Mild Steel Welding Rod 2.0MM X 300MM Factory Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Welding Rod Description:

E6010 This electrode is used for all position welding using DCRP.

produces a deep penetrating weld and works well on dirty,rusted, or painted metals

E6011 This electrode has the same characteristics of the E6010, but can be used with AC and DC currents.

E6013 This electrode can be used with AC and DC currents.

produces a medium penetrating weld with a superior weld bead appearance.

E7018 This electrode is known as a low hydrogen electrode and can be used with AC or DC.

The coating on the electrode has a low moisture content that reduces the introduction of hydrogen into the weld. lectrode can produce welds of ray quality with medium penetration.

(Note, this electrode must be kept dry. If it gets wet, it must be dried in a rod oven before use.)

2.Main Features of Welding Rod:

1): Durable, strict quality management and control.

2): High precision machining equipments guarantee good quality.

3): Smooth surface. No defects. Continuous skill improvements.

4): Quick delivery, competitive Chinese price. Low MOQ.

5): Our Company is specialized in machining service on precise mechanical parts; we are producing high precision parts for military enterprise

6): We have design team to develop new skill and new products to meet requirements of markets.

7): Good service, when customers have problems during use, we will surely try our best to solve them.

8): High professional employees have good emergency-dealing ability during production.

9): Surface treatment can be nickel, galvanized and painted, or based on the requirements of customers.

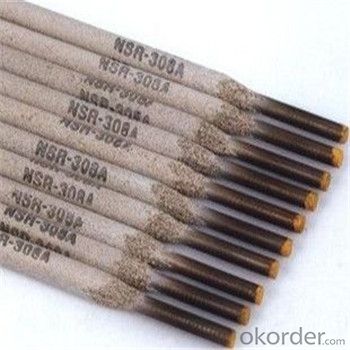

3. Welding Rod Images

4. Welding Rod Specification

Chemical Composition | C | Mn | Si | S | P |

Guarantee Value | ≤0.12 | 0.3-0.6 | ≤0.35 | ≤0.035 | ≤0.040 |

Mechanical Properties of Deposited Metal

Test Item | Rm(MPa) | ReL(Mpa) | A(%) | KV2(J) | KV2(J) |

Guarantee Value | ≥420 | ≥330 | ≥17 | -(normal temperature) | -(0℃) |

Reference Current (AC, DC)

Electrode Diameter(mm) | φ2.0 | φ2.5 | φ3.2 | φ4.0 | φ5.0 |

Length(mm) | 300 | 300(350) | 350 | 400 | 400 |

Welding Current (A) | 40~70 | 55~95 | 80~130 | 120~180 | 160~230 |

V-up, OH | 35~60 | 45~90 | 60~120 | 100~160 | 120~200 |

5.FAQ

Q: How do you ship the Welding Rod?

A: Usually by sea.

Q: Are you a manufacturer?

A: Yes, we have been in providing the professional products in Welding Rod over 10 years.

Q: Can I get the sample?

A: Yes, free samples are prepared for your test.

- Q:Add 100 points to the approved answer before 2, plus 50 at 3. Beg speed

- No, the stainless steel electrode is also the beginning of the E

- Q:What type of welding rod is applied to Q345 steel plate?

- E50 series (E5001~E5048) welding rod can be. To adapt to the requirements and welding of steel used in SMAW electrode, using the intensity principle of E50 series E55 series above right above strength, high cost, comprehensive strength and economic aspects, should choose E50 series of electrode.

- Q:What kind of welding rod is used to weld Mn13 steel plate with ordinary high quality structural steel?

- The basic ingredients are steel, and the liquid flux can be produced by solid light. With the brass welding rod (copper, zinc and tin alloy), the brazing effect can be very good.

- Q:What are the requirements of steel structure for electrode?

- Usually 426 is ok.

- Q:What kinds of welding electrodes are used in the copper tubes for air conditioning? What's the difference?

- There are two kinds, one containing silver, one containing phosphorus. The former is used in a high sulfur environment, and the price is about three times higher than that of the latter

- Q:What welding rod are used for welding of 304 stainless steel pipes?

- 304 electrode, 316 with 316 electrodes, the market has sold

- Q:What does the electrode strip E7108 stand for?

- A welding rod is made up of six parts. For example, CHE507CrNiFe13 can be split into:1. (CH) two letter, the Atlantic product code.2. (E) a letter of electrode type.3. (50) two numbers, deposited metal strength or alloy type.4. (7) a number, type of skin and type of current.5. (CrNi) 1~2 letters, additional alloy elements or electrode characteristics.6. (Fe13) letters + two numbers, nominal efficiency of welding rod.1.CH: the Atlantic product code2. electrode type: (see Table 1)Type of electrode 1E carbon steel welding rod, low alloy steel welding rodL low alloy steel welding rod for low temperatureS chromium nickel austenitic stainless steel electrodeH low alloy steel and stainless steel welding rod for heat resistingK chromium stainless steel electrodeC cast iron welding rodN nickel and nickel alloy welding rodR surfacing electrodeCu copper and copper alloy weldingDeposited metal strength and alloy type: Table 2MarknumberStrength (MPa)Major alloy typesRemarksE 42By 0.2 o = 330 B = 420(S)Mn-SiFifty= 400 = 490= 390 = 490Mn-Si (Ni)Fifty-five= 440 = 540Mn-Si-MoSixty= 490 = 590Mn-Si-Mo (Ni)Seventy= 590 = 690Mn-Si-Mo (Ni)Seventy-five= 640 = 740Mn-Si-MoMn-Si-Ni-MoEighty= 690 = 780Mn-Si-Mo-V-NiEighty-five= 740 = 830Mn-Si-Ni-Mo-V-CrH1 xMo to 0.5%Second digit (x)Represents different grades in the same type2 xMo to 0.5% Cr to 0.5%3 xMo0.5 to 1% Cr to 2%4 xMo to 1% Cr to 2.5%5 xMo to 0.5% Cr to 5%7 xMo to 1% Cr to 9%8 xMo to 1% Cr to 11%R1 xOrdinary room temperature2 xOrdinary room temperature

- Q:Welding method of 506 electrode

- Welding method of 506 electrodeJ506 is a low hydrogen potassium electrode, it is a kind of basic electrode, welding steel structure can be several typical Q235 steel, the tensile strength of E4315 is much larger relative to the common electrode, so the general welding force or by welding steel structure of dynamic load. J506 welding rod diameter ranging from 2.5mm to 6.0mm, can be carried out in all position welding, welding using alternative welding machine. The weld formation after J506 welding is more difficult than that of the acid welding rod. If an electrode is used on the cover of the steel structure, the acid electrode can be used.

- Q:What are the characteristics of welding rod E6010? What are the main points of operation?

- E6010Cellulose electrodeSee the attachment for details.

- Q:What kind of welding rod is MG600? What about the performance? A lot of online sales, but one question is wrong, who knows that home is true?

- Special welding electrode for metal material MG660:Universal wide Cr-Ni high strength welding rod, welding can be almost a variety of commonly used steel, can satisfy the most stringent requirements, such as commonly used in tool steel, die steel, vanadium molybdenum steel, spring steel, spring steel and unknown, is also commonly used in inconsistent interface size steel. Excellent weldability, crack resistance, plasticity and toughness.Our company has, oh, do not worry, ha ha

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mild Steel Welding Rod 2.0MM X 300MM Factory Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches