Microporous Insulation Board Classification Temperature:1000-1100C

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Microporous Insulation Board:

CMDS Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

2.Main features of Microporous Insulation Board:

◆ Extremely low thermal conductivity ◆High compressive strength

◆ High thermal stability ◆Environment protection

◆ Easy to handle ◆No harmful inhalable fibers

◆ Resist most chemical attacks ◆Free of organic binders

◆ Non combustible

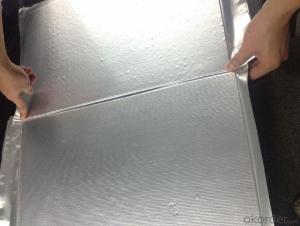

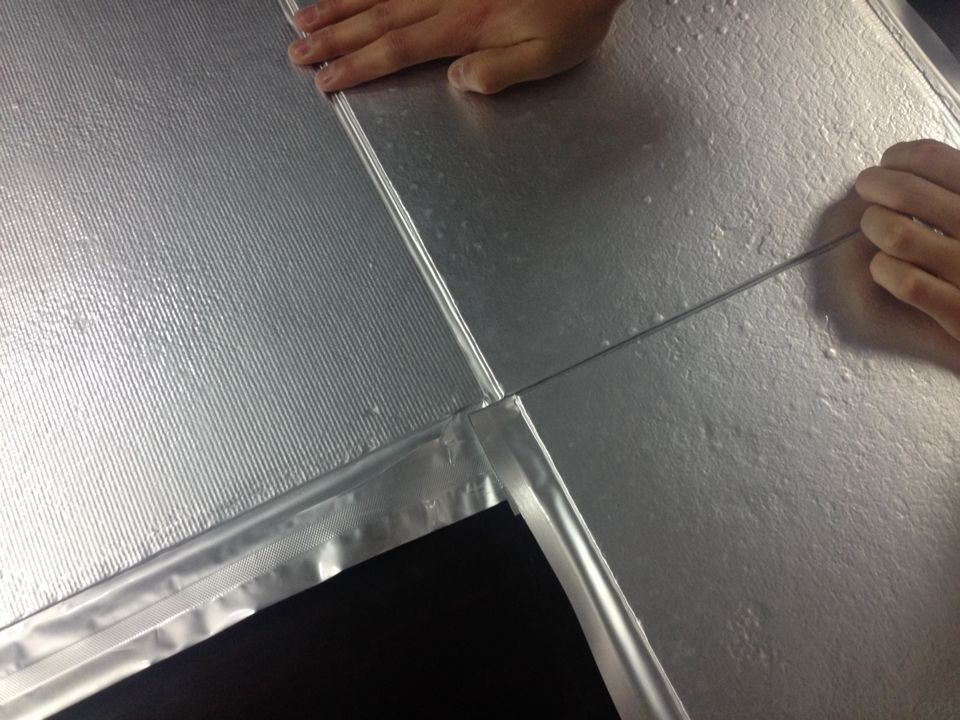

3. Microporous Insulation Board Images:

4. Microporous Insulation Board Technical Parameters

CMDS Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The board can be fixed in place with the same adhensives that are used for refractory lining.

Application: Ladle, Torpedo Ladle, EAF, Degassers, Cement Rotary Kiln, Ceramic Firing Klin, Aluminum Melting and Holding Furnace and so on. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of Microporous Insulation Board is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Villa roof leakage what general reasons, what materials to remedy

- ??Note: Before the waterproofing and draining construction, the roof must be dry, because the roof of the water does not evaporate, the new waterproof layer will rise, the waterproof effect immediately invalid. Therefore, rainy days should not be construction, to wait until the sun will dry the water before construction.

- Q:Roof membrane waterproof construction process, what should be noted that?

- Four do not: 1 surface can not afford sand 2 surface can not afford skin 3 surface is not crisp 4 does not crack

- Q:How can the toilet waterproof works fail?

- Use 755 new waterproof material can be painted three times. There is also a new type of waterproof material is water-like brush is also three times, you can go to the building materials market to see, you know.

- Q:Do you use the waterproof material on the building to be harmful to the human body?

- Your pores, the respiratory tract, the lungs, will be hurt, when young do not feel out, the consequences more powerful than smoking.

- Q:There is no formaldehyde in the finished putty

- Often people are talking aldehyde color change, because the formaldehyde is very polluted environment contains a lot of carcinogenic substances, so into the wall inside unknowingly become an environmental killer.

- Q:I would like to ask how to do in the warm water above,

- Do not know why you are in the floor to do the top of the waterproof? The We are here in the northeast of the winter is very cold, are warm, no one to warm the ground to do the above water, I think you over and over again, ah, no need, every family is warm, you have to do waterproof in the above is afraid of soaking your floor or tiles Bubble? The If the pipe really leaked, did not use the waterproof, the first warm tube must be selected, followed by your shop is good or bad, workers, water, are very important, you focus on this line on the line

- Q:What is the price of a waterproof window cover?

- 3, decorative panels Decorative panels are divided into paint-free panels and paint panels. Currently on the market, there are many window-free products, paint-free board is 5 mm density, the board pressure a layer of thin layer of color paper, due to the type of color paper, so there can be a lot of paint-free Color. Paint decorative panel is the surface of a layer of veneer plywood, there are many types, different wood has different colors. The benefits of window sets

- Q:How does the waterproofing membrane work?

- 4, rolling the membrane: the first turn up the end of 1m long, with a long torch melting the bottom of the hot melt adhesive, the rapid paste fixed on the grassroots, and then re-harvest the rest of the volume. The gunmen stood on the paved webs, aligned with the corners of the rolls and the surface of the base layer with the flame of the long gun, and slowly rolled the edges by melting the hot melt. The web is pasted on the base;

- Q:Waterproof mortar expensive or dry mortar expensive

- Cationic neoprene latex is a polymer modified polymer anti-corrosion system. By the introduction of imported epoxy resin modified latex by adding the domestic neoprene emulsion and polyacrylate, synthetic rubber, various emulsifiers, modified latex and other components of the polymer latex.

- Q:How to do waterproof bathroom, construction process is what

- 3, shop protective layer. In order to prevent the subsequent construction damage to the waterproof layer, the need to cover the surface of the waterproof coating protective layer. Protective layer to completely cover the waterproof layer, no missing, with the grass-roots combination of solid, no cracks, no bubbles, no shedding phenomenon.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Microporous Insulation Board Classification Temperature:1000-1100C

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords