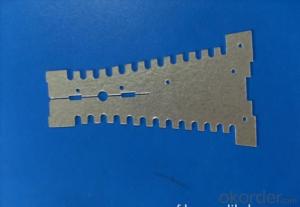

Mica Tubes Used in Air Blower in Industry Field

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction:

Mica tube is made of mica paper with highperformance organic silicon resin. After heating and pressing, the mica plate can be made into rigid or flexible insulating plates. The mica content is about 90% and the organic silicon resin content is 10%.

2. Main features of Mica Parts:

Rigid mica tubes are featured with high strength, good performance, less smoke, less odor etc.

3. Applications:

This series mica plates are used mainly in household appliances (toaster ovens, microwave ovens, warm air blowers, hair dryers, electric iron etc.), metallurgy (such as linefrequency furnaces, medium frequency furnaces, electric arc furnace, etc.), medical equipment and other industries, used as the heating support, lining plate and partition plate of the electric appliances described above.

4. Technical Parameters:

Tolerance for mica tube | ||

Internal diameter(mm) | Tolerance of ID(mm) | Tolerance of ID(mm) |

<10< span=""> | ±0.3 | ±0.4 |

10 ~ 20 | ±0.4 | ±0.5 |

21 ~ 50 | ±0.5 | ±0.7 |

51 ~ 100 | ±0.6 | ±1.0 |

101 ~ 200 | ±0.8 | ±1.2 |

201 ~ 300 | ±1.0 | ±1.5 |

Length: 10mm to 1000mm | ||

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q:What are the gas insulation materials?

- Gas insulation material refers to air, nitrogen, sulfur hexafluoride and other gases

- Q:What is the insulating material in the middle of the connecting wire?

- With a transparent tape isolation, with hot melt adhesive fixed thread, with heat shrink tube insulation, a lot of ways ah.

- Q:What insulating materials are used for high frequency transformers?

- Where the water is mainly a resin and solvent or resin, oil and solvent composition, is based on polymer polymer, under certain conditions can be cured into an insulating film or insulation of the important insulation material, applied to high-frequency transformers After the surface, the solvent evaporates, the resin or the resin and the oil form a smooth film, showing the original pattern of the object. Easy to dry and durable, and can acid and oil.

- Q:What insulating material is used for high voltage cables

- YJLV23 Aluminum core XLPE insulated steel tape armored PVC sheathed power cable YJV32 copper core XLPE insulated fine steel wire armored PVC sheathed power cable indoor, tunnel, cable trench, shaft or buried

- Q:What are the electrical insulation materials

- Insulation material is electrical insulation material. According to the national standard GB2900.5 provides the definition of insulating material is: "used to make the device in the electrical insulation of the material." That is, to prevent the current through the material. Its resistivity is very high, usually in the range of 10 ^ 9 ~ 10 ^ 22Ω · m. As in the motor, the insulating material around the conductor isolates the turns and isolates it from the grounded stator core to ensure safe operation of the motor.

- Q:What is the thermal aging and electrical aging of insulating materials?

- Insulation materials in electrical equipment during the operation, due to the long-term effects of various factors, there will be a series of irreversible physical and chemical changes, resulting in its electrical performance and mechanical properties decline, commonly known as aging. There are many factors that affect the aging of insulating materials. The main aging forms are environmental aging, heat aging and electrical aging.

- Q:What is the DMD insulation material?

- DMD insulating paper, the product is a layer of polyester film coated with adhesive, one side for the polyester fiber non-woven composite, calendering from a composite insulation products, referred to as DMD.

- Q:What type of enameled wire and insulation material is used for the compressor

- Enclosed wire and insulation materials for fully enclosed compressors: 1) Refrigerant R12, enameled wire with high strength polyester QZ, insulated with 6400 epoxy resin Insulation H34-4, Polyurethane film for insulating material Green paper (DMD ) Insulation paper; 2) refrigerant R22 and R502, with QF, QXY polyamide imide enameled wire, insulation treatment with EIU epoxy modified impregnated varnish, insulating material with polyimide film and poly Fiber composite foil, F-class insulation DMD insulation paper.

- Q:Brass is not an insulating material?

- Brass is a particularly good conductive material and is a good material for wearing heat

- Q:What kind of insulation is the insulating

- Now most of the aluminum substrate in the insulating layer or epoxy (I do this, do not mention my company name, so that I advertise). Epoxy can be modified, and then through the surface treatment of the thermal filler, in the cross-linked when the formation of a most conducive to the heat transfer structure, so as to achieve the purpose of high thermal conductivity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mica Tubes Used in Air Blower in Industry Field

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords