Metrocopo Tile Forming Machine For Aluminum Coils with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Metrocopo Tile Roll forming machine

Technical data of metrocopo tile roll forming machine

Suitable Material | Q235 color steel sheet;0.4-0.6mm | |

Working speed | About 3.0m/min | |

Step distanc | adjustable according to requirement (>=250mm) | |

Power Requirement | Main motor power: 5.5 Kw(Depend on final design) | |

Hydraulic station power: 5.5Kw(Depend on final design) | ||

Material of forming rollers | No.45 steel, plated with chrome on surface. | |

Material of cutter,pressing die | Cr12 mould steel with quench treatment, HRC58-60 | |

Material of shaft | High quality 45# steel, Dia. is 72mm. | |

Shaft diameter | 72mm | |

Controlling system | Mitsubishi PLC & converter | |

Total weight of machine | About 10500KGS | |

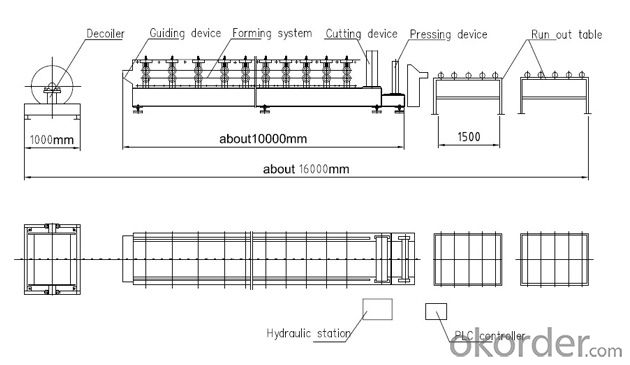

Machine''''''''s size | About 18m×1.8m× 1.5m (Depend on final design) | |

Layout drawing of machine

Our Metrocopo Tile Roll Forming Machine’s advantages

| 1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome . 2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation. 3. Cutter blade: Cr12 mould steel with quenched treatment, long life time. 4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance. 5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction. 6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines. |

- Q:What are the metal cutting machine tools?

- The machining of metal is carried out by means of machine tools or hand tools. The main methods are vehicle, milling, planing, grinding, drilling, boring, gear machining, scribing, sawing, filing, scraping,

- Q:The difference between CNC machine tools and ordinary machine tools

- The other is all mechanical components, there is no automatic control system.

- Q:What is the CNC machine?

- The control system can logically process a program with control codes or other symbolic instructions and decode it, digitally represented by code, and input to the numerical control device through the information carrier.

- Q:What can a CNC lathe do?

- And how to ensure product stability.

- Q:CNC machine tools and general machine tools in the detection of the biggest difference between the machine

- In particular, CNC machine tools are now the general batch accuracy within 0.02MM, is difficult to proportion of ordinary machine!

- Q:How to categorize cnc lathes

- Metal cutting CNC machine tools

- Q:The type of lathe tool

- Lower (640 ° C or so) and steel friction, its wear resistance is poor.Therefore, can not cut steel, but in the difficult processing of materials or vibration of the special circumstances, because the cutting speed is not high, and the tool

- Q:CNC lathes 6140 and 6040 What is the difference

- Said floor and ordinary lathe, 1 said ordinary lathe (0 for the floor lathe), 40 is the machine main parameters, rotary diameter of 400 mm.

- Q:What is the main work of CNC machine tools?

- high flexibility. Processing objects change, generally only need to change the NC program, reflecting the good adaptability, can greatly save production preparation time. In the CNC machine tools, based on the composition can be more flexible automated manufacturing system-FMS.

- Q:What is the difference between CNC machine tools and general machine tools?

- 3, the spindle speed is high, the workpiece clamping safe and reliable.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Metrocopo Tile Forming Machine For Aluminum Coils with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products