Metalized OPP Laminated AL Used For Packing In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

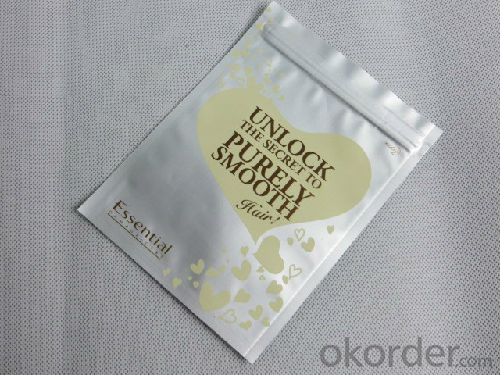

1. Description of Metalized OPP Laminated AL Used For Packing In Food Industry:

Metalized OPP Laminated AL Used For Packing In Food Industry are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Metalized OPP Laminated AL Used For Packing In Food Industry mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Metalized OPP Laminated AL Used For Packing In Food Industry:

Excellent quality control

Experienced factory produced

SGS passed

3. Metalized OPP Laminated AL Used For Packing In Food Industry Photos:

4. Metalized OPP Laminated AL Used For Packing In Food Industry Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Metalized OPP Laminated AL Used For Packing In Food Industry:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:Printing solvent for food packing bag

- Determine the amount of water in the solvent by means of the principle of a different dissolution effect. Take the most transparent glass cylinder tube with 100ml toluene solution, take a small amount of analyte ester solvent such as toluene, evenly pour. When you just pour in toluene, carefully observe whether there is turbidity (milk white) phenomenon. If there is this phenomenon, the water content of the solvent is seriously exceeded, and the experience shows that when the moisture content exceeds 0.5%, the phenomenon is obvious. The water content test of benzene solvent can be carried out by extracting solvent from the long glass tube to observe whether there is delamination.

- Q:What material should be used for transparent packing bags? How many cents do you want?

- PVC products for packaging containers, mainly for a variety of film and film. PVC containers mainly produce mineral water, drinks and cosmetics bottles, as well as packaging for refined oils. The PVC film can be used in CO extrusion with other polymers to produce low cost laminates and transparent articles with good barrier properties. PVC film can also be used for stretch or heat shrink packaging, used for packaging mattresses, cloth, toys and industrial goods.

- Q:What does "13 silk" in vacuum packing bag mean?

- Silk is a mechanical worker, commonly known as "0.01 millimeters", the workers who have inherited the technology of Shanghai say "silk", and in the north they say "0.01 millimeters" as "Dao".

- Q:Can food wrap be heated in a microwave oven?

- It depends on the label on the package. If it can be marked with microwave heating, you can not.

- Q:How are food bags made out?

- Packaging design: This is based on the requirements of the food company to design the layout of the food packaging bag, that is, the pattern of food packaging bags. A good design layout of food packaging bags can improve the sales of products. After all, the first eye is still very important. This pattern is generally designed by the food company and then given to the manufacturer of the bags.

- Q:What is the material of detergent bag?

- Polyethylene (polyethylene, referred to as PE) is a thermoplastic resin made by polymerization of ethylene. Industrially, it also includes copolymers of ethylene with a small amount of alpha olefins. Polyethylene is odorless, non-toxic, feel like wax, has excellent resistance to low temperature performance (minimum temperature up to -100~-70 degrees C), good chemical stability, erosion resistance to most acid-base (not resistant to oxidizing acid). At room temperature, insoluble in general solvents, low water absorption, good electrical insulation.

- Q:How do you determine the 210mm*300mm package and determine its version and length?

- Length 21 cm, width 30, vertical roll length suggest up to cooperate with compound printing equipment

- Q:How big is the vacuum pack 28*40cm?

- 28*40CM is the size of a vacuum packed bag, 40 cm long and 28 cm wide

- Q:What are the soft and hard sides of plastic bags? Material or process technology?

- On the basic price will be a little higher, the brittle is generally PP or PET is done, some relatively low grade. Soft is generally made of multi-layer coextrusion film, barrier, and feel good. This soft about 27000 yuan / ton, while the PP film generally as long as 17000 yuan / ton, ten thousand tons a difference.

- Q:What are the characteristics of a good package?

- This mainly refers to the packaging can perfectly protect and preserve the goods in the design of material selection, structure, can effectively cooperate with transportation storage loading and unloading circulation operation; enable consumers to use the goods, carrying and preservation is more convenient. In addition, whether the packaging material will cause pollution to the environment, and whether recycling is also very important. Packaging industry is a scientific and systematic project, and the packaging design must take into account the scientific aspects of each link, which also reflects the combination of art and science characteristics.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Metalized OPP Laminated AL Used For Packing In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords