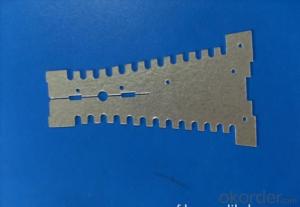

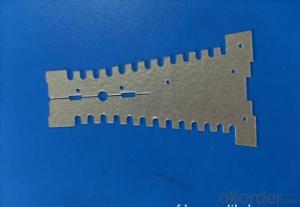

Mica Parts Used for Packageing Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introductions:

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C). Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures.

2. Applications:

Typical applications of mica heating elements are air heaters, enclosure systems, food service equipment, process and packaging equipment. Our mica heating element is made by detail order requirments.

3. Main features of Mica Parts:

Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures.

4. Technical Parameters:

MICA SHEET -----Technical data | ||||||||

ITEM | UNIT | RM | RP | RM-T | RP-T | FM | FP | |

Hardness |

| Rigid | Rigid | Rigid | Rigid | Flexible | Flexible | |

Mica paper |

| Muscovite | Phlogopite | Muscovite | Phlogopite | Muscovite | Phlogopite | |

Thickness | mm | 0.1-2.0 | 0.1-2.0 | 3.0-50 | 3.0-50 | 0.1-2.0 | 0.1-2.0 | |

Mica content | % | ≥90 | ≥90 | >88 | >88 | ≥90 | ≥90 | |

Bond Content | % | <10< span=""> | <10< span=""> | <12< span=""> | <12< span=""> | <10< span=""> | <10< span=""> | |

Density | g/m 3 | 1.6~2.45 | 1.6~2.45 | 2.1~2.4 | 2.1~2.4 | 1.6~2.45 | 1.6~2.45 | |

Heat | Continuous | ℃ | 500 | 700 | 500 | 700 | 500 | 700 |

Peak | ℃ | 700 | 900 | 700 | 900 | 700 | 900 | |

Heat loss at 500℃ | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | <1< span=""> | <1< span=""> | |

Heat loss at 700℃ | % | <2< span=""> | <2< span=""> | <1< span=""> | <2< span=""> | <2< span=""> | <2< span=""> | |

Flexural strength | Mpa | >160 | >140 | — | — | <1< span=""> | <1< span=""> | |

Water absorption 24h/23°C | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | — | — | |

Dielectric strength | KV/mm | >20 | >20 | >15 | >15 | >15 | >15 | |

Volume | 23℃ | ΩNaN | >1017 | >1017 | >1017 | >1017 | — | — |

500℃ | ΩNaN | >1012 | >1012 | >1012 | >1012 | — | — | |

Smoking Test | s | <4< span=""> | <4< span=""> | — | — | — | — | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q:Who knows what are the ability of 1300 degrees above the high temperature, insulation materials?

- Heat-resistant polymers can be used as high temperature resistant film insulation materials, high temperature resistant fibers, high temperature resistant coatings, high temperature adhesives. In accordance with the high temperature of the time, but also sub-instant high temperature materials and high temperature materials for a long time. The former in 1000 ~ 10000 ℃ can withstand a few seconds to a few minutes.

- Q:What are the gas insulation materials?

- In addition to air, nitrogen, carbon dioxide and sulfur hexafluoride gas, there are other gases used for insulation. CCl2F2 (freon-12) was used as an insulating in certain high-energy physical devices. CCl2F2 breakdown strength and SF6 similar, but because of its high liquefaction temperature, and the spark will make CCl2F2 precipitation of carbon particles, therefore, has been replaced by SF6. In hydrogen-cooled generators, hydrogen is also used as insulation in addition to cooling media.

- Q:What is the insulating material in the middle of the connecting wire?

- The original wire is insulated paint, you often use, you can also use quick-drying insulating paint.

- Q:There are a lot of online about this, but still do not understand. If the insulation resistance is high enough, hit the pressure should also be qualified ah. There is insulation test itself when the current flow is not large, because the rock table resistance is great. But hit the pressure, I do not know is not a direct high pressure drop in the test product above, there is no great resistance to interference?

- Insulation test Because the test voltage is low, it is not easy to damage the equipment under test. The voltage test is easy to damage the equipment under pressure when the test voltage is high. In some cases, although the withstand voltage test is passed, Causing damage, the test staff will have to use low-voltage insulation test, test the pressure test after the test equipment insulation. Under normal circumstances, insulation resistance qualified, withstand voltage test will be adopted.

- Q:What insulating materials are used for transformers

- With the largest number of cardboard, as well as laminated wood, insulating paper, transformer oil, large oil-immersed transformers are mostly oil - paper insulation.

- Q:What is the DMD insulation material?

- DMD (Dacron / Mylar / Dacron) full name polyester film polyester fiber non-woven soft composite foil, is a two-layer polyester non-woven fabric in the middle of a layer of insulated polyester film composite made of three insulation materials.

- Q:What are the commonly used insulating materials?

- Commonly used inorganic insulation materials are: mica, asbestos, marble, porcelain, glass, sulfur and so on, which can be divided into inorganic insulating materials, organic insulating materials and mixed insulating materials.

- Q:What type of enameled wire and insulation material is used for the compressor

- Motor insulation class The insulation class is divided according to the permissible limit temperature of the insulation material used for the motor. There are Y, A, E, B, F, H, C and several other levels, the allowable limit temperature at all levels as shown in the table below. The so-called permissible limit temperature refers to the permissible maximum operating temperature of the motor insulation material, which reflects the heat resistance of the insulating material. Insulation material is divided into Y grade, A grade, grade E, grade B, grade F, grade H, grade C, permissible temperature (℃) 90,105,120,130,155,180, 180 ℃ or higher.

- Q:Brass is not an insulating material?

- Brass is not insulating material. On the contrary is the brass is conductive material. Brass texture hard, can not bend. No copper flexibility is good, so brass can only do a fixed copper conductive use.

- Q:What is the main purpose of insulating materials?

- Second, the heat resistance is better, to avoid long-term overheating and aging deterioration; In addition, there should be good thermal conductivity, resistance to lightning resistance and high mechanical strength and process processing and other characteristics. According to the above requirements, commonly used insulating material performance Indicators of insulation strength, tensile strength, specific gravity, expansion coefficient.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mica Parts Used for Packageing Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches