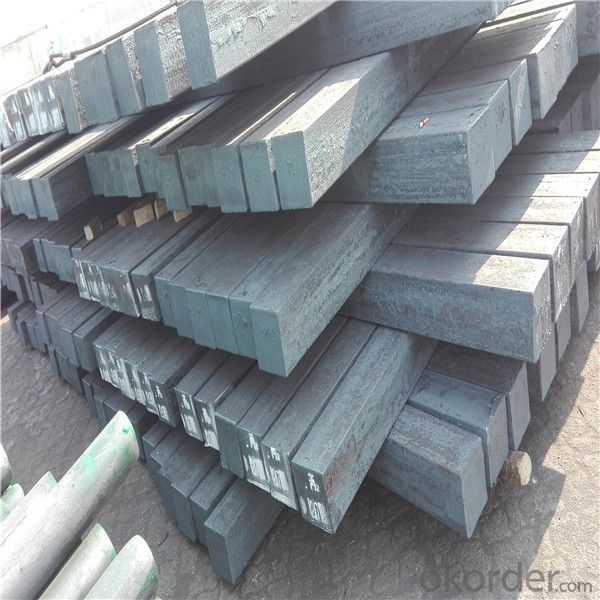

Mild steel billet for sale low price made in china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15542 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Steel billet :

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular

and abnormity of several kinds of, mainly related to the shape of rolled products.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Other Specifications

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q:What is the role of steel billets in the manufacturing of railway wheels?

- Steel billets play a crucial role in the manufacturing of railway wheels. They serve as the primary raw material used to create these wheels. Railway wheels need to be extremely strong, durable, and able to withstand heavy loads, extreme temperatures, and constant wear and tear. Steel billets are first melted down and then shaped into a cylindrical form, which is similar to the final shape of the railway wheel. These billets are then further processed through a series of manufacturing steps, such as hot rolling, forging, and machining, to transform them into the desired shape and dimensions of the railway wheel. The main advantage of using steel billets is their high strength and toughness. Steel is renowned for its excellent mechanical properties, including high tensile strength and hardness. These characteristics are essential for railway wheels, as they need to bear enormous loads and resist deformation under extreme pressures. Moreover, steel billets provide the necessary metallurgical properties required for railway wheels. They can be alloyed with additional elements such as carbon, manganese, and chromium to enhance their strength, hardness, and resistance to corrosion and fatigue. This ensures that the railway wheels maintain their structural integrity and performance over an extended period of time. In summary, steel billets are the starting point in the manufacturing process of railway wheels. They provide the raw material necessary to create robust, durable, and reliable wheels that can withstand the demanding conditions of railway operations. The use of steel billets ensures that railway wheels meet the stringent requirements for safety, performance, and longevity in the transportation industry.

- Q:What are the safety precautions when working with steel billets?

- To maintain a secure working environment and prevent accidents when dealing with steel billets, it is crucial to adhere to specific safety measures. Here are some essential precautions to bear in mind: 1. Personal Protective Equipment (PPE): Ensure that you wear the suitable PPE at all times, including steel-toed boots, safety goggles, gloves, and a hard hat. These items will shield you from potential hazards like falling objects, sparks, and sharp edges. 2. Training and Education: It is vital to provide comprehensive training and education to all workers regarding the handling and usage of steel billets. This encompasses understanding safe operating procedures, material handling techniques, and emergency response protocols. 3. Proper Handling and Storage: Mishandling steel billets can result in injuries due to their weight. Employ appropriate lifting techniques and equipment to prevent strains or sprains. Moreover, store the billets in designated areas, ensuring they are properly stacked and secured to avert accidents caused by falling objects. 4. Fire Safety Precautions: Moving or manipulating steel billets can generate sparks that could ignite flammable materials. Keep the work area clear of debris and flammable substances, and ensure that fire extinguishers are easily accessible. 5. Machine Safety: If utilizing machinery or equipment to handle steel billets, make certain that they undergo regular maintenance, have appropriate safeguards, and are operated by trained individuals. Adhere to all operational instructions and conduct routine safety checks to avoid accidents. 6. Sufficient Ventilation: Working with steel billets may generate fumes and dust, particularly during cutting or welding processes. Implement proper ventilation systems to eliminate these substances from the work area, minimizing the risk of respiratory issues. 7. Emergency Preparedness: Establish a well-defined emergency plan that outlines evacuation procedures, first aid facilities, and communication methods. Train all workers on emergency protocols and ensure they are aware of the locations of safety equipment and emergency exits. Always prioritize safety when working with steel billets. Adhering to these precautions will help minimize accident risks and foster a safe working environment for everyone involved.

- Q:How are steel billets used in the manufacturing of mining equipment?

- Steel billets are indispensable in the production of mining equipment. They are essentially semi-finished steel products that are molded into specific shapes and sizes required for the equipment being manufactured. In the case of mining equipment, steel billets serve as the raw material for various parts like gears, shafts, and structural components. The billets are heated and then subjected to a process called forging. During this process, heavy machinery and high pressure shape and mold the billets into the desired form. The strength and durability of steel make it an ideal material for mining equipment due to the harsh conditions in which these machines operate. Steel billets possess excellent mechanical properties, including high tensile strength and resistance to wear and corrosion. These properties are critical for the equipment to endure heavy loads and abrasive environments encountered in mining operations. Once the steel billets are forged into the required shape, they undergo additional processes such as machining, heat treatment, and surface finishing. These processes ensure that the mining equipment meets the necessary performance criteria and can withstand the rigorous demands of mining operations. Overall, steel billets play a vital role in the manufacturing of mining equipment as they provide a strong and reliable foundation for various components. Their use guarantees that the equipment can endure the extreme conditions of mining operations, ultimately contributing to the efficiency, safety, and productivity of these essential industries.

- Q:How are steel billets used in the production of shipbuilding materials?

- Steel billets play a vital role in shipbuilding materials as they are necessary for producing strong and durable components. Shipbuilding requires materials that can withstand harsh marine conditions, and steel billets fulfill these requirements. To begin with, steel billets are utilized in the production of different types of steel plates. These plates form the basis of shipbuilding materials and are customized according to specific design needs, such as hull plating, bulkheads, decks, and superstructures. Steel billets provide the essential raw material for creating these plates, ensuring they possess the required strength and structural integrity. Furthermore, steel billets are crucial in manufacturing shipbuilding sections and profiles. These sections, including beams, angles, channels, and other structural components, provide support and reinforcement to the ship's structure. Steel billets are heated and shaped through processes like rolling, forging, or extrusion to form these sections. This allows for the creation of custom-shaped sections that seamlessly integrate into the ship's construction. Additionally, steel billets are also used in producing shipbuilding forgings, which are high-strength components requiring exceptional mechanical properties. Forgings are vital for critical ship parts like propeller shafts, rudder components, and engine parts. Steel billets are heated and shaped using forging techniques to create these components, ensuring they possess the necessary strength, toughness, and resistance to fatigue. In conclusion, steel billets are a fundamental raw material extensively used in shipbuilding. They are transformed into various forms such as plates, sections, and forgings, which are then incorporated into the construction of ships. The utilization of steel billets guarantees that shipbuilding materials meet the stringent requirements for strength, durability, and performance in marine environments.

- Q:How are steel billets forged into shape?

- Steel billets are forged into shape through a process known as hot forging. Hot forging involves heating the steel billet to a temperature that allows it to be manipulated easily, usually between 1100 to 1250 degrees Celsius. Once the billet is heated, it is placed on a die, which is a specially designed tool with a cavity that gives the desired shape to the final product. A large mechanical or hydraulic press exerts pressure on the billet, forcing it into the die cavity. This pressure causes the steel to flow and fill the shape of the die, resulting in the desired form of the forged product. The pressure applied during forging can be as high as several thousand tons, depending on the size and complexity of the product. During the forging process, the steel billet undergoes plastic deformation, which rearranges its internal structure and aligns the grains of the metal. This alignment of grains enhances the mechanical properties of the forged product, making it stronger and more durable. After the initial shaping, additional operations such as trimming, piercing, or punching may be performed to achieve the final dimensions and features. These post-forging operations may be done while the steel is still hot or after it has cooled down. Once the desired shape is achieved, the forged product is cooled slowly to relieve any residual stresses and prevent cracking. This cooling process, known as annealing, helps improve the metallurgical properties of the steel and enhances its overall performance. In summary, steel billets are forged into shape through a hot forging process that involves heating the billet, placing it on a die, applying high pressure to force it into the desired shape, and then cooling it down to optimize its mechanical properties. This process allows steel to be transformed into various complex shapes, making it a versatile and widely used material in many industries.

- Q:Difference between medium frequency continuous casting billet and electric furnace continuous casting billet

- In general, the difference between medium frequency furnace steelmaking and electric arc furnace steelmaking:1, intermediate frequency furnace slag can not, so the harmful elements such as P, S and other elements can not be removed, and the electric arc furnace can;2, if not blowing furnace carbon reduction, so C elements cannot be adjusted downward, and the arc furnace can only increase;

- Q:What are the main challenges in the marketing of steel billets?

- The main challenges in the marketing of steel billets can be attributed to several factors. Firstly, one of the major challenges is the highly competitive nature of the steel industry. There are numerous steel manufacturers and suppliers globally, which creates a saturated market. This leads to a constant struggle for market share, as companies need to differentiate themselves from their competitors and maintain a strong presence. Secondly, fluctuations in global demand and supply of steel can pose significant challenges. Steel billets are primarily used as raw material for various industries, including construction, automotive, and manufacturing. Any changes in these industries' demand can directly impact the demand for steel billets. Therefore, marketing strategies need to be adaptable and responsive to market dynamics to ensure a stable customer base. Additionally, pricing is another critical challenge. Steel billets are often subject to price volatility due to factors such as raw material costs, energy prices, and global economic conditions. Companies must constantly monitor and analyze these factors to set competitive prices while maintaining profitability. Moreover, the marketing of steel billets requires a thorough understanding of the target market's needs and preferences. Different industries may require specific qualities and specifications in their billets, such as size, composition, or surface finish. Companies must invest in research and development to meet these requirements and effectively communicate the advantages of their products to potential customers. Another challenge lies in establishing and maintaining strong relationships with customers. Steel billets are typically sold through long-term contracts and relationships built on trust and reliability. Building and nurturing these relationships require consistent quality, on-time delivery, and excellent customer service. Lastly, environmental sustainability is an emerging challenge in the marketing of steel billets. With increasing environmental regulations and growing consumer awareness, companies need to position themselves as environmentally responsible and promote sustainable practices throughout their value chain. In conclusion, the marketing of steel billets faces challenges related to intense competition, demand-supply dynamics, pricing, market understanding, customer relationships, and environmental sustainability. Overcoming these challenges requires strategic planning, continuous adaptation, and a customer-centric approach.

- Q:How is a steel billet made?

- Continuous casting is a common method used to produce steel billets. This process includes several steps that involve the gathering and processing of raw materials, the transformation of these materials into molten pig iron, and the refining of the molten pig iron in either a basic oxygen furnace or an electric arc furnace. In these refining furnaces, impurities are eliminated and alloying elements may be added to achieve specific properties. Once the molten steel is chemically balanced and refined, it is ready for casting. To do this, the steel is poured into a water-cooled copper mold known as a continuous caster. As it flows into the mold, the steel solidifies and takes the shape of a long rectangular or square billet. During the casting process, water is circulated through the mold to cool the steel quickly and aid in solidification. This controlled cooling ensures that the billet has a consistent structure and the desired mechanical properties. After solidification, the billet is cut into predetermined lengths using a torch or a shear. These billets can vary in size and weight depending on their intended use. Once cut, the billets can undergo further processing through rolling, forging, or other shaping methods to create various steel products such as bars, rods, tubes, or structural shapes. In summary, the production of a steel billet involves the transformation of raw materials into molten steel, the refining of the molten steel, and the casting of it into a solid shape using continuous casting. These billets then serve as the starting point for the production of a wide range of steel products used in various industries.

- Q:How do steel billets contribute to the manufacturing of medical equipment?

- Steel billets are a crucial component in the manufacturing of medical equipment as they are used to create various parts and components, such as surgical instruments, implants, and medical devices. The high-strength and durability of steel make it ideal for ensuring the reliability and longevity of these critical medical tools. Additionally, steel billets can be easily molded and shaped into the desired form, allowing manufacturers to create intricate and precise designs necessary for medical equipment.

- Q:How do steel billets contribute to the sustainability of construction projects?

- Steel billets contribute to the sustainability of construction projects in several ways. First, steel is an incredibly durable and long-lasting material. Steel billets are the raw form of steel that can be used to manufacture various construction components such as beams, columns, and reinforcement bars. These components provide structural integrity and strength to buildings, ensuring their longevity. By using steel billets, construction projects can be built to withstand extreme weather conditions and natural disasters, reducing the need for frequent repairs or replacements. This durability directly contributes to the sustainability of construction projects by reducing waste and conserving resources over time. Second, steel is a highly recyclable material. Steel billets can be recycled and reused indefinitely without losing their quality or performance. Recycling steel reduces the energy consumption, greenhouse gas emissions, and waste associated with the production of new steel. By incorporating recycled steel billets into construction projects, the demand for virgin steel can be reduced, thereby conserving natural resources and minimizing environmental impact. Additionally, the use of steel billets in construction allows for efficient and versatile designs. Steel is known for its high strength-to-weight ratio, allowing for lighter and slimmer structural elements that require fewer materials. This not only reduces the overall weight of the building, but also decreases the amount of concrete and other construction materials required. As a result, less energy is consumed in the production and transportation of these materials, leading to a more sustainable construction process. Furthermore, steel is resistant to pests, such as termites and fungi, which can cause significant damage to buildings. By using steel billets, construction projects can avoid the use of chemical treatments typically required to protect wooden structures, reducing the environmental impact of pest control measures. In conclusion, steel billets contribute to the sustainability of construction projects through their durability, recyclability, efficient design possibilities, and resistance to pests. By incorporating steel into construction, buildings can be built to last, reduce waste, conserve resources, and minimize environmental impact.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mild steel billet for sale low price made in china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15542 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords