Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series for ACP Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series for ACP Board

1.Structure of Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series for ACP Board

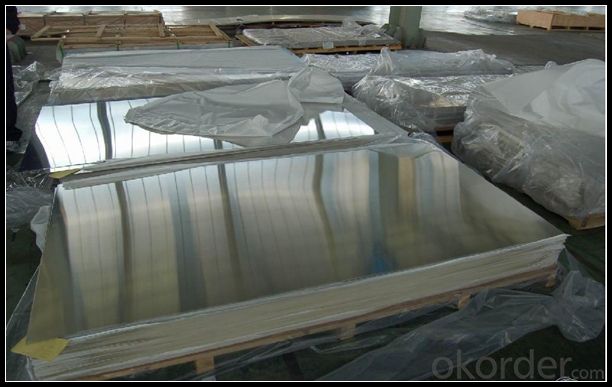

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series for ACP Board

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

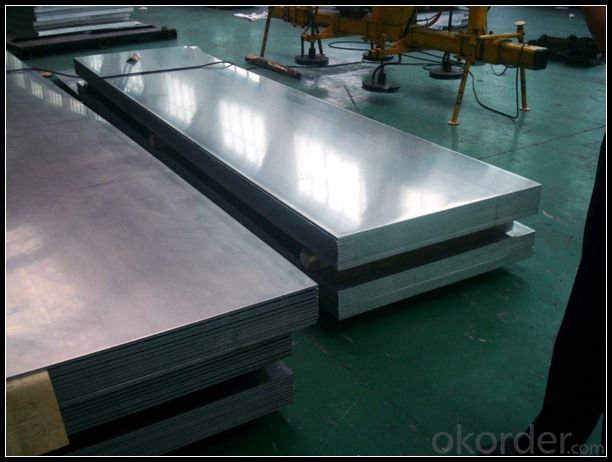

3. Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series for ACP Board Images

4.Specification of Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series for ACP Board

Alloy Number | AA1XXX 3XXX 5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series for ACP Board

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q:What is the typical price range for aluminum sheets?

- The price of aluminum sheets can differ based on several factors, including thickness, grade, size, and quantity required. Typically, aluminum sheets can be priced anywhere between $0.50 and $5 per square foot. Thinner sheets or lower-grade aluminum are generally found at the lower end of the price spectrum, whereas thicker sheets or higher-grade aluminum tend to be on the higher end. It's worth mentioning that market conditions, location, and supplier can also impact prices. Therefore, it is recommended to consult specific suppliers or conduct market research for the most precise and current pricing details.

- Q:Can anyone tell me what to be careful of if you have aluminum wiring in your house. I was told that if the wall gets hot, I need to tighten the screws of the inside switch. Is this true and if I didn't, would it actually cause a fire in the wall. If this is true, how often does it loosen?

- Several answers are very good but the one thing that evrybody failed to mention is each device (switch, recept, fixture, etc.) must be listed to use with AL wire. This is the biggest problem I find. Home owners run out to the local hardware and pick up a new device and do not check the listings. The copper wire pig tail is an option but once again you must use a wire nut that is listed for both AL CU wiring. Most are a dark purple in color. Electrical Inspector

- Q:Could induction heating fuenace be packaged with aluminum foil as insulation material?

- You have thought about it carefully, you can't use aluminum foil.

- Q:Can aluminum sheets be welded or soldered?

- Yes, aluminum sheets can be welded or soldered. However, the process for each differs significantly. Welding aluminum typically involves using a TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding process, which requires a high heat source and a filler material to join the sheets together. The process can be more challenging compared to welding steel due to aluminum's high thermal conductivity and lower melting point. Soldering aluminum, on the other hand, is a process that involves using a low-temperature solder and flux to bond the sheets together. Specialized solders, such as aluminum solder or solder with a high percentage of tin, are typically used. Soldering aluminum is generally less common and more difficult compared to soldering other metals due to aluminum's oxide layer, which can prevent proper adhesion. In summary, while both welding and soldering can be used to join aluminum sheets together, welding is the more commonly used method due to its stronger and more durable results. Soldering aluminum can be more challenging due to the need for specialized solders and the presence of the oxide layer.

- Q:Can the aluminum sheets be used for manufacturing power distribution systems?

- Yes, aluminum sheets can be used for manufacturing power distribution systems. Aluminum has excellent conductivity properties, making it a suitable material for transferring electrical power. Additionally, aluminum sheets are lightweight, corrosion-resistant, and cost-effective, making them a popular choice in the manufacturing of power distribution systems.

- Q:I have a problem when machining aluminium in my machine shop. There are times when the machines aluminium surface turns yellowish (somtimes brown). I do not know what is the main cause of the problem. Is it due to the coolant used?

- Aluminum oxides may appear in different colors depending on hydration states and other variables. Look in a CRC Handbook of Chemistry Physics if available for aluminum compounds and their colors. The colors that you see may also have as much to do with the surface finish as the color of the material on the surface. A microscopically rough surface will appear dark next to a polished surface due to light scattering. I will agree with Ling in principle, but not on details. EDS detection limits on homogeneous samples can be better than 0.1%, although not so good for elements at the light end of the detection range. Current detectors can detect chlorine (a common culprit for aluminum discoloration) at about 0.1%. Your problem with detection and one that Ling has addressed previously may be that a thin film of contamination would not be easily detected by EDS. As Ling suggests, SIMS is a good technique for detecting thin films and low concentrations. The problem with SIMS in this case may be that the detection limits are too good and the technique cannot be quantified. SIMS would detect 2 ppm of chloride and you couldn't tell for sure whether it was 2 ppm, which is probably not an issue here, or 2000 ppm, which would be significant. I would suggest x-ray photoelectron spectroscopy (ESCA or XPS) as an alternative for further study. The technique will analyze thin films (20 A) and detection limits are good enough (about 0.1%). In addition, XPS will give you information about the compounds present, e.g. whether the oxygen is aluminum oxide, aluminum hydroxide, etc. Good Luck.

- Q:Can aluminum sheet be used for food packaging?

- Food packaging can utilize aluminum sheet, which is a popular choice due to its unique properties. This material is lightweight, flexible, and provides excellent protection against moisture, oxygen, and light. Consequently, it helps extend the shelf life of products and maintains their freshness. Aluminum sheet is commonly employed to package beverages, snacks, dairy products, and ready-to-eat meals. Furthermore, it is non-toxic and does not react with food, ensuring safety when in direct contact with consumables. Its versatility allows for easy customization to meet various packaging requirements. Overall, aluminum sheet is widely trusted and used for food packaging due to its durability, protective properties, and adherence to safety standards.

- Q:Can the aluminum sheets be used for manufacturing electrical conductors?

- Yes, aluminum sheets can be used for manufacturing electrical conductors. Aluminum is a highly conductive metal, second only to copper in terms of electrical conductivity. It is widely used in various electrical applications, including power transmission lines, electrical cables, and wiring. Aluminum sheets can be rolled or extruded into different shapes and sizes to suit specific conductor requirements. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective compared to other conductive materials, making it a popular choice for electrical conductor manufacturing.

- Q:Can aluminum sheets be used for bus bodies?

- Yes, aluminum sheets can be used for bus bodies. Aluminum is a lightweight and durable material that is commonly used in the construction of bus bodies. Its high strength-to-weight ratio makes it an ideal choice for bus manufacturers, as it allows for improved fuel efficiency and increased payload capacity. Additionally, aluminum is highly resistant to corrosion, which is beneficial for vehicles that are constantly exposed to various weather conditions. Moreover, aluminum can be easily formed and fabricated, allowing for the creation of complex shapes and designs. Overall, aluminum sheets are a popular choice for bus bodies due to their strength, lightness, corrosion resistance, and versatility.

- Q:A 0.250-g sample of a magnesium-aluminum alloy dissolves completely in an excess of HCl (aq). When the liberated H2 is collected over water at 29 C and 752 torr, the volume is found to be 311 mL. The vapor pressure of water at 29 C is 30.0 torr. What is the mass percentage of aluminum in this alloy?

- This Site Might Help You. RE: Analysis of a Magnesium-Aluminum Alloy? A 0.250-g sample of a magnesium-aluminum alloy dissolves completely in an excess of HCl (aq). When the liberated H2 is collected over water at 29 C and 752 torr, the volume is found to be 311 mL. The vapor pressure of water at 29 C is 30.0 torr. What is the mass percentage of aluminum in this...

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series for ACP Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords