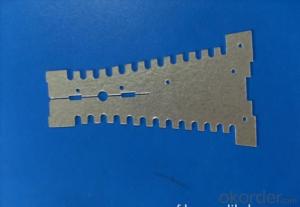

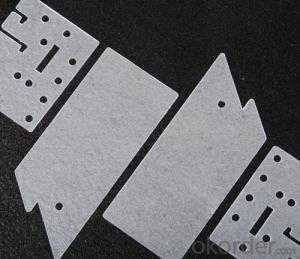

Mica Parts Usded in Electric Arc Furnace Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction:

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C). Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

Mica plate is made of mica paper with highperformance organic silicon resin. After heating and pressing, the mica plate can be made into rigid or flexible insulating plates. The mica content is about 90% and the organic silicon resin content is 10%.

2. Applications:

Typical applications of mica heating elements are air heaters, enclosure systems, food service equipment, process and packaging equipment.

3. Main features of Mica Parts:

Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures.

4. Technical Parameters:

MICA SHEET -----Technical data | ||||||||

ITEM | UNIT | RM | RP | RM-T | RP-T | FM | FP | |

Hardness |

| Rigid | Rigid | Rigid | Rigid | Flexible | Flexible | |

Mica paper |

| Muscovite | Phlogopite | Muscovite | Phlogopite | Muscovite | Phlogopite | |

Thickness | mm | 0.1-2.0 | 0.1-2.0 | 3.0-50 | 3.0-50 | 0.1-2.0 | 0.1-2.0 | |

Mica content | % | ≥90 | ≥90 | >88 | >88 | ≥90 | ≥90 | |

Bond Content | % | <10< span=""> | <10< span=""> | <12< span=""> | <12< span=""> | <10< span=""> | <10< span=""> | |

Density | g/m 3 | 1.6~2.45 | 1.6~2.45 | 2.1~2.4 | 2.1~2.4 | 1.6~2.45 | 1.6~2.45 | |

Heat | Continuous | ℃ | 500 | 700 | 500 | 700 | 500 | 700 |

Peak | ℃ | 700 | 900 | 700 | 900 | 700 | 900 | |

Heat loss at 500℃ | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | <1< span=""> | <1< span=""> | |

Heat loss at 700℃ | % | <2< span=""> | <2< span=""> | <1< span=""> | <2< span=""> | <2< span=""> | <2< span=""> | |

Flexural strength | Mpa | >160 | >140 | — | — | <1< span=""> | <1< span=""> | |

Water absorption 24h/23°C | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | — | — | |

Dielectric strength | KV/mm | >20 | >20 | >15 | >15 | >15 | >15 | |

Volume | 23℃ | ΩNaN | >1017 | >1017 | >1017 | >1017 | — | — |

500℃ | ΩNaN | >1012 | >1012 | >1012 | >1012 | — | — | |

Smoking Test | s | <4< span=""> | <4< span=""> | — | — | — | — | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q:What are the gas insulation materials?

- Gas insulation material refers to air, nitrogen, sulfur hexafluoride and other gases

- Q:What is the insulating material in the middle of the connecting wire?

- The original wire is insulated paint, you often use, you can also use quick-drying insulating paint.

- Q:What insulating material is used for high voltage cables

- Etc., can withstand mechanical force and a certain tension. YJLV32 aluminum core XLPE insulated fine steel wire armored PVC sheathed power cable YJV33 copper core XLPE insulated fine steel wire armored PVC sheathed power cable YJLV33 aluminum core XLPE insulated steel tape armored PVC sheathed power cable

- Q:What are the electrical insulation materials

- Many types of insulating materials, can be divided into gas, liquid, solid three categories. Commonly used gas insulation materials are air, nitrogen, sulfur hexafluoride and so on. Liquid insulation materials are mainly mineral insulating oil, synthetic insulating oil (silicone oil, dodecyl benzene, polyisobutylene, isopropyl biphenyl, diaryl ethane, etc.) two categories. Solid insulation materials can be divided into organic, inorganic two categories. Organic solid insulation materials include insulating varnishes, insulating glue, insulating paper, insulating fiber products, plastic, rubber, lacquered lacquers and insulating impregnated fiber products, electrical thin films, composite products and adhesive tape, electrical laminates and so on. Inorganic solid insulation materials are mainly mica, glass, ceramics and their products. In contrast, solid insulation material variety, but also the most important. Different electrical equipment requirements for the performance of insulating materials are focused. High-voltage electrical equipment such as high-voltage motors, high-voltage cables and other insulation materials require high breakdown strength and low dielectric loss.

- Q:What is the 8 ° C rule for insulating materials?

- Such as A-class insulation material limit working temperature of 105 ℃, when the ultimate operating temperature of 8 ℃, its life will be reduced by about half, which is 8 ℃ thermal deterioration rules.

- Q:There are a lot of online about this, but still do not understand. If the insulation resistance is high enough, hit the pressure should also be qualified ah. There is insulation test itself when the current flow is not large, because the rock table resistance is great. But hit the pressure, I do not know is not a direct high pressure drop in the test product above, there is no great resistance to interference?

- Insulation resistance is measured with an insulation resistance tester (10000V or less) or an insulation shaking table (2500V or less). Since the test voltage is low, many insulation defects are not easily found; the withstand voltage test test voltage is high and the high pressure equipment is easily found Insulation defects;

- Q:What is the DMD insulation material?

- These small mirrors are approximately 16 or 14 microns in size and are usually made up of an array of up to 50 to 2 million, with a gap between the mirrors of 1 micron and a mirror rotating with an aluminum hinge as a rotation axis 10- 12 degrees, can be used repeatedly 1 trillion, life test shows that in accordance with the usual use can be used for 100,000 hours. Its opening and closing control is through the mirror stop when the damping effect of the spring contact near the mirror, gradually reduce the way the additional voltage to achieve. DMD chip has been upgraded, the original chip on the microscope size of 16 microns, flip angle of 10 degrees, the current DMD micrometer size of 14 microns, flip 12 degrees, support 4K resolution chip has also been formed, the chip size of about 1.38 Inch.

- Q:What insulating material is best `?

- According to their polarity is divided into weak polarity, non-polarity, polarity and strong polarity 4. According to the material source is divided into mineral insulating oil, synthetic insulating oil and vegetable oil 3. Mineral insulating oil referred to as mineral oil, The relative dielectric constant is about 2.2, and the breakdown voltage in the standard electrode is 35 to 50 kV (kV). The flash point is 125 to 135 ° C for the manufacture of transformers and cables , Capacitors, etc. Synthetic insulating oil is a synthetic liquid insulating material.As the mineral oil is a mixture of various hydrocarbons, it is difficult to remove the components of the insulation performance, and the preparation process is complex, easy to burn, low heat resistance , The dielectric constant is not high, so the research and development of the excellent performance of the synthetic insulating oil. Now have used aromatic synthetic oil, silicone oil, ester oil, ether and sulfone synthetic oil, polybutylene, etc. Vegetable oil use Castor oil, soybean oil, rapeseed oil, etc. Castor oil is an excellent dip capacitor for pulse capacitors

- Q:Brass is not an insulating material?

- Brass is a particularly good conductive material and is a good material for wearing heat

- Q:What insulating materials do you need for power tools?

- Reinforced insulation: the voltage between the live parts and the accessible housing is 3750V, such as the voltage between the brush and the cover surface; double insulation: basic insulation + additional insulation. Main insulating material: green paper or DMD Insulation paper for basic insulation; shaft insulation and plastic housing for additional insulation; rotor insulation end plate, stator insulation end plate, used to control the creepage distance and electrical clearance; brush grip bakelite powder, used to strengthen the insulation; other parts (Power plugs, commutators, switches, etc.) These are pressure requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mica Parts Usded in Electric Arc Furnace Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords