Mesh Green Vinyl Coated Hardware Cloth with Differnent Gauges

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mesh Green Vinyl Coated Hardware Cloth with Differnent Gauges

1. Structure of Mesh Green Vinyl Coated Hardware Cloth with Different Gauges Description:

Mesh Green Vinyl Coated Hardware Cloth with Different Gauges is made of high quality steel wire, Various configurations and sizes, Suitable for shotcrete applications, constructed with galvanized iron wire of high quality. It has PVC powder covering that is processed by an automatic machine. The smooth plastic coating on this corrosion protective wire is attached with a strong adhesive which make increases durability of the wire.

Mesh Green Vinyl Coated Hardware Cloth with Different Gauges is mainly for the animals fence, supermarket shelves, interior decoration, poultry, flowers and trees fences, outdoor for villas, residential segregation wall, the product has a distinctive color, beautiful, corrosion and rust, fade, UV and so on.

2. Main Features of Mesh Green Vinyl Coated Hardware Cloth with Different Gauges:

• Age residence

• Antirust

• Durable

• Beautiful shape

• Good anti-corrosion

• Easy installation

3. Mesh Green Vinyl Coated Hardware Cloth with Different Gauges Images

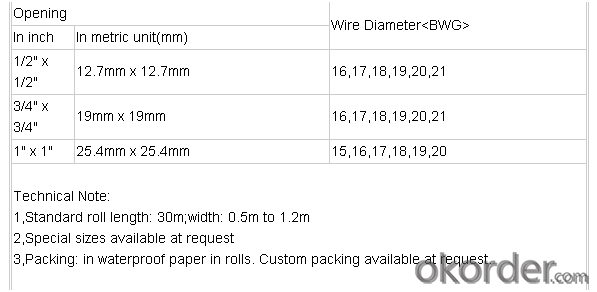

4. Mesh Green Vinyl Coated Hardware Cloth with Different Gauges Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Mesh Green Vinyl Coated Hardware Cloth with Different Gauges?

Our company is the professional manufacture of Mesh Green Vinyl Coated Hardware Cloth with Different Gauges and any other wire mesh. We have more than 15years experience in producing welded wire mesh. Based on our experience, with our reasonable price, high quality and considerate service, our products enjoy high reputation in our market. Our main products like Mesh Green Vinyl Coated Hardware Cloth with Different Gauges, hot rolled steel plate/coil, cold rolled steel coil, gi steel coil, pp gi coil, corrugated sheet, wire rod and so on. We have established business relationships with clients in the Southeast Asia,South Asia, North America, and many other countries and regions.

②The reason why you choose us

· Diversification of products

. Professional sales team

· Industry experience over 15 years

· Shipment of goods -More than 50 countries worldwide

· We have the most convenient transport and prompt delivery

· We offer competitive price with best service

· We have win high reputation based on best quality products

③How long can we receive the product after purchase?

In the purchase of Mesh Green Vinyl Coated Hardware Cloth with Different Gauges within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q:Can steel wire mesh be used for stone retaining walls?

- Yes, steel wire mesh can be used for stone retaining walls. It can provide added strength and stability to the structure, helping to prevent the stones from shifting or collapsing. The wire mesh is typically installed within the wall, acting as a reinforcement and holding the stones together.

- Q:What are the different finishes available for steel wire mesh?

- Steel wire mesh comes in various finishes, each with unique features and advantages. Let's explore the different options: 1. Galvanized Finish: To protect the steel wire mesh from corrosion, a layer of zinc coating is applied. This finish is ideal for outdoor applications or environments with high humidity and exposure to chemicals. 2. PVC Coating: To enhance durability and resistance to abrasion, corrosion, and UV rays, the steel wire mesh can be coated with PVC (Polyvinyl Chloride). This coating also adds aesthetic appeal, as it comes in various colors. 3. Stainless Steel: Wire mesh made from stainless steel offers exceptional durability and resistance to corrosion. It can withstand extreme temperatures, making it suitable for both indoor and outdoor applications. Industries such as food processing, pharmaceutical, and architecture commonly use stainless steel wire mesh. 4. Epoxy Coating: For extra protection against corrosion, chemicals, and abrasion, the steel wire mesh is coated with epoxy-based paint. This finish is often utilized in industrial settings, wastewater treatment plants, and marine environments. 5. Powder Coating: By applying a layer of polyester or epoxy powder, which is then cured under heat, the steel wire mesh achieves a smooth and durable finish. Powder coating improves resistance to corrosion, chemicals, and UV rays while offering attractive appearance and color options. These various finishes provide a wide range of choices to meet different application requirements, ensuring optimal performance, longevity, and aesthetics. To determine the most suitable finish for your specific needs, it is crucial to consider the project's requirements and consult with a professional.

- Q:What are the different mesh opening patterns available for steel wire mesh?

- Some of the different mesh opening patterns available for steel wire mesh include square, rectangular, diamond, hexagonal, and oblong shapes.

- Q:How does steel wire mesh perform in terms of transparency?

- Steel wire mesh does not possess transparency as it comprises interwoven steel wires that form a grid-like pattern, blocking the passage of light. Its sturdy composition makes it suitable for applications necessitating strength and durability rather than visibility. Nonetheless, some variations of wire mesh feature smaller openings that offer a certain level of visibility, albeit limited compared to materials explicitly designed for transparency, such as glass or clear plastics.

- Q:Is steel wire mesh resistant to rust or oxidation?

- Steel wire mesh is known for its resistance to rust and oxidation. This is due to its composition, as it is usually made from stainless steel, which has a high chromium content. Chromium forms a protective layer on the surface of the material, providing excellent resistance against rust and corrosion. This layer acts as a barrier, preventing oxygen and moisture from reaching the steel and causing oxidation. Hence, steel wire mesh is a great choice for applications requiring resistance to rust and oxidation, such as outdoor structures, fencing, and industrial use. However, it is important to remember that even stainless steel can still be susceptible to rust and oxidation under extreme conditions or when exposed to corrosive substances. Regular cleaning and maintenance can help extend the lifespan and maintain the appearance of steel wire mesh.

- Q:Can steel wire mesh be used for conveyor belts?

- Yes, steel wire mesh can be used for conveyor belts. Steel wire mesh is a durable and sturdy material that can withstand heavy loads and high temperatures, making it suitable for conveyor belt applications. It provides excellent strength and flexibility, allowing for smooth and efficient movement of materials along the conveyor system. Additionally, the open design of steel wire mesh allows for easy cleaning and drainage, making it ideal for industries such as food processing and agriculture. Overall, steel wire mesh is a reliable and versatile option for conveyor belts.

- Q:What are the different types of weaves available for steel wire mesh?

- There are several different types of weaves available for steel wire mesh, each serving a specific purpose and offering unique characteristics. Some of the most common types include: 1. Plain Weave: This is the simplest and most common weave pattern, where each wire passes alternately over and under the adjacent wires, creating a strong and durable mesh. 2. Twill Weave: In this weave pattern, each wire passes over two and under two adjacent wires, creating a diagonal pattern. Twill weave offers increased strength and stability compared to plain weave. 3. Dutch Weave: This weave pattern uses thinner wires in the warp direction and thicker wires in the weft direction, resulting in a tighter mesh. Dutch weave is commonly used for filtration applications where a fine and precise filtration is required. 4. Twilled Dutch Weave: Combining the characteristics of twill weave and Dutch weave, this pattern provides excellent strength and filtration capabilities. It has a double layer of warp wires and is commonly used in applications requiring high filtration efficiency. 5. Reverse Dutch Weave: In this weave pattern, the thickest wires are used in the warp direction, while thinner wires are used in the weft direction. This creates a tight weave with small openings, making it suitable for applications that require high strength and fine filtration. 6. Welded Wire Mesh: Instead of weaving, this type of mesh is created by welding intersecting wires together, forming a grid-like pattern. Welded wire mesh offers high strength and stability, making it ideal for applications requiring a rigid structure. These are just a few examples of the different types of weaves available for steel wire mesh. The choice of weave depends on the specific requirements of the application, such as filtration needs, strength, durability, or the desired aesthetic appearance.

- Q:What are the different wire mesh finishes available in steel wire mesh?

- There are several different wire mesh finishes available in steel wire mesh, including galvanized, PVC coated, epoxy coated, and stainless steel.

- Q:How is steel wire mesh used in geotechnical engineering?

- Various applications in geotechnical engineering commonly utilize steel wire mesh. Soil stabilization is one primary use where the mesh reinforces weak or loose soil, preventing slope instability and erosion. This reinforcement is achieved through horizontal or vertical installation of the mesh, creating a strong barrier that retains the soil's shape and prevents movement. Steel wire mesh is also employed in the construction of retaining walls and embankments. These structures are built to withhold soil or rock masses, preventing landslides and collapses. The mesh is installed within or behind the retaining wall, reinforcing it and distributing the forces exerted by the soil or rock mass evenly, reducing the risk of failure. Additionally, erosion control systems utilize steel wire mesh. It is installed on slopes or riverbanks to protect the soil from erosion caused by water or wind. Acting as a barrier, the mesh prevents the washing away or blowing off of soil particles. By stabilizing the soil and reducing erosion, steel wire mesh maintains the integrity of the landscape and prevents environmental damage. Furthermore, rockfall protection in geotechnical engineering utilizes steel wire mesh. In areas prone to rockfall, such as mountainous regions or highways, the mesh is installed to catch and contain falling rocks. Anchored to the slope or cliff face, it creates a protective barrier, preventing rocks from reaching the ground and posing a hazard to people or structures below. In summary, steel wire mesh serves a crucial role in geotechnical engineering, providing reinforcement, stability, and protection to various structures and landscapes. Its durability and versatility make it the preferred choice for applications requiring strength and resistance to environmental factors.

- Q:How is steel wire mesh used in animal enclosures?

- Steel wire mesh is commonly used in animal enclosures due to its strength and durability. It provides a secure barrier that prevents animals from escaping while allowing for proper ventilation and visibility. In zoos and wildlife reserves, steel wire mesh is used to create enclosures for a variety of animals, ranging from small birds and reptiles to large mammals. The mesh is typically woven tightly, preventing small animals from squeezing through and ensuring their safety. Steel wire mesh is also used in agricultural settings, such as poultry farms and livestock enclosures. It is used to create pens and cages that keep animals contained and protected from predators. The mesh allows farmers to easily monitor their animals and provides a safe environment for them to roam and graze. Additionally, steel wire mesh is used in pet enclosures and kennels. It is commonly seen in dog runs and outdoor cat enclosures, providing a secure and spacious area for pets to exercise and play. The mesh is strong enough to withstand scratching and chewing, ensuring that pets stay contained and safe. Overall, steel wire mesh is a versatile material that is widely used in animal enclosures. Its strength, durability, and flexibility make it ideal for creating secure and comfortable habitats for a variety of animals, from small pets to large wildlife.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mesh Green Vinyl Coated Hardware Cloth with Differnent Gauges

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords