Middle Density Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Cement Boards) Description

Waterproofing;Sound Insulation;High density;moisture proof;anti-sunk;Strength;Toughess;Anti wet; Nice thin board usage,bendable.

2,Main Features of the (Cement Boards)

Properties:

·100% Non-asbestos

·Density: 1250 to 1500 kg/m3 (+ - 5%)

·Coefficient of thermal expansion: 0.11 kcal/m.hroC

·Bending Strength: over 180 kgf/cm2

·Linear expansion rate: 0.1%

·Water absorption rate: 35%

·Water penetration rate: 0%

·Water content: 8%

·Incombustibility according to CNS 6532 and BS 476

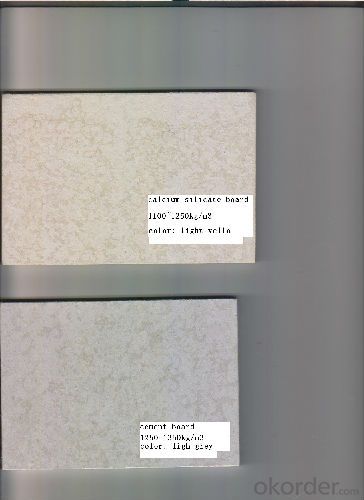

3,(Cement Boards) Images

4,(Cement Boards) Specification

| Standard Data of the Middle Density Firber Cement Board | ||||||||

| Standard Size | 1220X2440mm/1200X2400mm | Max Width | 1250mm | Max Length | 4880mm | |||

| Thickness | 4-30mm | Density | 1.3-1.7g/cm3 | |||||

| Wet Expansion Rate | ≤0.23% | Water Penetration | ≤25% | |||||

| Forst Resistance | No Layer & no cracks after 25 cycles under freezing and thawing | |||||||

| Incombustibility | Incombustible Class A1 | Radioactivity | Decorative materials Class A | |||||

| Flexural Strength | Air dried Condition ≥18 | Water Penetration | Back side without water drop after 24 hours | |||||

| Saturated Condition≥14 | ||||||||

5,FAQ of (Cement Boards)

Application

(1)Cavity Wall for Interior Partition

1.Wet area( restroom,kitchen and basement etc.)

2.High sound insulation requirements area ( pc room,meeting room and hotel etc.)

(2) Light Concrete Grouting Wall

(3) Other Applications

1. Ceiling board

2. Perforated board

3. Aluminum lining boards and insulation barriers for high-speed train

4. Column Coverage

Production Scale and Equipment

We introduced international advanced equipment and technologies. From raw materials preparation to board forming stacking and compressing, autoclaving and destacking are all controlled by strict and efficient production craft. The whole process is full automatic, high efficient and quality stable.

- Q:I have a small 4X2 area in which I need to re-tile. The area now is outdoors and is set inside of a concrete slab. Who ever installed the tiles before installed them like paver's where they backfilled the small area with sand (about 3). My question is can I use durock or another cement board to get a solid surface for tiling or do I need to refill the area with concrete? I don't know too much about concrete work which is why I am looking to use the cement boards.Thanks

- it won't last long

- Q:I think I have termites outside on my shield. I sprayed that terminix on the shield but now there are some holes that I want to cover up and since I had extra durock cement board I put it up to help keep any water or anything from going in. Is this a good idea and will the cement board be ok in the weather of the San Jose ca area.

- It will be fine. A bit overkill maybe, but it will work. Might as well use it if you already have it.

- Q:Gypsum board how to make the effect of cement

- Paste gypsum board is based on building gypsum as the main raw material, mixed with appropriate amount of additives and fiber to do the core, with a special plate for the face, the processing made of sheet metal. The gypsum board has the characteristics of light weight, sound insulation, heat insulation, strong processing performance and simple construction method.

- Q:i am going to be installing tile in my bathroom as a tub surround.i am wondering what backer board is needed. if i am using a membrane such as kerdi, is drywall a good enough backer or do i need cement board. if i need cement board, do i need the membrane? what products do you suggest for best installation. i will also be doing a walk in shower. are there any differences to be aware of compared to the tub surround shower style.

- Tile doesn't flex. Drywall does. You need a hard surface to lay tile, or the grout joints will crack, water will get in, and your tile will promptly fall off. Real tile backer board (the kind that's made out of fiber re-enforced cement) is the only decent solution for installing tile over a wood frame. Hardibacker or any other modern garbage designed to make something seemingly easier, just turns into a nasty headache a year later. Also be sure to use real thin-set mortar, and real grout. That adhesive grout is just acrylic caulking with some sand added, tiles will fall off if they get wet.

- Q:ok so im trying to attach the cooling fan to my cpu on my motherboard and i cant find any glue but i did find some patch cement in a road hazard kit, i was wondering if this would work or would my computer fry?

- You need thermal paste. You can get a very small tube, enough for 1-3 applications (?) at COMPUSA (or other such place) for under $5. I work on m-boards/processors all the time and know that some kind of adhesive would probably ruin your computer. I've had many heat sinks/fans that would not separate from the processor, and sometimes lift it out of the socket without loosening the arm that tightens it. The kind of damage cant be (easily/cheaply) repaired. Get thermal paste, apply very thin amount to proc, covering the entire (proc) heat sink. Same to heat sink/fan.

- Q:How about wood wire cement board? Is it environmentally friendly building materials?

- The cement board is very good. It is environmentally friendly green building materials, from the cement as a cross-linking agent, wood as a fiber reinforced material, adding part of the additives made of the plate, mainly by the crushed wood and Portland cement gluing processing, color cleaning, double Smooth and smooth surface. The product combines the strength of wood, ease of processing and cement durable characteristics. Wood fiber cement board in the 40's began to be widely used in Europe, has now become a wide range of international application of building materials. It is versatile, excellent performance, with corrosion resistance, heat resistance, resistance to corrosion, easy processing, and cement, lime, gypsum with good, green and other advantages. Now, the Netherlands, Finland, Germany, Austria, Russia and other countries have formed a number of such special plate manufacturing company, as well as professional equipment manufacturers, compared to China's less such production lines, wood The development of the domestic space is relatively large, to be the depth of development and utilization.

- Q:I have an existing hardwood floor that I want to tile over (it's not in good condition). Can I put cement board then tile directly onto the hardwoods or do I need plywood on the hardwoods then cement board then tile? I don't want the floors to be 2 thick in addition to the hardwoods.

- Hillbill gave you good advice. I went to the site he recommended. It's straight up. I would add this; what you're looking for when you're done with the cementatious board is level. And, screws are better than nails on a wood floor.

- Q:I have asbestos shingles and i need to vent a portable a/c so i'm going to replace a few shingles with fiber cement board so i can cut them. i heard these things are a nightmare to cut.

- A jig saw with a metal cutting blade will work. First, trace the hole you wish to cut on the surface, then drill one hole big enough for the jig saw blade to fit through. Then simply cut out your pattern. CAUTION! Don't breath in the dust since asbestos is a carcinogen. Get a filter mask at any hardware store.

- Q:I know it sounds odd but if you set a cement block between to supports and hit it with your fist its really not hard at all to break it. Why is it that a 1 thick cement block breaks easier than a 1 thick piece of pine. Also it seems like maybe its just me but if you hit a 1 thick oak board your fist doesnt have to be in contact as long to break it. With the cement block it doesn't take much to make it break.

- density. wood is long strands of thick, dense fiber essentially strung together, cement is a mix of individual rocks with a water/concrete bonding, but there is air mixed in during the mixing process. there are more areas in between the rocks to be weaker, less dense. this may be a bad example.. but liken it to a bathtub with water that is iced over completely, and a bathtub with only ice water.. in between the ice, you can put your hand through, because it is essentially water and less dense than the ice... but with the completely covered ice water, you cannot easily put your hand through.. . i guess also i was thinking of a game of red rover if you have ever played it, it is easier to run through when the other team is holding hands, than when they link elbows.. essentially making the bond stronger with bigger parts of the arm.

- Q:Can cutting the steel cutting machine cut the cement board?

- Can not cut the reinforced toothless saws are grinding wheel pieces, while cutting the concrete slabs to use the toothless alloy steel saw blade.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Middle Density Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords