Metal T Bar home T-GRID CEILING SUSPENSION

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized s

teel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic

cold roll forming and punching machineries guarantee the high precision.

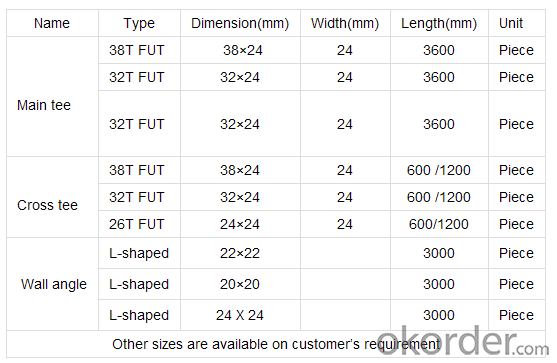

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized s

teel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic

cold roll forming and punching machineries guarantee the high precision.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

- Q:What are the meanings of the letters in the CB, DB CS, DF DM of the light steel keel? Seeking different people to explain ah

- (50 * 19 * 0.5, 50 * 20 * 0.6, 60 * 27 * 0.6), DB: Ceiling keel is not on the people (including the ceiling bearing keel: 38 * 12 * 1.0 and ceiling cover keel)

- Q:I have a school project and i can get extra credit if i do it on a ceiling tile that will be hung in class, so to all contractors,or people that just know the answer please answer as fast as you can!

- If you mean the drop-in tiles that fit into the metal grids, there are 2 sizes, 2ft x 2ft. and 2ft. x 4 ft. You can get them at lowes or home depot.

- Q:Is it nice to use a light steel keel or a wooden keel?

- Of course, is the light steel keel, you can choose DU50 system ceiling keel, carrying keel thickness of not less than 1.0mm (GB 1.2), cladding keel thickness of not less than 0.45mm (GB 0.5)

- Q:In the interior decoration of light steel keel plus gypsum board on the basis of the network can not be approved?

- I said is the light steel keel wall tiling construction process, now the pressure of cement with self-tapping fixed to the wall, in the above with a scraper to the cement put the water putty putty hanging on the cement pressure plate, pulled into a burr Type of this can be easy to hang steel mesh, and then finished with cement mortar leveling tiles. I have been very detailed.

- Q:Light steel keel wall height of more than 4 meters when to use what reinforcement measures, who can provide node installation map?

- It depends on what kind of space you do in the partition is the last to do a fulcrum with a keel to do the bracket attached to the top of the top If you are out of the wall to do the room is in the top of the room with each other keel support up to the most of this time you'd better use thick vertical keel do not know can help you

- Q:Tooling, specifications have no provisions Light steel keel ceiling to brush fire paint?

- Do not use light steel is the thickness of 0.5 1.0 galvanized steel strip

- Q:Light steel keel wall hidden acceptance of what is the hidden content? (Not a ceiling)

- 1, whether the work of the wall itself in place. 2, pipe installation within the wall is in line with specifications. 3, whether the sound insulation placed in line with the requirements.

- Q:Light steel keel wall noise cotton is asbestos it? Are there any harm?

- Yanmian products are used high-quality basalt, dolomite as the main raw material, after 1450 ℃ high temperature melting after the use of international advanced four-axis centrifuge high-speed centrifugal fiber, while spraying a certain amount of binder, dust, After the collection by the collection of cotton, through the pendulum method, coupled with three-dimensional method of cotton after the curing, cutting, the formation of different specifications and use of rock wool products. Rock wool is a skin irritating cotton product, direct contact with the skin is caused by irritation, such as redness, itching and so on. Other hazards are temporarily unknown. Yanmian advantage lies in the safety of fire, heat insulation sound insulation. Such as other mineral batons are of this nature. If you are worried about sound insulation cotton hazards, you can use polyester fiber sound-absorbing cotton, is currently the most widely used safety and environmental protection sound insulation batt.

- Q:Φ8 light steel keel boom is how much?

- Do pull the experiment to know the top burst out of the boom will not break off In the beam generally around 300KG

- Q:Here is what I have...a wire that looks like a regular cord for a plug in and a copper looking wire I assume is the ground. In the drop ceiling I have two wires that seem to have been been cut from electric cord and hard wired into another track lighting. I have had a light up here before but have not ever previously hooked electric up. I know it can handle the electric current. There are caps at the end of the wires so I am assuming (love assuming) that I can attach the wires from the light to these wires and recap. Then I need to ground the cooper wire, but what is a good ground? It is a drop ceiling so can I attach to the grid or wires holding the drop ceiling? Of course the electric will be off! I am wondering is it possible to cross the two wires and have a big boo boo happen? I appreciate the input. I am really needing to get this completed shortly so please anyone with some expertise respond!

- with common lighting you cant go wrong.black wire is Hot or + or supply.white is neutral.neutral is the same as a ground.people will try to explain it differently but the ground and neutral are married in the fuse box.if the wires are crossed the lite wont know it.just attach ground to the mounting box it's incidental to your purpose

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Metal T Bar home T-GRID CEILING SUSPENSION

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords