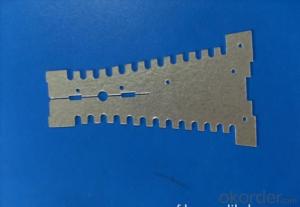

Mica Parts Used for Industry of Medical Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction:

Mica plate is made of mica paper with high-performance organic silicon resin. After heating and pressing, the mica plate can be made into rigid or flexible insulating plates. The mica content is about 90% and the organic silicon resin content is 10%

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C). Mica heating elements

offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher

operating temperatures. Our mica heating element is made by detail order requirments.

2.Main features of Mica Parts:

Rigid mica plates are featured with high strength, good performance, less smoke, less odor etc. This series mica plates are used mainly in household appliances (toaster ovens, microwave ovens, warm air blowers, hair dryers, electric iron etc.), metallurgy (such as line-frequency furnaces, medium frequency furnaces, electric arc furnace, etc.), medical equipment and other industries, used as the heating support, lining plate and partition plate of the electric appliances described above.

3. Technical Parameters:

MICA SHEET -----Technical data | ||||||||

ITEM | UNIT | RM | RP | RM-T | RP-T | FM | FP | |

Hardness |

| Rigid | Rigid | Rigid | Rigid | Flexible | Flexible | |

Mica paper |

| Muscovite | Phlogopite | Muscovite | Phlogopite | Muscovite | Phlogopite | |

Thickness | mm | 0.1-2.0 | 0.1-2.0 | 3.0-50 | 3.0-50 | 0.1-2.0 | 0.1-2.0 | |

Mica content | % | ≥90 | ≥90 | >88 | >88 | ≥90 | ≥90 | |

Bond Content | % | <10< span=""> | <10< span=""> | <12< span=""> | <12< span=""> | <10< span=""> | <10< span=""> | |

Density | g/m 3 | 1.6~2.45 | 1.6~2.45 | 2.1~2.4 | 2.1~2.4 | 1.6~2.45 | 1.6~2.45 | |

Heat | Continuous | ℃ | 500 | 700 | 500 | 700 | 500 | 700 |

Peak | ℃ | 700 | 900 | 700 | 900 | 700 | 900 | |

Heat loss at 500℃ | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | <1< span=""> | <1< span=""> | |

Heat loss at 700℃ | % | <2< span=""> | <2< span=""> | <1< span=""> | <2< span=""> | <2< span=""> | <2< span=""> | |

Flexural strength | Mpa | >160 | >140 | — | — | <1< span=""> | <1< span=""> | |

Water absorption 24h/23°C | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | — | — | |

Dielectric strength | KV/mm | >20 | >20 | >15 | >15 | >15 | >15 | |

Volume | 23℃ | ΩNaN | >1017 | >1017 | >1017 | >1017 | — | — |

500℃ | ΩNaN | >1012 | >1012 | >1012 | >1012 | — | — | |

Smoking Test | s | <4< span=""> | <4< span=""> | — | — | — | — | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q:What is the electrical performance of insulating materials

- Insulation material electrical performance mainly refers to: good dielectric properties, high insulation resistance and compressive strength. Do not occur leakage, creeping or breakdown and other accidents. Good heat resistance performance in the long-term heating state no significant change in performance. Good thermal conductivity, moisture resistance and mildew resistance.

- Q:What are the gas insulation materials?

- The relative breakdown strength of air (at air 1) at the standard pressure (101335Pa) is as follows: nitrogen, 1; hydrogen, 0.5; carbon dioxide, 0.9; sulfur hexafluoride, 2.5; freon-12,2.7 The

- Q:Wear-resistant, high temperature, insulation materials which

- Epoxy, temperature from 100-400 degrees, processing more convenient. Ceramic is the best and cheap.

- Q:What insulating material is used for high voltage cables

- Features: The rated voltage of the cable is 6kv. The long-term operating temperature of the cable is + 65 ° C. The minimum bend radius of the cable is 6 times the cable diameter.

- Q:What are the electrical insulation materials

- Many types of insulating materials, can be divided into gas, liquid, solid three categories. Commonly used gas insulation materials are air, nitrogen, sulfur hexafluoride and so on. Liquid insulation materials are mainly mineral insulating oil, synthetic insulating oil (silicone oil, dodecyl benzene, polyisobutylene, isopropyl biphenyl, diaryl ethane, etc.) two categories. Solid insulation materials can be divided into organic, inorganic two categories. Organic solid insulation materials include insulating varnishes, insulating glue, insulating paper, insulating fiber products, plastic, rubber, lacquered lacquers and insulating impregnated fiber products, electrical thin films, composite products and adhesive tape, electrical laminates and so on. Inorganic solid insulation materials are mainly mica, glass, ceramics and their products. In contrast, solid insulation material variety, but also the most important. Different electrical equipment requirements for the performance of insulating materials are focused. High-voltage electrical equipment such as high-voltage motors, high-voltage cables and other insulation materials require high breakdown strength and low dielectric loss.

- Q:There are a lot of online about this, but still do not understand. If the insulation resistance is high enough, hit the pressure should also be qualified ah. There is insulation test itself when the current flow is not large, because the rock table resistance is great. But hit the pressure, I do not know is not a direct high pressure drop in the test product above, there is no great resistance to interference?

- Insulation resistance is measured with an insulation resistance tester (10000V or less) or an insulation shaking table (2500V or less). Since the test voltage is low, many insulation defects are not easily found; the withstand voltage test test voltage is high and the high pressure equipment is easily found Insulation defects;

- Q:What are the commonly used insulating materials?

- Mainly used for motor, electrical winding insulation, switch the bottom plate and insulators, etc. Organic insulation materials are: shellac, resin, rubber, cotton yarn, paper, linen, rayon,

- Q:What insulating material is best `?

- Liquid insulation material, also known as insulating oil. Fill the internal or inter-electrode gap between the solid material to improve its dielectric properties and improve the cooling capacity of the equipment. Liquid insulation material high breakdown strength, dielectric loss tangent (tgσ) small, insulation resistance High specific dielectric constant, in addition, also has excellent physical and chemical properties, such as high gasification temperature, high flash point, low freezing point, thermal conductivity, thermal stability, in the electric field under the suction Small and so on.

- Q:What kind of insulation is the insulating

- Insulation is the core technology of aluminum substrate. Currently on the market most of the aluminum substrate insulation layer using epoxy resin, the advantages of this type of insulation is: good adhesion; drawback is: thermal resistance, dielectric strength is limited, it is difficult to meet the safety requirements. Such aluminum substrates are only suitable for low power density applications. High-end aluminum substrate insulation layer is generally composed of high thermal conductivity and high insulation ceramic powder filled with special polymer composition.

- Q:The electrical equipment in the classroom which uses insulating material

- Insulation material description: Insulation material is electrical insulation material. According to the national standard GB2900.5 provides the definition of insulating material is: "used to make the device in the electrical insulation of the material." That is, to prevent the current through the material. Its resistivity is very high, usually in the range of 10 ^ 9 ~ 10 ^ 22Ω · m. As in the motor, the insulating material around the conductor isolates the turns and isolates it from the grounded stator core to ensure safe operation of the motor.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mica Parts Used for Industry of Medical Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords