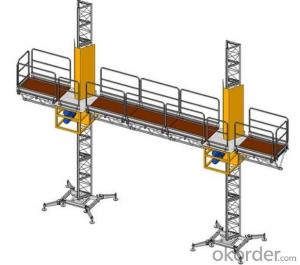

Mast Climbing Working Platform

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

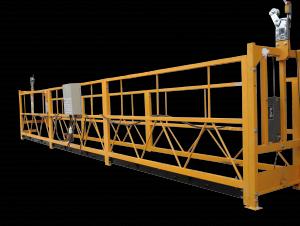

Mast Climbing Work Platforms run vertically by rack that is installed to hot dip galvanized masts driven by electrical engine with reduction gears and pinion. These systems provide quick, safe and comfortable access to façade.

- Main mechanism is embedded to hot dip galvanized masts by means of wheels. All electrical engines, reduction gears, electrical and other main components are found on the main mechanism. It also provides 1.3 m long platform.

- Main unit in installed on trailer in order to transfer the system easier.

- There are 4 units of lever jacks in order to balance the mechanism.

- There is 220 Volt 50-60 Hz electricity plug on the control panel. Outside electricity resource is no needed.

- According to project the system can be installed as single or double mast. Maximum platform length is 7,5m for single mast installation. In double mast installation the maximum platform length is 21m.

- Platform length is adjustable according to project with 1.3m long and 0.8m long modular platforms.

- Width of the platform is 1 meter. This width can increased up to 2 m with standard extension equipment and to 3 meter by extra optional extension components. This provides more space and access to façade where there are cantilevers or alcoves.

- The capacity of the system is 350 kg in single mast 1000kg in double mast.

- There is a balance switch and balance bar for double mast installations in order to balance the machine.

- Length of each mast is 1,50m and 48 kg.

- Masts are coated with hot dip galvanization.

- Masts are connected to each other with 8.8 quality bolts, nuts and lock washers.

- System is tested up to 75 m height. Anchoring of the masts is required in every 6 meter. With single anchorage it can climb up to 12m.

- We provide project services for anchoring and façade placement.

- All anchoring components such as anchorage pipes, connecting components, wall couplings etc. are provided.

- The vertical speed of the system is 9m/min.

- All parts and components of the system is designed as modular for easy installation. Installation and reinstallation is much easier and faster comparing other façade access system.

ELECTRICAL ENGINES and REDUCTION GEARS

- WAT/GAMAK brand electrical engines and Yilmaz/PGR brand reduction gears are used in our products.

- 3 kW 380 Volt 50-60 Hz 3 phase electrical engines are used for in single mechanism. There are two main mechanisms in double masts installation.

- All electrical engines are equipped with CE certificated magnetic breaks.

- All needed domestic and international quality and other certification is available for the engines.

ELECTRICAL COMPONENTS and FEATURES

- Schneider brand components and equipment are used in all control panels.

- Low voltage is used in control panels in order to avoid accidents.

- Phase line control equipment is available.

- High and low voltage control switch is available.

- Certified and qualified electricity cables.

- All control panels and electricity boxes are IP65 class protection certified.

- Electrical engines are IP55 class protection certified.

SAFETY EQUIPMENTS and FEATURES

- Independent emergency parachute break on main mechanism.

- Limit switches stops the machine both upward and downwards movements.

- Extra emergency limit switch which stops the machine completely incase of failure of limit switches.

- Control of mast presence switch.

- Balance bar and balance switch for automatic levelling for double mast installations.

- Emergency Stop.

- High and low voltage protection,

- CE certificated magnetic breaks

- Manual descent equipment for power failure situations.

- Acoustic signal before and during movements.

- Permanent acoustic signal during descending.

- Phase line control equipment.

- Low voltage electrical panel.

- Mast access is block with perforated plate.

- All required warning signs for operators.

COATING and FINISH

- All masts are coated with hot dip galvanization.

- Racks are electroplated.

- All anchorage equipment are electroplated.

- All platforms’ steel structure is coated with hot dip galvanization.

- Safety fences are electroplated.

- Perforated plates are electroplated.

- Main Chassis of the main mechanism is coated with hot dip galvanization.

- Main mechanism is coated with electrostatic paint.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mast Climbing Working Platform

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords