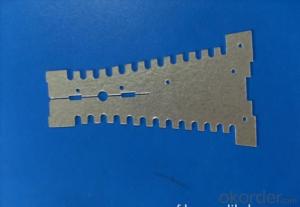

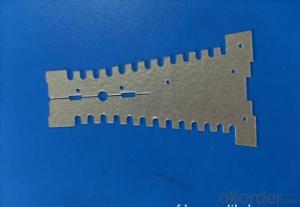

Mica Parts Used in Industry for Air Heater

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C).

2.Main features of Mica Parts:

Mica heating elementsoffer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

3. Applications:

Typical applications of mica heating elements are air heaters, enclosure systems, food service equipment, process and packaging equipment.

4. Technical Parameters:

MICA SHEET -----Technical data | ||||||||

ITEM | UNIT | RM | RP | RM-T | RP-T | FM | FP | |

Hardness |

| Rigid | Rigid | Rigid | Rigid | Flexible | Flexible | |

Mica paper |

| Muscovite | Phlogopite | Muscovite | Phlogopite | Muscovite | Phlogopite | |

Thickness | mm | 0.1-2.0 | 0.1-2.0 | 3.0-50 | 3.0-50 | 0.1-2.0 | 0.1-2.0 | |

Mica content | % | ≥90 | ≥90 | >88 | >88 | ≥90 | ≥90 | |

Bond Content | % | <10< span=""> | <10< span=""> | <12< span=""> | <12< span=""> | <10< span=""> | <10< span=""> | |

Density | g/m 3 | 1.6~2.45 | 1.6~2.45 | 2.1~2.4 | 2.1~2.4 | 1.6~2.45 | 1.6~2.45 | |

Heat | Continuous | ℃ | 500 | 700 | 500 | 700 | 500 | 700 |

Peak | ℃ | 700 | 900 | 700 | 900 | 700 | 900 | |

Heat loss at 500℃ | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | <1< span=""> | <1< span=""> | |

Heat loss at 700℃ | % | <2< span=""> | <2< span=""> | <1< span=""> | <2< span=""> | <2< span=""> | <2< span=""> | |

Flexural strength | Mpa | >160 | >140 | — | — | <1< span=""> | <1< span=""> | |

Water absorption 24h/23°C | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | — | — | |

Dielectric strength | KV/mm | >20 | >20 | >15 | >15 | >15 | >15 | |

Volume | 23℃ | ΩNaN | >1017 | >1017 | >1017 | >1017 | — | — |

500℃ | ΩNaN | >1012 | >1012 | >1012 | >1012 | — | — | |

Smoking Test | s | <4< span=""> | <4< span=""> | — | — | — | — | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q:What is the electrical performance of insulating materials

- Such as the rated voltage, current, active power, reactive power, resistance, capacitance, inductance, conductance; semiconductor is famous, DC magnification, AC magnification, rectified current, reverse breakdown voltage, forward voltage , The junction voltage, the noise figure, the characteristic frequency, the cut-off frequency, the dissipation power ... the IC is also very large, the maximum working voltage, the op amp's pendulum speed, the bandwidth, the distortion coefficient, the ADC conversion rate, , The resolution of plastic in the field of electrical applications is extremely extensive, its role is mainly two aspects, one as electrical insulation materials, two for the mechanical structure of materials. These materials are used in the field of electrical engineering, mainly in the electrical, electrical and electrical industries.

- Q:What are the gas insulation materials?

- Gas insulation material refers to air, nitrogen, sulfur hexafluoride and other gases

- Q:What insulating materials are used for high frequency transformers?

- Can be brush, can be sprayed, can be baked Here is the main raw material for ice making. Selection of industrial products. All around the paint factory production. General high-frequency transformer insulation materials used by the scope and form are divided into: impregnated paint, covering paint, silicon steel paint, anti-corona paint four.

- Q:What are the electrical insulation materials

- Insulation material is electrical insulation material. According to the national standard GB2900.5 provides the definition of insulating material is: "used to make the device in the electrical insulation of the material." That is, to prevent the current through the material. Its resistivity is very high, usually in the range of 10 ^ 9 ~ 10 ^ 22Ω · m. As in the motor, the insulating material around the conductor isolates the turns and isolates it from the grounded stator core to ensure safe operation of the motor.

- Q:What is the thermal aging and electrical aging of insulating materials?

- Insulation materials in electrical equipment during the operation, due to the long-term effects of various factors, there will be a series of irreversible physical and chemical changes, resulting in its electrical performance and mechanical properties decline, commonly known as aging. There are many factors that affect the aging of insulating materials. The main aging forms are environmental aging, heat aging and electrical aging.

- Q:There are a lot of online about this, but still do not understand. If the insulation resistance is high enough, hit the pressure should also be qualified ah. There is insulation test itself when the current flow is not large, because the rock table resistance is great. But hit the pressure, I do not know is not a direct high pressure drop in the test product above, there is no great resistance to interference?

- Because the voltage generated by the withstand voltage test is generally greater than twice the rated voltage of the electrical equipment, and the insulation resistance test voltage value and the rated voltage is similar. And the withstand voltage test for the alternating current, insulation resistance test for the DC. Will have a certain impact on its test results.

- Q:What is the DMD insulation material?

- These small mirrors are approximately 16 or 14 microns in size and are usually made up of an array of up to 50 to 2 million, with a gap between the mirrors of 1 micron and a mirror rotating with an aluminum hinge as a rotation axis 10- 12 degrees, can be used repeatedly 1 trillion, life test shows that in accordance with the usual use can be used for 100,000 hours. Its opening and closing control is through the mirror stop when the damping effect of the spring contact near the mirror, gradually reduce the way the additional voltage to achieve. DMD chip has been upgraded, the original chip on the microscope size of 16 microns, flip angle of 10 degrees, the current DMD micrometer size of 14 microns, flip 12 degrees, support 4K resolution chip has also been formed, the chip size of about 1.38 Inch.

- Q:What are the commonly used insulating materials?

- Commonly used inorganic insulation materials are: mica, asbestos, marble, porcelain, glass, sulfur and so on, which can be divided into inorganic insulating materials, organic insulating materials and mixed insulating materials.

- Q:What insulating material is best `?

- The earliest use of insulating materials is cotton, silk, mica, rubber and other natural products .20 century 30 years later, the rapid development of synthetic insulation materials, a variety of synthetic resin, plastic, etc. used in the field of electrical engineering to manufacture motor and high and low pressure Electrical appliances, so that the capacity of electrical products continue to expand, the volume gradually reduced, so as to promote the development of electrical and electronic technology.

- Q:What is the main purpose of insulating materials?

- Second, the heat resistance is better, to avoid long-term overheating and aging deterioration; In addition, there should be good thermal conductivity, resistance to lightning resistance and high mechanical strength and process processing and other characteristics. According to the above requirements, commonly used insulating material performance Indicators of insulation strength, tensile strength, specific gravity, expansion coefficient.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mica Parts Used in Industry for Air Heater

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords