Metal Studs, Ceiling Drywall Metal Stud.

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

C channel metal stud sizes/decorative metal studs/drywall metal stud sizes

Features:

(1)Lightweight to carry and handle.

(2)High-quality steel: its surface is smoothness and it hard to distortion.

(3)Rust- proof and Corrosion- resistant: High Zinc Coating of 100 g/m2.

(4)New-type earth-friendly products: galvanized steel-no radiation, not

hazardous material, not pollute the environment.

Ceiling Channel for ceiling system

1. Supporting channel: 38 x 12mm, 30 x 27mm, 50 x 12mm, 50 x 15mm, 60X27mm

2. Covering channel: 50 x 19mm, 60x 27mm

3. Length: 2. 7mm, 2. 8mm, 2. 9mm, 3. 0mm

4. Supporting channel: 0. 5mm, 0. 6mm, 0. 8mm, 1. 0mm, 1. 2mm

5. Covering channel: 0. 35mm, 0. 4mm, 0. 45mm, 0. 5mm, 0. 6mm

6. Wall angle: 25 x 25 x 0. 4mm / 0. 5mm / 0. 6mm

Packing: 10pcs in bundle

3.Image

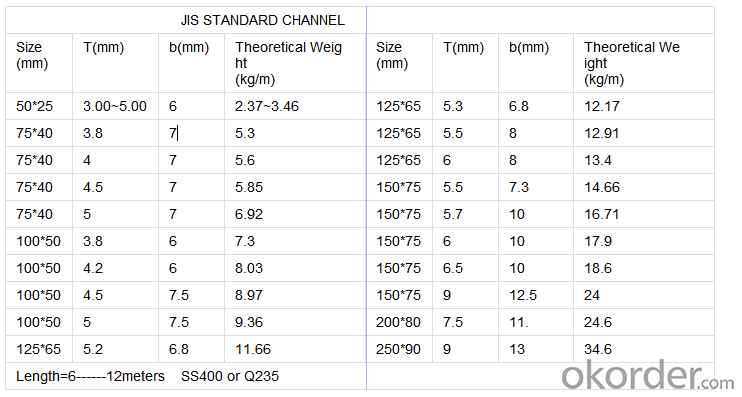

4.Detailed Specification

5.FAQ

Stud and track for partition wall

1. Stud size: 50 x 45mm, 50 x 40mm, 50 x 35mm, 75 x 25mm, 75 x 35mm, 75 x 45mm, 100 x 45mm

2. Track size: 50 x 40mm, 50 x 35mm, 75 x 30mm, 75 x 40mm, 100 x 40mm

3. Length: 2. 7mm, 2. 8mm, 2. 9mm, 3. 0mm

4. Thickness: 0. 35mm, 0. 4mm, 0. 45mm, 0. 5mm, 0. 6mm

All sizes and shapes of steel channels are available

The light steel keel material has very well mechanical property, high precision on size, well linearity, flat panel. It is ametabolic and it can avoid cranny causing by ceiling installation.

Fixity is very good during installation, with unique pocked technique. It is good for avoiding selftapping screw sidesliping. It not only improve the speed of construction, but also assure the locked-in connection among materials.

- Q:75 light steel keel wall to do 6m high, need reinforcement? How to strengthen?

- Must do 75 keel, it is recommended to add angle iron or square tube reinforcement, do not forget to do heart keel

- Q:6 meters high ceiling to do 4 meters with light steel keel do wall light steel dragon skeleton is to do 6 meters to the top or do high

- It is best to do the top, or else do the ceiling to do the wall can also be done,

- Q:Light steel keel partition wall construction process is what

- Fixed Border keel: Border keylone along the position of the ball, the edge of the keel should be coincident with the elastic line. The end of the keel should be fixed, fixed point spacing should not be greater than lm, fixed should be solid.

- Q:What is the relationship between the base board and the liner, whether the keel is between the two layers? Such as light in the wall to do soft package, the basic board and liner how to connect?

- In fact, the soft bag is not soft package, sponge package in a 9mm Austrian Song board, this is the soft bag, and then in order to fixed on the wall, in the light steel keel wall to do a lining you said, That is, I mentioned above the blockboard base.

- Q:How to install light steel keel gypsum board wall

- Door and window frame according to the design position in place, with the vertical keel, along the ground, along the top keel connection. Wooden window frames can be fixed with wooden screws, steel, aluminum alloy door and window frames can be fixed with self-tapping screws.

- Q:Will the light steel keel, brick block, light partition wall do inside the wall what are the advantages. Including the price, as much as possible, thank you!

- The Brick block from the weight of large, said to do on the floor will increase the load on the building, upstairs is not convenient. Light wall panels are similar to light steel keel partitions. Is the price or light steel keel cheap. I do light steel keel project, and now plant, office buildings are using this.

- Q:Light steel keel partition wall fire retardant coating shabu several surface

- Best four times, at least twice. I hope my solution will help you

- Q:4 m long prefabricated board can do light steel keel double gypsum board wall?

- Yes, the gypsum board partition wall is not much weight, far less than the prefabricated board capacity

- Q:How to do woodworking partition wall, with door

- Wood keel partition wall is made of red, white pine do skeleton, gypsum board or wood fiber board, plywood for the panel of the wall, its processing speed, low labor intensity, light weight, sound insulation effect is good, widely used.

- Q:How to remove the gypsum board cut off

- To deal with the local property, to understand the removal of the area to be noted, such as the demolition of the mall will be sealed room, so that the impact of dust and garbage next door store business. And the parties to deal with more, will facilitate the back of the work.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Metal Studs, Ceiling Drywall Metal Stud.

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords