Metal Stud / Metal Track Gypsum Light Steel Profile For Gypsum Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Drywall partition Hot dipped zinc galvanized stee strip zinc coating is 40-180g/m2.good quality and competitive price

Item Name:furring channel

Size: 68*35*22mm

Thickness:0.4-0.8mm

furring channel Surface:Zinc Galvanized

Item name: furring channel

furring channel Thickness:0.4-0.8mm

Surface:Zinc Galvanized

Furrring channel Packing: Clear tape, 20pcs/bundle

furring channel Technicology:adopting high-grade quality hot-dipped galvanized steel,The products surface zero spangle,and intensity toughness, besides, it can add 20% more than common.

Advance equipment make sure the high quality, the steel profile surface zinc coating is shipping, shape correctly, size exactly. And good reputation in oversea market.

3.Image

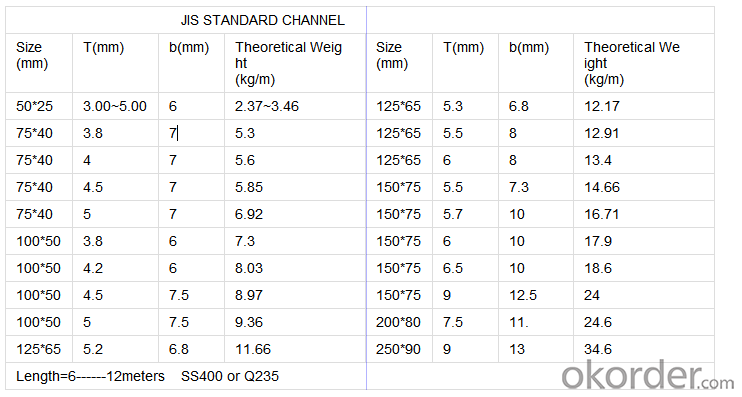

4.Detailed Specification

5.FAQ

Advantages of Galvanized Steel Profile:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirments.

5. Advanced equipment can make sure exactly size, high quality products.

Applications

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc..

C metal stud is faced with plasterboard

U metal track is installed along the floor to fix metal stud

- Q:Who used the light steel keel gypsum board to do the wall?

- Not compare province, province, then you buy bricks more province, just better installed than brick light

- Q:6 meters high ceiling to do 4 meters with light steel keel do wall light steel dragon skeleton is to do 6 meters to the top or do high

- It is best to do the top, or else do the ceiling to do the wall can also be done,

- Q:To warm the above has been tiled, with light steel keel to build a wall, how to fix the keel?

- With C-beam or two angle steel, LI put two and wall fixed, the keel fixed to the LI. Do not be able to drill on the ground.

- Q:What is the relationship between the base board and the liner, whether the keel is between the two layers? Such as light in the wall to do soft package, the basic board and liner how to connect?

- In the original wall to do single-sided light steel keel wall, blockboard base, the installation of aluminum alloy hanging, and then soft package fixed on the bar.

- Q:The walls are light steel keel gypsum board partition, the property requirements can not move, but I would like to do a word on the wall shelf, how construction?

- How to get someone else, please eat a meal, or simply do not thousands of dollars that deposit

- Q:Light steel keel gypsum board partition wall brush black latex paint, I would like to change the brush blue latex paint, how to deal with grassroots?

- I am a decoration worker, painter, there are a few details you need to add 1, before the black latex paint is how long to sit? 2, there is no grass-roots off, loose phenomenon? 3, need to transform the home improvement? Or tooling? Because each has a processing method? Need to be added to determine your home to change how to deal with the grassroots, gypsum board in addition to the degree of solidarity you can rest assured that the situation is not damp its structure is still very high!

- Q:Waterproof gypsum board for toilet partition and paste tile installation steps?

- The exterior wall of the bathroom is made of ordinary type gypsum board (size 1.2M * 3.0M). Can be fixed with pneumatic nails, can also be used 4 * 20 anti-rust self-tapping screws.

- Q:Now what is the room wall material is fashionable? Environmentally friendly

- Sound insulation cotton how to be environmentally friendly too old and toxic The best material is lightweight partition wall insulation insulation and non-toxic light foam cement board wallboard calcium silicate partition board and keel plus paint-free green frog Non-toxic dalfers are currently my best found some non-toxic

- Q:Light steel keel + gypsum board wall and other wall joints how to strengthen?

- It is recommended to use high-quality glass glue, if the cracks in the 1cm below, often contact with water, it is recommended to buy auto repair sealant effect is particularly good.

- Q:How to do woodworking partition wall, with door

- Wood keel partition wall is made of red, white pine do skeleton, gypsum board or wood fiber board, plywood for the panel of the wall, its processing speed, low labor intensity, light weight, sound insulation effect is good, widely used.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Metal Stud / Metal Track Gypsum Light Steel Profile For Gypsum Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords