony up for the Ultegra on the carbon frame. There IS a feel difference, not just weight savings. Have fun with either.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords