Metallurgical Coke of Coke Strength after Reactivity 65

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Metallurgical Coke of Coke Strength after Reactivity 65 Description:

Coke is made by high temperature metallurgical coke for blast furnace smelting, casting and gasification. Occurring in the process of coking after recovery and purification of coke oven gas is a high calorific value of fuel, is an important industrial raw material in organic synthesis.

Coke is mainly used for blast furnace ironmaking and used for copper, lead, zinc, titanium, antimony, mercury and other non-ferrous metal smelting of blast furnace, reducing agent, compound and the function of stock column frame.

Blast furnace with Coke instead of charcoal, which laid a foundation for the large-scale of modern blast furnace, is a major milestone in the history of metallurgy.

2. Main Features of the Metallurgical Coke of Coke Strength after Reactivity 65:

• Quality assurance

• Mutual benefit

• Preferential price

• Various choice

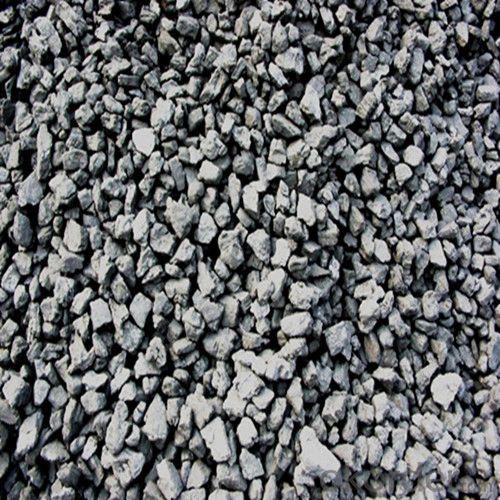

3. Metallurgical Coke of Coke Strength after Reactivity 65 Images:

4. Metallurgical Coke of Coke Strength after Reactivity 65 Specification:

Parameters | Guarantee | Rejection |

Total Moisture (As received basis) | 5% max | |

Ash (dry basis) | 12.5% max | > 13.5% |

Volatile Matter (dry basis) | 1.5% max | > 1.8% |

Sulphur (dry basis) | 0.65% max | > 0.75% |

Phosphorus (dry basis) | 0.035% max | > 0.045% |

M10 | 7% max | > 9% |

M40 | 84% min | <82% |

CSR | 65% min | <63% |

CRI | 25% max | > 27% |

Size 30-90 mm | 90% min | |

+90 mm | 5% max | > 8% |

-30mm | 5% max | > 8% |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

1) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2) What are coke's main physical properties?

The average heat capacity is 0.808 kj/(KGK) (100 ℃), 1.465 kj/(KGK) (1000 ℃)

Thermal conductivity is 2.64 kj/(MHK) (room temperature), 6.91 kj/(MHK) (900 ℃);

Ignition temperature (air) is 450-650 ℃.

3) How about your company?

Our company began to export coke when China cancelled 40% of coke export tariffs and quotas on January 1, 2013. We export many kinds of coke, such as CSR60 % and CSR 62% metallurgical coke (met coke), the NUT coke of 20 to 50 mm, coke breeze of 3 to 6 mm, and so on.

- Q:Import all carbide drill bit, mainly those brands

- Good (maford), Kenna, Thomas, di tex, Sandvik, guhring general in the domestic production, the performance of discount.Now on the market is generally a bit alloy steel material whole bit, although the materials are the same, but due to the processing technology, various brands of product quality disparity. Imported and domestic alloy drills are also very different.Imported alloy bit usually adopts VHM micro grain hard alloy (ISO K40), the type of ultrafine particles (0.6 m) in the application of high performance drill and ordinary milling machine, the hardness and toughness of the ideal together.Take high quality alloy bit surface coating, such as chromium aluminum nitride (AlCrN) coating, the coating layer of coating, the thickness of 4 m, the micro hardness is up to 3200HV, the friction coefficient of 0.35, thermal stability up to 1100 degrees celsius. After coating, the drill color is bluish gray.After coating, the alloy drill can process low alloy steel and high strength steel. High steel can reach 54HRC.

- Q:The use of cemented carbides YG and YT

- Two, titanium is a rare metal, characterized by light weight, high strength and good corrosion resistance. Because of its stable chemical properties, good resistance to high temperature, low temperature, strong acid, alkali resistance, as well as high strength and low density, has been praised as "space metal"". YT alloy and YW alloy have better properties than YG because they contain titanium.

- Q:Will the alloy produced at 400 watts be decarburization or carburizing?

- This is not necessarily, the hard alloy sintering infiltration decarburization mainly in wet grinding your ingredients and carbon sintering process control, vacuum furnace gas in order to prevent the reaction of pure, alloy with oxygen in the air, infiltration and decarburization products have no direct relationship, of course if it is caused by the leakage of vacuum sintering furnace can not meet the requirements, will lead to the direction of decarburization alloy.

- Q:Carbide drills and cobalt high speed steel bit, which is good? What's the difference between these two materials?

- The two materials are not good or bad, the key is to look at the application!!Carbide drill, high hardness, wear resistance, high efficiency, toughness slightly worse, therefore, the rigidity of the machine tool and spindle runout and speed are required!Cobalt high speed steel including ordinary high-speed steel, good toughness, edge processing can be very sharp, more suitable for processing some sticky materials, of course, low strength materials will be nothing difficult, but its high temperature resistance, wear resistance is relatively poor, the drilling speed is not high!!Therefore, the choice of drill or according to your working conditions to choose,

- Q:What materials are hard alloys used to process?

- YT hard alloy, resistant to impact, high temperature, processing steel, aluminum and so on.

- Q:K carbide carbide cutting tools, mainly used for turning what materials?

- Suitable for processing stainless steel, non-ferrous metals, non-metallic materials, cast iron and so on

- Q:What kind of cemented carbide is used for processing HRC40 degrees stainless steel?

- This kind of hardness stainless steel is martensite, hardness is high, use tungsten cobalt class (do not use tungsten, cobalt, titanium, this is attention 1), and carbide containing Ta. Such as: YA6, YH1, YW3, etc.. This kind of steel is of high hardness, small feed rate, lower cutting speed, greater cutting depth, and avoiding the work hardening of the surface leather and the front working procedure (Notice 2). Machine tools. The steel of the tool is better. The coolant selects viscous and chlorine - containing cooling liquid with good adhesion and cooling performance. (Note 3)

- Q:Can CBN wheels grind cemented carbide? Why?

- Tungsten carbide and non-metallic ceramic materials are usually made of diamond grinding wheels.CBN can iron group elements of workpiece.According to the development trend of ordinary abrasive abrasive, > superhard abrasiveCorundum like A - >CBN BSilicon carbide C> diamond DThe rule: A sends to B, C develops D

- Q:Why is carbide cutting tools less standard than high speed steel cutting tools?

- Because carbide cutting tools wear better than high speed steel cutting tools.

- Q:Welding hard alloy cutter, hard alloy cutter, high speed steel, ceramic knife head head are what are the advantages and shortcomings?

- The advantages of carbide drill can drill more hard material, the disadvantage is to be good grinding, grinding is not good, easy to break the edge, two main cutting edge height and angle equivalent, it is best to use the grinding machine.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Metallurgical Coke of Coke Strength after Reactivity 65

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products