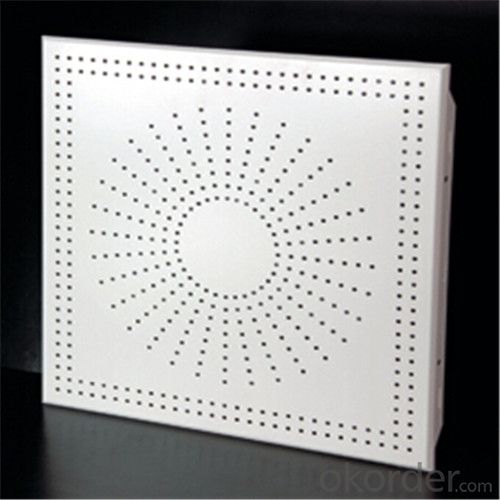

Metal ceiling clip in type perforated aluminum

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Clip in aluminum ceiling, an ideal modern interior decoration material . Plain or pattern can be selected according to the actual requirement.

Description

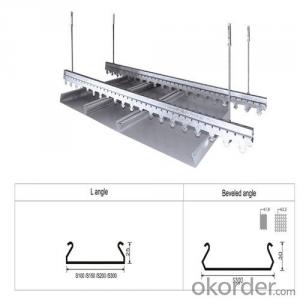

Clip in system which is concealed, steady structure, flat surface, could be both used as ceiling and wall panel. It is widely used for decoration in airports, railway stations, waiting room, subway stations, commercial buildings, shopping malls, hotels and other types of entertainment places.

Specifications

Our cmax square ceiling series include:plan square ceilings,down-level ceilings,combination ceilings,perforated ceilings.

Application

Cmax aluminum square ceilingcan be widely applied for office,shopping mall,conference room,laboratory and exhibition hall.

Features

1.Rgulated shape

2.Beauty

3.Elegance

4.Widen vision

5.Easy installation

6.Easy cleaning

Square Ceiling series

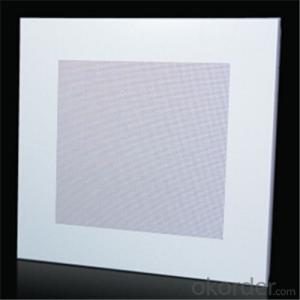

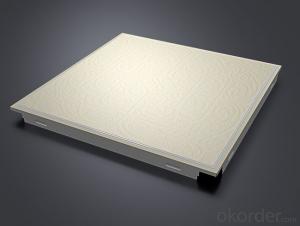

1.plain square ceiling

2.down-level ceiling

3.combination ceiling

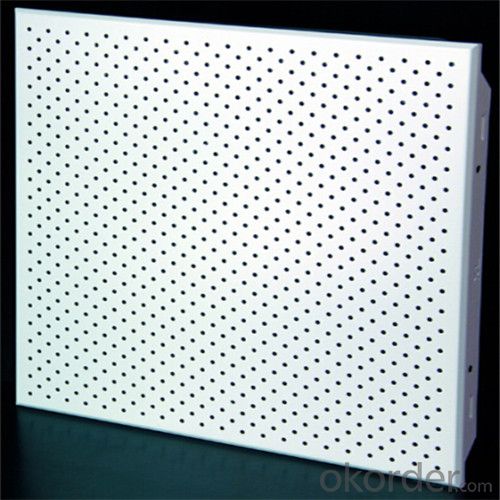

4.perforated ceiling

Base material

Aluminum alloy ,the gread of aluminum alloy can be selected according to the actual requirements.

Type of surface

Surface venner:Power coating(ordinary power,polyester),rolling,laminating,metal anode oxidation treatment.Can be pore panel or punching panel according to the actual requirements.

Sizes

specication(mm) | thickness of base panel(recommendation) |

300*300 | 05mm |

400*400 | 0.6mm |

600*600 | 0.7mm |

300*600 | 0.6mm |

600*1200 | 0.9mm

|

Item name | Aluminum ceiling |

Brand name | CMAX |

Material | Aluminum or Aluminum alloy |

Size | 300x300, 300x600, 600x600,600x1200mm…customized |

Thickness | 0.4-0.8mm,on request |

Height | 17mm,20mm |

Coating | Powder coating,polyester powder coating(10 years guarantee) |

Color | White, blue, pink, yellow...customized |

Feature | Easy install and disassemble,simple structure,good adhesion,anti-corrosion, fireproof,waterproof,rust proof,weather resistance,easy cleaning,sound absorbing, heat insulation, highly recyclable,good plasticity,easy maintenance, durable,anti-ultraviolet, radiation proof… |

Package | Standard carton with mark, the carton size: 620x320x320mm, 60 pcs per carton. |

Certificate | ISO9001:2000 |

Application | Kitchen,bathroom,living room,office,shopping mall,conference room,laboratory,exhibition hall,airport and so |

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:What are the properties of aluminum?

- Aluminum heaters are often used to melt refractory metals and welded rails. Aluminum is also used as a deoxidizer in the process of steelmaking. Aluminum powder and graphite, titanium oxide (or other high melting point metal oxide) according to a certain ratio of uniform mixing, coated on the metal, the high temperature calcination and made of high temperature resistant cermet, it has important applications in rocket and missile technology The

- Q:Aluminum slab ceiling and mineral wool board ceiling which is better and more expensive

- Aluminum slabs are usually used in home improvement market. Because it is generally used in the kitchen bathroom, when used the most important concern is the effect of oil and water. Aluminum slab plate, especially the roller coating of the durability effect is better mineral wool sheet is mainly used in the engineering market.

- Q:Kitchen and bathroom ceiling, is the aluminum plate is good? Or waterproof gypsum board is good? What are their advantages and disadvantages?

- Cheaper point of the aluminum slab board than gypsum board wall aluminum slab board victory gypsum board do not consider

- Q:Do you need to buy expensive?

- As long as it is a molding. Not posted the pattern of the line. You buy the cheapest I promise as long as no earthquake you do not change this life you do not have to worry about it bad friends

- Q:Under the beam to install aluminum hanging plate ceiling, at least need to stay a few centimeters? (That is, the distance between the aluminum plate and the beam)

- Stay 6 cm on it. Because the aluminum slab board construction from the keel hanging down, there are 6 cm space to buckle down.

- Q:It is good for the film and the film

- Rolling metal products: Roller metal ceiling is the use of Southwest Aluminum produced by the hot-rolled high-quality aluminum alloy plate as the substrate, the surface selection of imported PVDF fluorine or PE coating, the professional roller production line from the rolling, the product has attached Strong strength, acid and alkali resistance, resistance to decay, resistance to ultraviolet radiation and other characteristics. Variety of colors to allow customers to choose, can also be customized according to the desired color.

- Q:How to clean the kitchen aluminum plate.

- Aluminum plate is relatively easy to clean, generally clear with a cleaning agent, and then clear it again on the water, the detergent must use a neutral, can not use salty and acidic.

- Q:I have any part of the color of the ceiling of the aluminum plate

- This phenomenon is a lot, mainly with oil and then dust. The If you will be removed to clean or very much, first diluted with oxalic acid, brush with a brush to brush after washing with water as new

- Q:Are there any differences between the ceiling and the Laminates? Is the price the same?

- As long as the plate material is aluminum, all called aluminum plate. Laminating plate, refers to the main material outside the adhesion of a layer of protective material. There are many kinds of laminating plates, the mainstream of the film board containing PVC coated board and aluminum slab plate coated two. Laminated film because of their own technical limitations, inevitably there will be a bubble phenomenon, this is absolutely unavoidable. At the same time according to the difference between the film material, poor material turned yellow year, a good material for three years will change color. So now the mainstream products are the main roller-based, laminating board has not been accepted by everyone.

- Q:What is the characteristic of the ceiling plate?

- The aluminum plate is the most suitable decorative material for kitchen and bathroom ceiling applications. Has a good moisture, anti-oil, flame-retardant features, nice, easy to transport and use. Aluminum buckle board advantages: 1. Has a very good corrosion resistance, to resist a variety of fumes, humid environment, anti-ultraviolet. 2. Environmental protection, non-toxic and tasteless, anti-static, no dust, easy to wash. 3. High hardness, fire, non-stick stain 4. Low cost, China's high-end integrated ceiling are used aluminum plate material, longer life, and not easy to sink, discoloration deformation. Aluminum buckle plate Disadvantages: 1, the installation requirements are high; 2, patchwork as steel. 3, plate type, style, no steel and more.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Metal ceiling clip in type perforated aluminum

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords