Metallic Coated Aluminium Coils Used for Aluminium Composite Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Metallic Coated Aluminium Coils Used for Aluminium Composite Panels

Metallic coated aluminium coils are processed through t roller coating and baking with precise polyester paints.

Its color is glossy and with variety colors. Chromatic aberration is small, impact resistance is strong and easy to be processed, and all its performance has reached or surpassed the national criteria. The products are widely used in indoor and door decoration, ceilings, room surface tiles, corrugated boards, wall panels, advertisement boards, counters, home appliances, decoration in and out of autos and boats.

2. Main Features of Metallic Coated Aluminium Coils Used for Aluminium Composite Panels

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

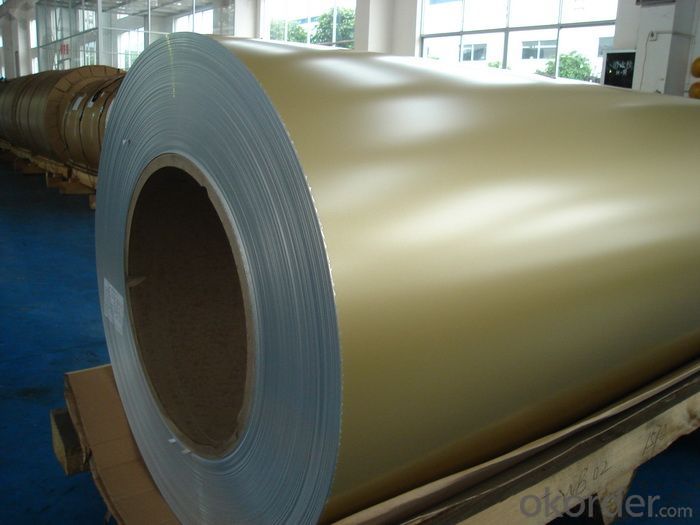

3. Metallic Coated Aluminium Coils Used for Aluminium Composite Panels Images

4. Specification of Metallic Coated Aluminium Coils Used for Aluminium Composite Panels

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:Can aluminum coils be recycled multiple times without losing their properties?

- Yes, aluminum coils can be recycled multiple times without losing their properties. Aluminum is a highly recyclable material and can be melted down and reused indefinitely without any significant degradation in its properties. This makes aluminum coils a sustainable and environmentally friendly choice for various applications.

- Q:The canoe is aluminum. It has some paint remaining on it from what i am assuming is the original factory paint. The paint is just in patches, so my question is do i sand only where the paint is, or the whole canoe? Will sanding the aluminum damage it? Or should I not sand it at all, and just use paint stripper? After getting the old paint off, what kind of primer should i use? or is it not necessary to prime? What kind of paint should I use? I plan on it being multi tone(a leafy camo, of olive drab, flat black, and a gray tone).

- Pete is on the right track, but I think that rather than primer, what you need is to wash the aluminum with acid after you use a chemical stripper to get the paint off. The acid dissolves the layer of corrosion that all aluminum gets with exposure to air and also gives the fresh primer something to adhere to. You can lightly sand aluminum by hand or with a random orbit sander, but aluminum dust has been linked to alzheimer's disease so wear a good mask. But if your canoe has a lot of paint still on it or a lot of rivets and seams, then a stripper made for aluminum will save you a lot of time and effort. Go to a place that specializes in paints and finishes specific to the boating, recreational vehicle, or trucking industries as they deal with aluminum all the time and have the specialized products that you need in order to refinish and repaint it because it isn't like steel or wood and requires specific formulations. If you try to skip a step or buy the wrong stuff, your efforts will probably not succeed because working with aluminum is unlike any other material. Read and follow all directions and safety instructions carefully because the chemicals involved are strong and can give off toxic fumes. Because most things made from aluminum are subject to a wide variety of climates and rough handling, you need to buy products that are specially formulated for it and follow the steps and safety precautions exactly or all your hard work will probably be for naught.

- Q:Are aluminum coils resistant to oil and grease?

- Yes, aluminum coils are generally resistant to oil and grease.

- Q:Are aluminum coils suitable for insulation jacketing?

- Yes, aluminum coils are suitable for insulation jacketing. Aluminum is a highly durable and corrosion-resistant material that can effectively protect insulation materials from external elements. Additionally, aluminum coils offer excellent heat and moisture resistance, making them an ideal choice for insulation jacketing applications.

- Q:Are there any specific maintenance requirements for aluminum coils?

- Yes, there are specific maintenance requirements for aluminum coils. Aluminum coils are commonly used in HVAC systems and require regular cleaning and maintenance to ensure optimal performance and longevity. Some of the maintenance requirements for aluminum coils include: 1. Cleaning: Regular cleaning of aluminum coils is necessary to prevent the buildup of dirt, dust, and other contaminants. This can be done using a soft brush or a vacuum cleaner with a brush attachment. It is important to clean both the fins and the surface of the coils to ensure proper airflow. 2. Inspection: Regular inspection of aluminum coils is essential to identify any signs of damage or corrosion. Look for any bent fins, leaks, or signs of wear and tear. If any issues are detected, they should be addressed immediately to prevent further damage. 3. Coil Protection: Applying a protective coating to aluminum coils can help prevent corrosion and extend their lifespan. There are various coatings available in the market specifically designed for aluminum coils, which can provide an additional layer of protection against environmental factors. 4. Air Filter Maintenance: The air filters in HVAC systems play a crucial role in maintaining the cleanliness of the coils. It is important to regularly clean or replace the air filters to prevent the accumulation of dust and debris on the coils. Clogged filters can restrict airflow and reduce the efficiency of the system. 5. Regular Maintenance Schedule: Creating a regular maintenance schedule is essential to ensure that all necessary maintenance tasks are performed on time. This can include cleaning, inspection, and any other specific requirements recommended by the manufacturer. It is important to consult the manufacturer's guidelines and recommendations for specific maintenance requirements for aluminum coils, as they may vary depending on the type of system and application. Following these maintenance requirements can help ensure that aluminum coils function efficiently and have a longer lifespan.

- Q:How are aluminum coils protected from corrosion?

- Aluminum coils are protected from corrosion through various methods and coatings. One common method is anodizing, which involves immersing the coils in an electrolyte solution and passing an electric current through them. This process forms a thick oxide layer on the surface of the aluminum, providing excellent corrosion resistance. Another method is the application of a protective coating. Aluminum coils can be coated with organic or inorganic coatings, such as polyester, epoxy, or polyvinylidene fluoride (PVDF). These coatings act as a barrier, preventing moisture and corrosive substances from reaching the aluminum surface. Additionally, aluminum coils can be protected through the use of sacrificial coatings. This involves applying a layer of a more reactive metal, such as zinc or magnesium, onto the aluminum surface. These sacrificial coatings corrode before the aluminum does, effectively protecting it from corrosive elements. Regular cleaning and maintenance also play a crucial role in preventing corrosion. Accumulated dirt, debris, and corrosive substances should be regularly removed from the surface of the coils to maintain their corrosion resistance. Overall, a combination of anodizing, protective coatings, sacrificial coatings, and proper maintenance ensures that aluminum coils are effectively protected from corrosion, extending their lifespan and maintaining their performance.

- Q:Can aluminum coils be used in the production of beverage cans?

- Certainly, beverage cans can indeed be produced using aluminum coils. Aluminum is the preferred material for manufacturing beverage cans due to its lightweight nature, durability, and ability to maintain the taste and quality of the contents. Typically, aluminum coils are employed in the canning process as they can be readily molded into the desired can shape. These coils are rolled into sheets, which are subsequently cut and transformed into cans. Additionally, aluminum coils possess exceptional heat conductivity, enabling efficient cooling and faster production rates. All in all, aluminum coils play a crucial role in the production of beverage cans and are extensively utilized within the industry.

- Q:What are the different coil leveling options available for aluminum coils?

- There are several coil leveling options available for aluminum coils, including tension leveling, temper leveling, and stretcher leveling. Tension leveling involves stretching the coil to remove any shape defects and improve flatness. Temper leveling involves subjecting the coil to controlled heating and cooling cycles to relieve internal stresses and improve flatness. Stretcher leveling involves stretching the coil beyond its yield point to permanently remove shape defects and improve flatness. These different options allow for customized leveling techniques based on the specific requirements of the aluminum coil.

- Q:I take an extracurricular aircraft class, and I got the okay to take some old painted sheet aluminum for another project I'm working on. The problem is, what I'm using it for I need bare aluminum. I heard around that air crafts are painted with something that regular (store-bought) paint stripper can't remove. Is this true? I am aware of the fact that stripping something like that will result in a toxic paint sludge, so I've taken precautions for that. I just need to know if heavy-duty paint stripper from Home Depot will do the job. Thanks :)

- It depends on how old the paint is. If your panel was painted before the 1970's, then pretty much any chemical paint stripper will work. After the 70's, they started using epoxy based primers and paints and those are more resistant to chemical strippers. In any case, wear rubber gloves and breathing protection while using chemical paint strippers. They can burn your skin and create toxic fumes when in use.

- Q:I have a broken exhaust stud in my engine head. I have an aluminum head but the stud is steel. The stud broke a little below the surface. I want to mig weld a washer to the stud, but will the weld stick to the aluminum or will it blow a big hole in the head? I will only be using a little 110 mig welder.will I be okay or will that lead to more problems?

- Drill out the stud, extract the broken stud, refresh the threads and install a new stud. You'll ruin the head if you attempt to weld.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Metallic Coated Aluminium Coils Used for Aluminium Composite Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords