Milk Powder Can Making Machinary for Cans Line

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Description

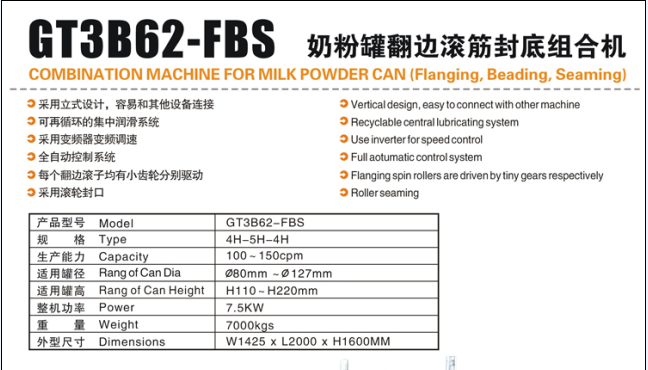

GT3B62-FBS Combination Machine for Milk Powder Can (Flanging, Beading, Seaming)

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

3. Images

4. Specification

1).NC table

Max. speed of arm and clamp: 36m/min

Feed precision: ±0.1mm

Working voltage: ~380V 50HZ

Rated power: 2KW

Outline size (L×W×H)(NC unit): 1740×2340×1045

Weight (NC unit): 1200kg

(2).35T press

Nominal pressure:350KN

Slide block travel distance:70mm

Number of times of travel:120Times/minute

Power:4KW

Outline size (L×W×H)(mm):1660*1340*2360

Weight:5000Kg

For more information:

5.FAQ

A: Do you have some other machinary, such as end making line?

Yes, we do have it.

B. What is the delivery?

It is around 45days, if you need more information, pls contact with us.

C: How about the package?

We use the seaworthy package, which is very safe.

- Q:Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- 5009.101 determination of antimony in polyester resins and their moulding products for food containers and packaging materialsGB 13113 hygienic standard for polyethylene terephthalate moulding articles for food containers and packaging materials

- Q:What's the best place to use the pillow type packing machine?

- This device is now relatively mature technology, but each manufacturer's design is still a little different

- Q:Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- Change a new one, in fact, the knife is very simple, and the ordinary knife is very cheap.If you don't understand, you can ask me

- Q:How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine machine standard price of about 38000, excluding tax, tableware packaging machine is designed for tableware (e.g., chopsticks, bowls, dishes and so on) a modern packaging machinery packaging, this machine is mainly composed of conveyor, packaging machine, output machine, shrink machine, composed of four parts.

- Q:What are the structures of the packaging machinery?

- Is a company engaged in outsourcing clients, packaging, processing, packaging equipment, leasing, services, sales in one of the specialized companiesSales of second-hand packing equipment according to the customer's product features and requirements. Reduce customer purchasing costsAccording to the customer's product characteristics and requirements. Select the best packaging equipment for customers, reduce customer purchasing costsPackaging equipment spare parts sales and maintenance services

- Q:The role of packaging equipment in packaging equipment

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging equipment is playing a more and more important role in the field of packaging. The main functions of packaging equipment are as follows:

- Q:What's the fastest packing machine?

- Depending on the characteristics of your material, the speed is adjustable!

- Q:The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping of objects of different shapes according to their appearance.

- Q:What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q:Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- If you are the original producers, can consider to do the initial stage through the middle of the exporter, first ensure that factory production product quality clearance, production procedures and quality control documents pass, in order to gradually establish its own customer base.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Milk Powder Can Making Machinary for Cans Line

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords